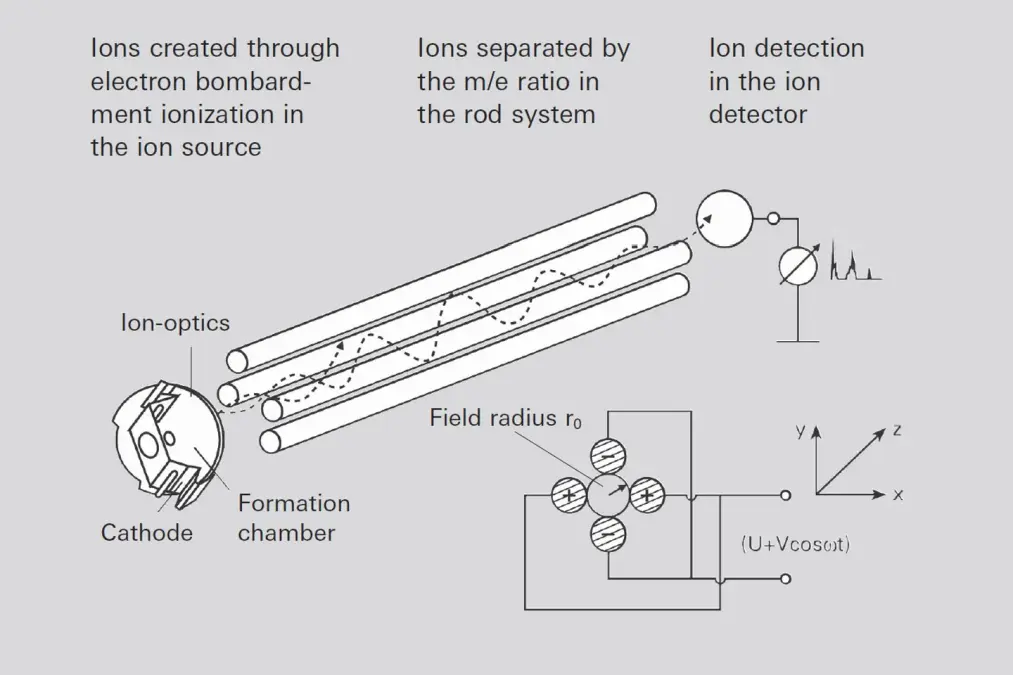

U= 1.2122 · 10-8

\frac{\mbox{kg}}{\mbox{A}\cdot\mbox{s}}\cdot M\cdot r_0^2\cdot f^2

V= 7.2226 · 10-8

\frac{\mbox{kg}}{\mbox{A}\cdot\mbox{s}}\cdot M\cdot r_0^2\cdot f^2

Material | Temperature | Applicable gases | Remarks |

|---|---|---|---|

Y2 O3 / lr | 1,300 °C | Inert gases, air / O2, NOx, SOx | Short service life with halogens, insensitive to high O2 concentrations, generates some CO / CO2 from O2 or H2O background |

W | 1,800 °C | Inert gases, H2, halogens, freons | Short service life with O2 applications, generates some CO / CO2, from O2 or H2O background, C causes brittleness |

Re | 1,800 °C | Inert gases, hydrocarbons, H2, halogens, freons | Service life around three months due to vaporization of the material, used with hydrocarbons |

