Turbopumps

:grayscale(false):format(png))

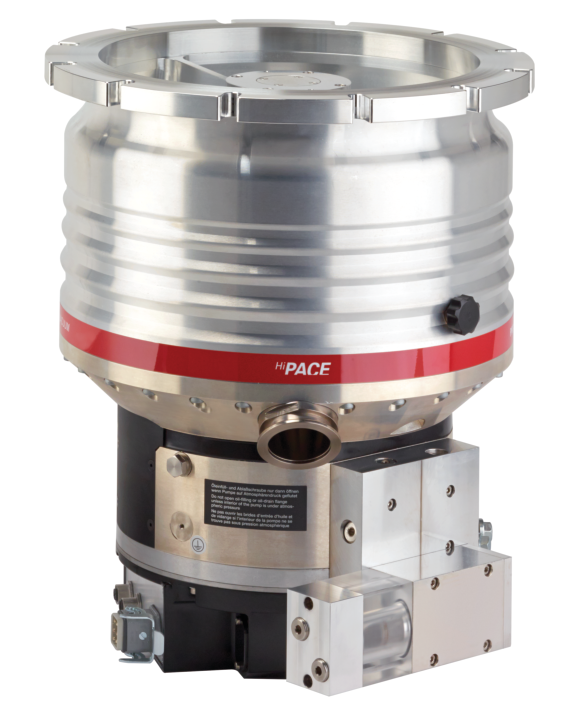

Turbomolecular pumps as the technological standard

Turbomolecular pumps (also called turbopumps), which owe their name to the related turbines, have established themselves worldwide as the technological standard for vacuum generation in industry and research. Developed in 1958 by Pfeiffer Vacuum engineer Dr. Willi Becker, turbopumps feature high-speed rotors. At up to 90,000 revolutions per minute, these generate a vacuum of less than 10-11 hPa - and thus ideal pressure conditions for your applications, e.g. high vacuum (HV), ultra-high vacuum (UHV) or extremely high vacuum (XHV).

A game-changing enabler in vacuum technology

The HiPace 10 Neo is not only unique because it is unrivalled in its class but is also particularly suitable for mobile applications thanks to its mechanical bearing and large thermal operating range.

Turbomolecular vacuum pump:

Working principle simply explained

Turbopumps belong to the group of kinetic vacuum pumps. The design resembles that of a turbine, consisting of a multistage, turbine-like rotor with bladed disks rotating in a housing. Likewise bladed stator disks of similar geometry are arranged in mirror-image fashion between the rotor disks. When a gas particle, thus, hits the rotor blade, the impact accelerates it in the direction of rotation (i.e., the pumping direction). The blades of the next stator disk guide it further in the pumping direction, where it is led to the next rotor disk and receives another push.

Do you want to learn more about how turbomolecular pumps work and how to apply them? Learn everything you need to know about Pfeiffer Vacuum turbopumps and their usage with our turbopump training course. Further detailed information can also be found in our Knowhow section.

Take a look inside the HiPace turbopump from Pfeiffer Vacuum and get to know its components and functions!

What are the advantages of Pfeiffer Vacuum turbopumps?

They are the secret stars behind the scenes: Although they often go unrecognized, turbopumps contribute significantly to ensuring trouble- and error-free processes. This makes them an important success factor for your production processes and research projects. If you are active in one of the industries listed above, vacuum is indispensable for you to establish the necessary working and production conditions. Semiconductor production or electron microscopy, for example, would be inconceivable or even impossible to implement without the use of turbopumps.

Thanks to their sophisticated rotor design, turbomolecular pumps from Pfeiffer Vacuum score highly in terms of pumping speed, backing pump compatibility, gas throughput and compression. When it comes to high, ultra-high and extremely high vacuum generation, Pfeiffer Vacuum turbopumps offer you all the reasons to rely on us:

Optimal operating conditions: up to 90,000 rpm for the generation of high, ultra-high and extremely high vacuums of up to <10-11 hPa and pumping speeds of 10 to > 3,000 l/s

High efficiency due to excellent quality: up to 100,000+ h of trouble-free operating time

High flexibility: Due their compact & lightweight design, you can integrate our turbopumps even into systems with limited space. With their IP54 rating the pumps are particularly designed for industrial use.

