The Tailored System for Sophisticated Residual Gas Measurement

Our OmniGrade is the customized complete solution for cleanliness verification – individually configured and optimized for you by our experts

:grayscale(false):format(png))

Purity testing with in-depth knowledge of residual gas analysis (RGA)

Rapidly expanding markets with ever more stringent technical requirements are placing increasing emphasis on the highest level of cleanliness, as molecular contamination affects the functionality of their products. The key to professional quality assurance lies in correctly determining the outgassing rates using mass spectrometry under high vacuum conditions.

We have been supporting our customers for many years with an extensive portfolio of analysis devices for residual gas analysis. The testing requirements also change over time. With our OmniGrade, we are expanding our portfolio of products for residual gas analysis in order to offer a higher level of value creation and thus increase the benefits for our customers.

:grayscale(false):format(png))

Brochure: OmniGrade

RGA systems based on a modular principle for every testing requirement

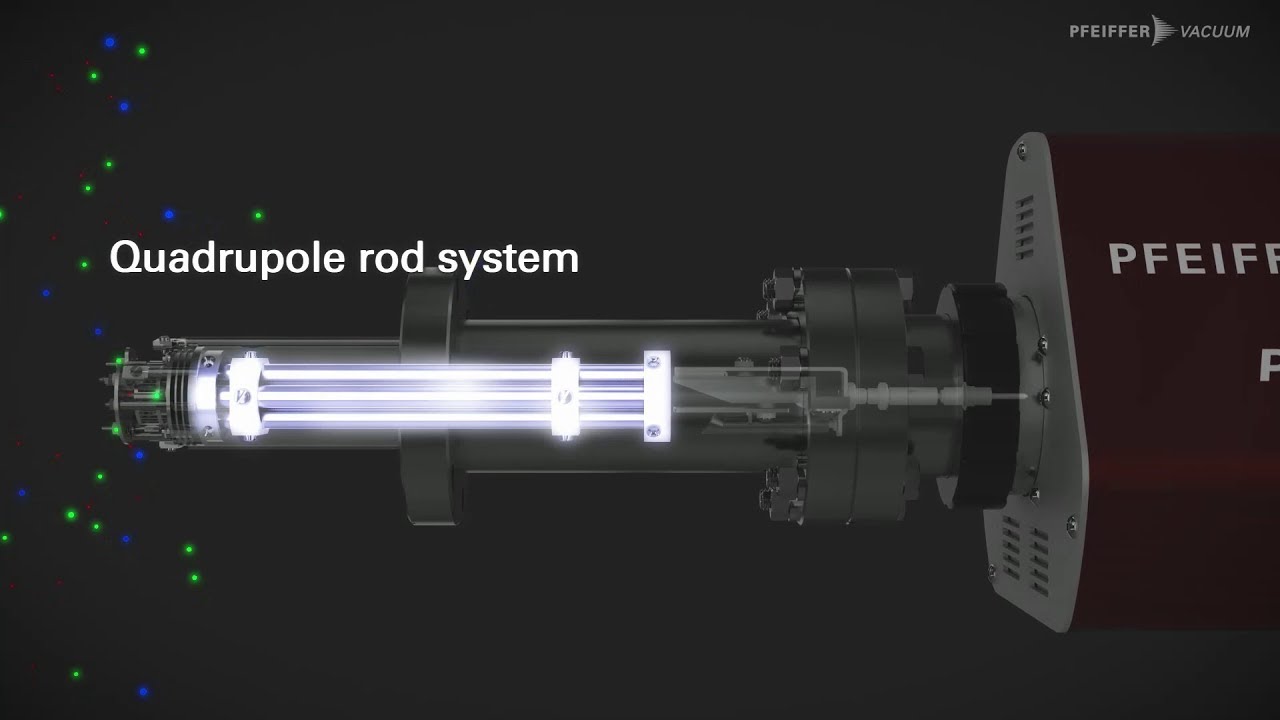

Every test task is different. Our team of experts accesses the full range of Pfeiffer Vacuum products and uses them to configure the system that best suits your requirements. Not only are the individual components such as quadrupole mass spectrometers, vacuum pumps, chambers and other individual components selected for your OmniGrade , but the total operating costs and delivery times of the tailor-made, turnkey solution are also taken into account. With our expertise, we can help you achieve test results with the precision you need while minimizing unnecessary effort.

Precision made to measure

The selection of the quadrupole mass spectrometer (PrismaPro or HiQuad) and the determination of the number of chambers have a significant influence on the achievable detection limit. In the standard system there are two chambers, one in which the test specimen lies and one in which the spectrometer is located. If necessary, this structure can be supplemented with a third chamber, the lock chamber. This avoids contamination of the measuring chamber from the environment and significantly reduces the background. By baking out the system, it is optimally conditioned, which further increases the measurement capability.

Your OmniGrade benefits

Execution tailored to your needs using a modular system

Low detection limits possible

Fully automated measuring process

Worldwide service network

Testing according to GSA 07 1221 & GSA 07 2221

Applications and areas of application of the OmniGrade residual gas analysis

EUV lithography in semiconductor production

Electron microscopy

Applications in ultra-high vacuum (UHV)

Would you like to find out more about the individual components?

Mass spectrometry with PrismaPro or HiQuad

Dry backing pumps

Do you want to know more? Please feel free to contact us, we look forward to your requirements!

Functional principle of the PrismaPro quadrupole mass spectrometer

Speaking of tailor-made systems

In the area of customized systems, we have even more to offer beyond residual gas analysis systems. Our knowledge of the requirements of the semiconductor, pharmaceutical, metallurgical and emerging markets, acquired over many years of experience, goes into the development of state-of-the-art systems that help you assert yourself in your industry. For example, we have developed contamination management systems that aim to identify and minimize contaminants and optimize production processes at every stage. For higher yields through improved quality and shorter cycle times.

Partially assembled modules for leak test tasks

In addition to self-sufficient units, we also offer modular solutions that you can integrate into your system. This includes, among others, our leak test module (LTM for short), which you can integrate into your production line for series production. For pre-series production, it is also available as an individual test stand for manual qualification. The customer-specific configurable modules can cover the full range of test methods and parameters, and are partially assembled by us. With our experience in mechanical and software integration, we support our customers in implementing their solution.

Brochures

Need any help?

We are available for your questions

Our team of product experts is always available to answer your questions about our products and your applications.

:grayscale(false):format(png))

:grayscale(false):format(png))

:grayscale(false):format(png))