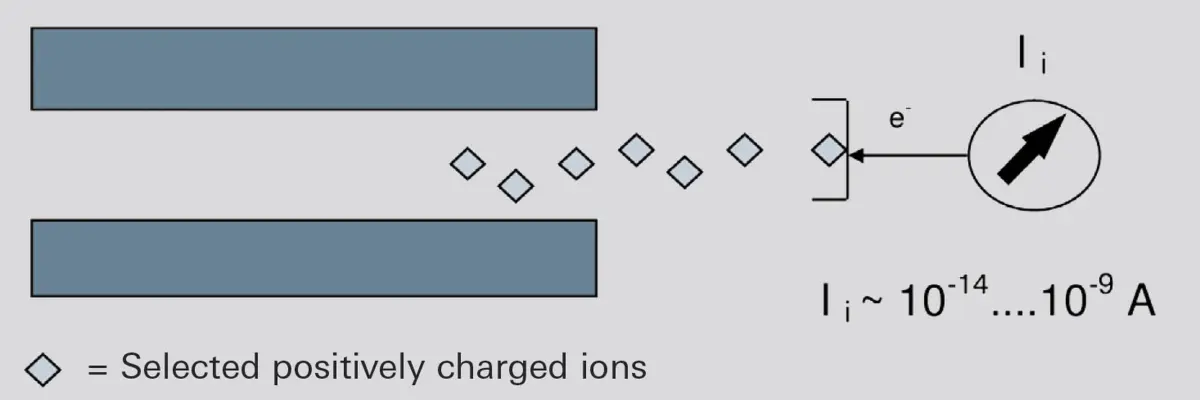

PrismaPlus | HiQuad with SEM 217 | HiQuad with SEM 218 | |

|---|---|---|---|

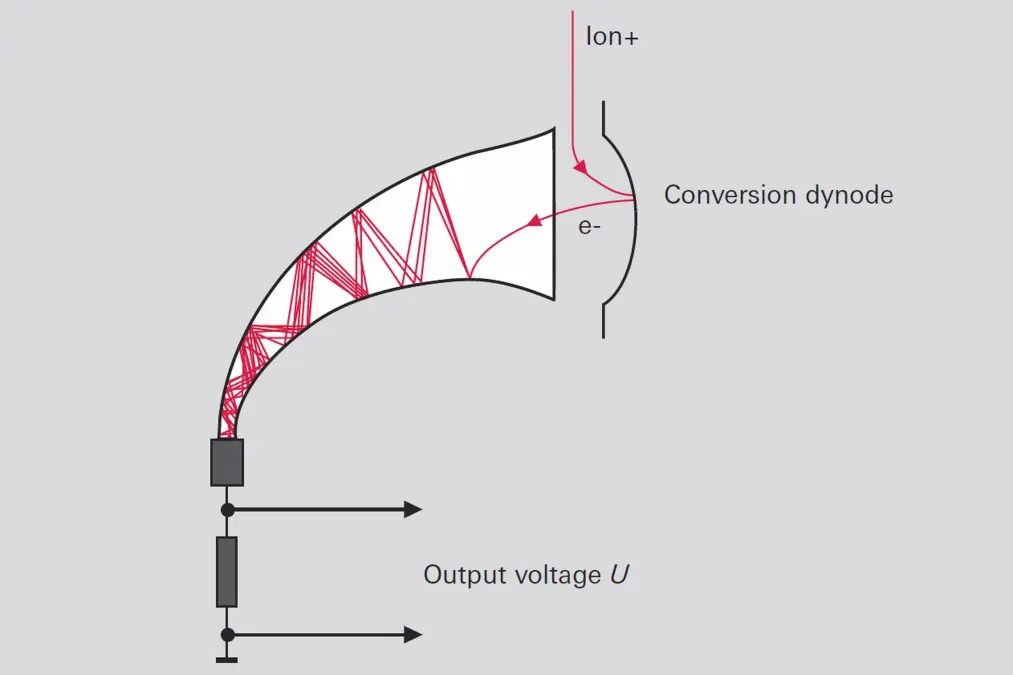

Detectors | Faraday / C-SEM | Faraday / SEM | Faraday / SEM with conversion dynode |

