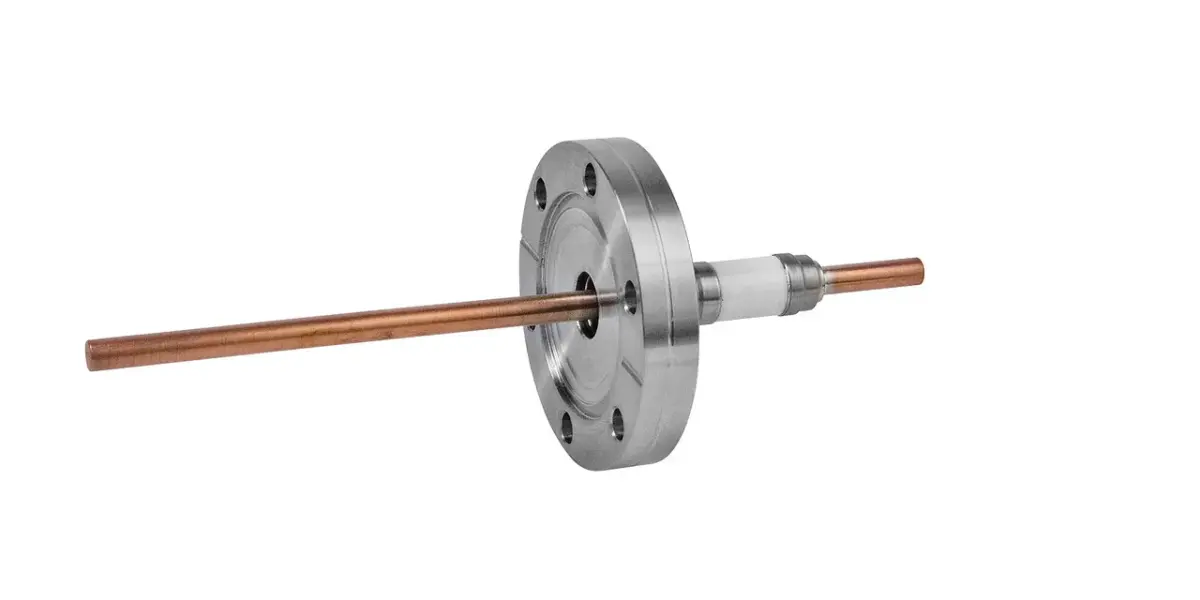

3.5 Components and feedthroughs

A vacuum system has a number of single components that must be assembled to form a unit. With detachable, vacuum-sealed flange connections, components can be connected directly or through vacuum components, such as piping components or hoses. There are a number of standard components available, which are mainly made of stainless steel but also from aluminum. Vacuum junctions can be made from pipe components such as elbows, T- or cross-pieces, and adapters provide transitions from vacuum flanges to threads or VCR connections, and reducers or adapter pieces make it possible to change the nominal diameters or the flange systems.If the mounting space is limited, the fewest possible flange connections should be installed; if the required adapter and connections cannot be realized with the standard components, custom components are used. These start with special-length full nipples and end with highly complex, individual special solutions.