More Efficiency And Performance With Pfeiffer Vacuum Screw Pumps

With the screw pumps from Pfeiffer Vacuum you get modern vacuum pumps for industry that have been developed for high vapor and particle compatibility. Our pump supplies your process with almost constant pumping speed.

:grayscale(false):format(png))

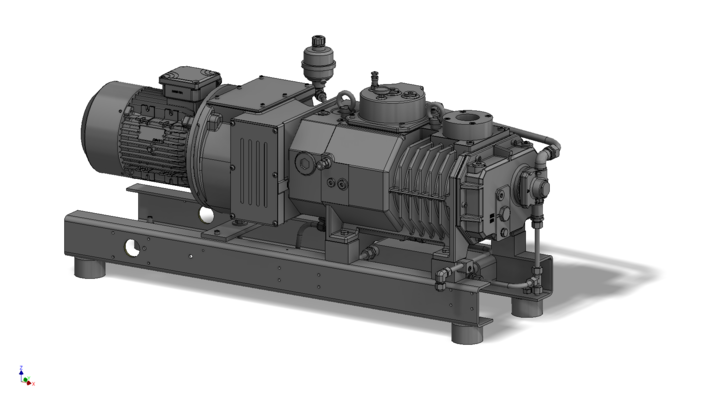

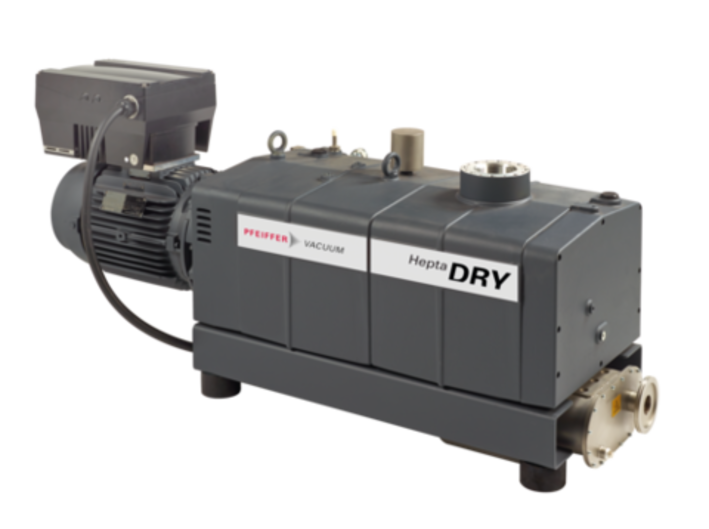

Dry and robust screw pumps

Due to their wide range of pumping speeds, the series of HeptaDry dry screw pumps is ideal for applications in both rough and fine vacuum in industry. It can be used for a variety of industrial applications such as freeze drying, metallurgy and coating. HeptaDry is the ideal solution for areas where an oil-free vacuum is required. The pumping speed of this product range ranges from 100 to 630 m3/h.

The one-piece rotors with variable pitch are a particular advantage. They ensure the necessary internal compression of the HeptaDry pumps. In addition, the variable pitch of the screw rotors results in lower power consumption compared to constant pitch screw rotors as well as low cooling water consumption, making the vacuum pump an economical solution. The innovative design and low speed of the pumps ensure low stress on the bearings and seals.

Our screw pumps from the HeptaDry series are ideal for use as individual pumps or in combination with our HiLobe Roots pumps in various areas of application.

:grayscale(false):format(png))

Brochure: HeptaDry

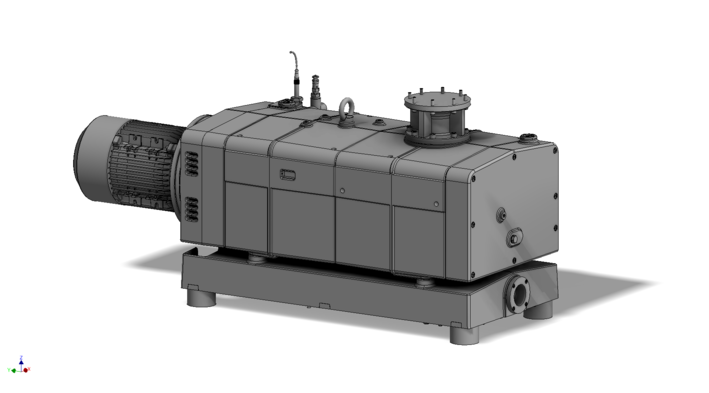

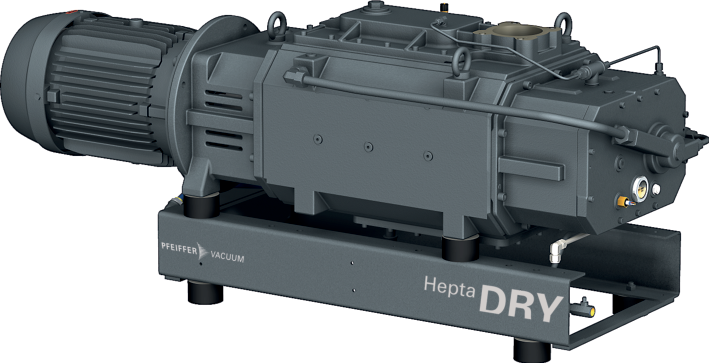

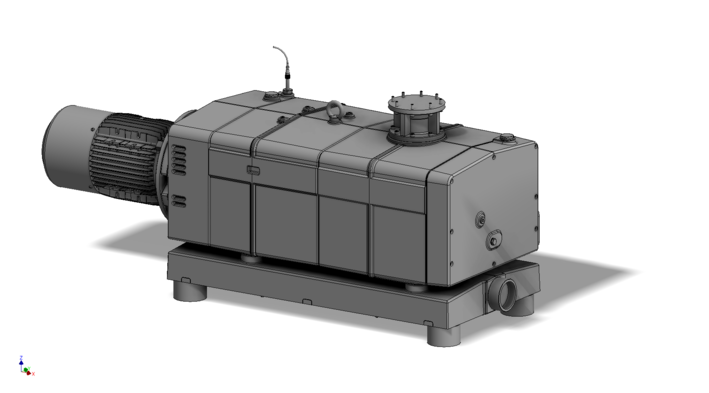

Screw pump in two different versions

The HeptaDry is available in two different versions in order to offer the right solution for as many applications as possible.

The two options differ in terms of accessories, motors, inlet and outlet, and much more. They can each be configured as required in consultation with our experts.

Maintenance of screw pumps

In addition to extending its service life, regular maintenance of a screw pump ensures that the pump can be used effectively and reliably in the process and that it delivers the desired performance even after a long period of use:

Accessories

Dust separators (SAS) can be mounted on the inlet side, which protect the pump from particles from the process. Different versions are available depending on the pump's connection flange. A silencer can be added to the exhaust side to reduce the noise level. In addition, on some models it is possible to provide a check valve between this and the pump, which serves to protect the vacuum pump from returning condensate and particles. The temperature of the motor winding can be monitored and the motor can be protected using a PTC tripping device.

The accessories, in addition to the configuration tailored to your application, can lead to increased safety and service life if used correctly. Our experts are also happy to answer any questions you may have about accessories.

:grayscale(false):format(png))

:grayscale(false):format(png))