Maximum pressure for Faraday cup | 10-3 hPa | 10-4 hPa | 10-4 hPa |

Maximum pressure for SEM, C-SEM | 10-5 hPa | 10-5 hPa | 10-5 hPa |

Maximum measuring speed / u | 2 ms | 125 µs | 125 µs |

Bake-out temperature (max.) | 300 °C | 400 °C | 400 °C |

Counting operation | No | Yes (optional) | Yes (optional) |

Detection of positive ions | Yes | Yes | Yes |

Detection of negative ions | No | Yes | No |

Inlet system | Pressure range | Product example | Characteristics |

|---|---|---|---|

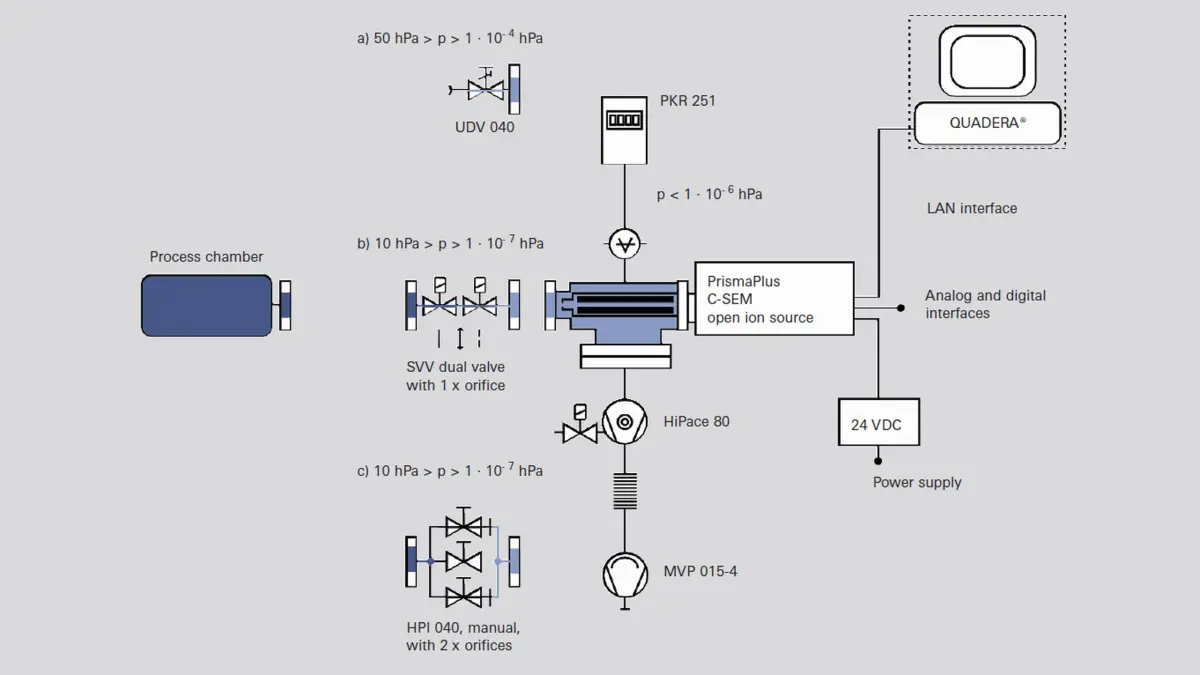

No pressure reduction | 10 -12 to 10 - 4 hPa | PrismaPlus QMG 220, HiQuad QMG 700 | Open construction ion sources to allow gas from anywhere in the system to be represented in the ionizer volume. |

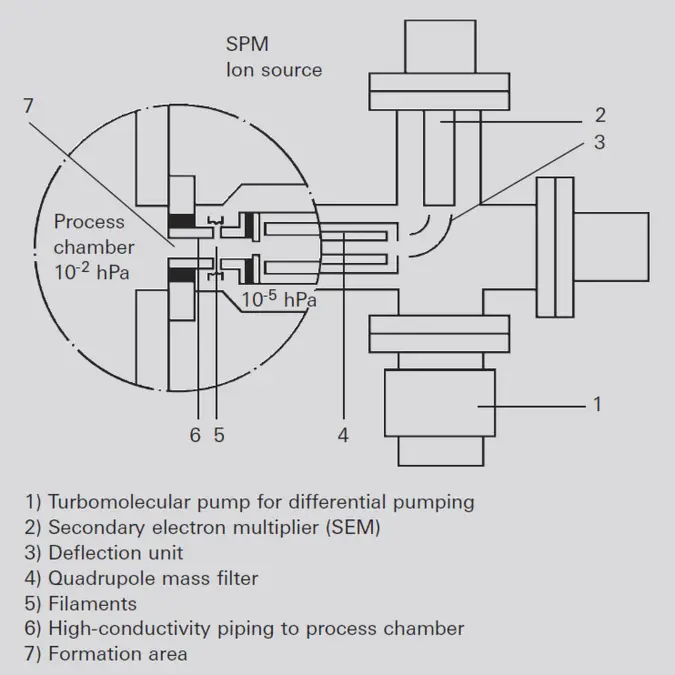

SPM ion source | 10 - 9 to 10 hPa | PrismaPlus SPM 220, HiQuad SPM 700 | Special ion source for analyzing sputter processes. This system analyzes gas directly at the sputter pressure of 10-2 hPa with no pressure reduction. |