Reduced production downtime: Simply replace bearings and operating materials directly in the production field.

State-of-the-art drive electronics: reduce loss of power transmission, enable maximum energy efficiency and integration of the latest fieldbus systems

Vibration- and noise-reduced operation: Thanks to our high-precision laser balancing method, our turbopumps are ideally suited for use in vibration-sensitive applications.

What makes the new Pfeiffer Vacuum laser balancing method special?

As Pfeiffer Vacuum’s latest innovation, the laser balancing method sets new milestones in the production of turbopumps. Unlike conventional balancing methods, laser balancing eliminates the necessity of balancing weights installation or mechanical milling processes. Instead, a high-precision laser vaporizes material in the balancing planes efficiently and precisely, thanks to its flexible applicability and state-of-the-art measurement and calculation algorithms. Residual unbalance is, thus, significantly lower than with conventional balancing. The result: a low-vibration turbo pump with extended service life and reduced noise emission – ideal for devices and applications requiring low vibration.

The new Laser BalancingTM technology

We take a look behind the scenes at Pfeiffer Vacuum GmbH and show you how new technologies are developed.

Pfeiffer Vacuum turbopumps – Choose between hybrid and magnetic bearings

Turbopumps from Pfeiffer Vacuum are available with two different bearing technologies: a hybrid bearing suspension and an active 5-axis magnetic levitation system. Both bearing systems convince with their individual strengths.

Turbopumps with hybrid bearing

Turbopumps with hybrid bearings feature a combination of ceramic ball bearings on the fore-vacuum side and permanent magnet bearings on the high vacuum side. This combination provides an extremely robust and clean rotor bearing arrangement. With its integrated operating fluid reservoir, the rotor can easily dissipate heat and operate reliably. Abrasion particles are filtered out through the operating fluid reservoir, increasing the total service life. As the inventor of the hybrid bearings, Pfeiffer Vacuum is a pioneer in this highly efficient bearing technology. Looking back at 40 years of manufacture experience, you can rely on the quality of our hybrid bearing turbopumps.

:grayscale(false):format(png))

Cutaway view of a hybrid turbopump

Magnetically levitated turbopumps

Magnetically levitated turbopumps feature a rotor held in suspension by electromagnets and a digital electronic control system which ensure there are no mechanical points of contact between rotor and outer casing. Additionally, in the event of power failure, power is supplied by the rotational energy of the turbopump itself until the rotor lands securely on the emergency bearings. These features protect the rotor from premature wear and allow maintenance-free use throughout the entire service life. In addition, magnetic bearing turbopumps do not require lubricants, which eliminates the risk of hydrocarbon contamination.

:grayscale(false):format(png))

Cutaway view of a magnetically levitated turbopump

Where are turbopumps used?

Vacuum technology plays a vital role in industrial manufacturing processes as well as in multiple areas of technical research.

You might want to use Pfeiffer Vacuum’s turbopumps in the following fields of application:

More safety in the workplace with certified turbopumps from Pfeiffer Vacuum

Modern turbopumps can reach speeds of up to 1,500 Hz. The kinetic energy, therefore, is correspondingly high, resulting in extreme forces acting on the pump housing and anchoring within a fraction of a second in case of fault.

To guarantee your safety at work, Pfeiffer Vacuum has developed a safety certification in collaboration with TÜV Rheinland, which includes dual protection against overspeed in addition to mechanical safety. Since Pfeiffer Vacuum turbopumps are designed for a particularly long service life, we evaluate and certify our turbomolecular pumps in accordance with UL 61010 and Semi S2 guidelines, respectively, to ensure safe usage.

:grayscale(false):format(png))

:grayscale(false):format(png))

:grayscale(false):format(png))

:grayscale(false):format(png))

:grayscale(false):format(png))

:grayscale(false):format(png))

:grayscale(false):format(png))

:grayscale(false):format(png))

:grayscale(false):format(png))

:grayscale(false):format(png))

:grayscale(false):format(png))

:grayscale(false):format(png))

:grayscale(false):format(png))

:grayscale(false):format(png))