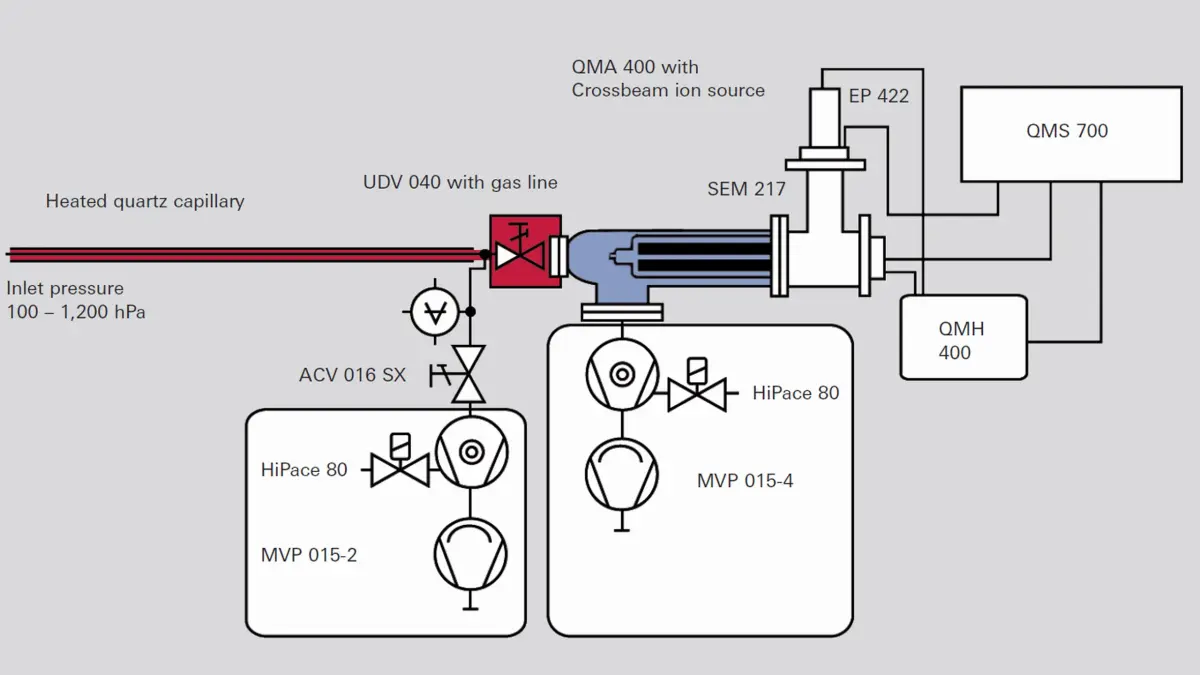

Capillary inlet | 100 to 1,100 hPa, depending on the capillary length and the downstream orifice | OmniStar, ThermoStar, Inlet system GES 020 and GES 010 | Differentially pumped inlet system, low mass discrimination, not suitable for varying sample pressures |

Orifice inlet | 0.01 to 10 hPa, as a function of orifice diameter | PrismaPlus HPA 220 | Orifices with diameters of 0.01 to 0.5 mm, simple, robust design, mass discrimination, changing inlet pressure possible with various orifice diameters, not suitable for fast-changing gas compositions |

Dosing valve | 0.1 to 1,000 hPa | PrismaPlus HPA 220, Gas dosing valves UDV 040, UDV 146 | Dosing valves are suitable for gas inlets over a very broad measurement range, differentially pumped valves also allow analysis of rapidly changing gas compositions |

Pressure-regulated gas inlet | 10 - 3 to 1,000 hPa | EVR 016 with RVC 300, OmniStar with pressure-regulated inlet | Differentially pumped inlet system, comprising a control loop with regulating valve and pressure measurement, relatively large dead volume, slow response |

-sev_news_article_1200x675.webp)