Herausforderungen bei der Erzeugung von Ultrahochvakuum

Um Ultrahochvakuum (UHV) – typischerweise definiert als Drücke unter 10⁻⁷ hPa (mbar) – zu erzeugen, ist ein präzises und abgestimmtes Systemdesign unerlässlich. Selbst kleinste Verunreinigungen können gravierende Auswirkungen haben: Ein einziger Fingerabdruck im Inneren der Kammer kann zu mehreren Stunden zusätzlicher Evakuierungszeit führen. Das macht deutlich, wie sauber, kontrolliert und sorgfältig geplant ein UHV-System von Anfang an sein muss.Wichtige Fragen, die während der Planungsphase berücksichtigt werden sollten, sind:

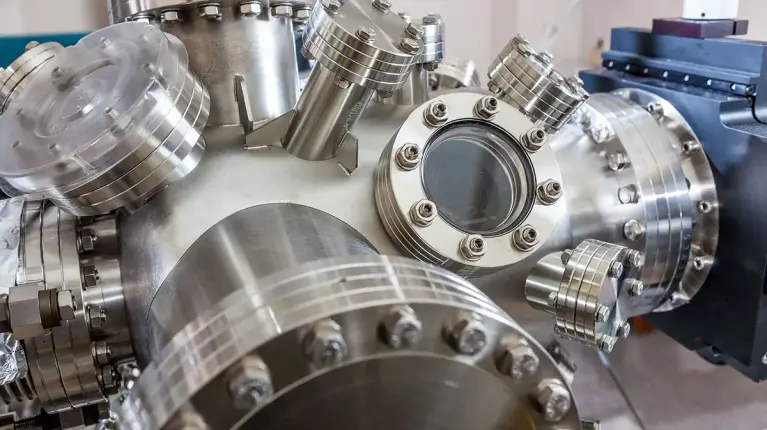

- Materialauswahl: Wie wirkt sich die Wahl des Materials auf das erreichbare Vakuumniveau und die Langzeitstabilität aus?

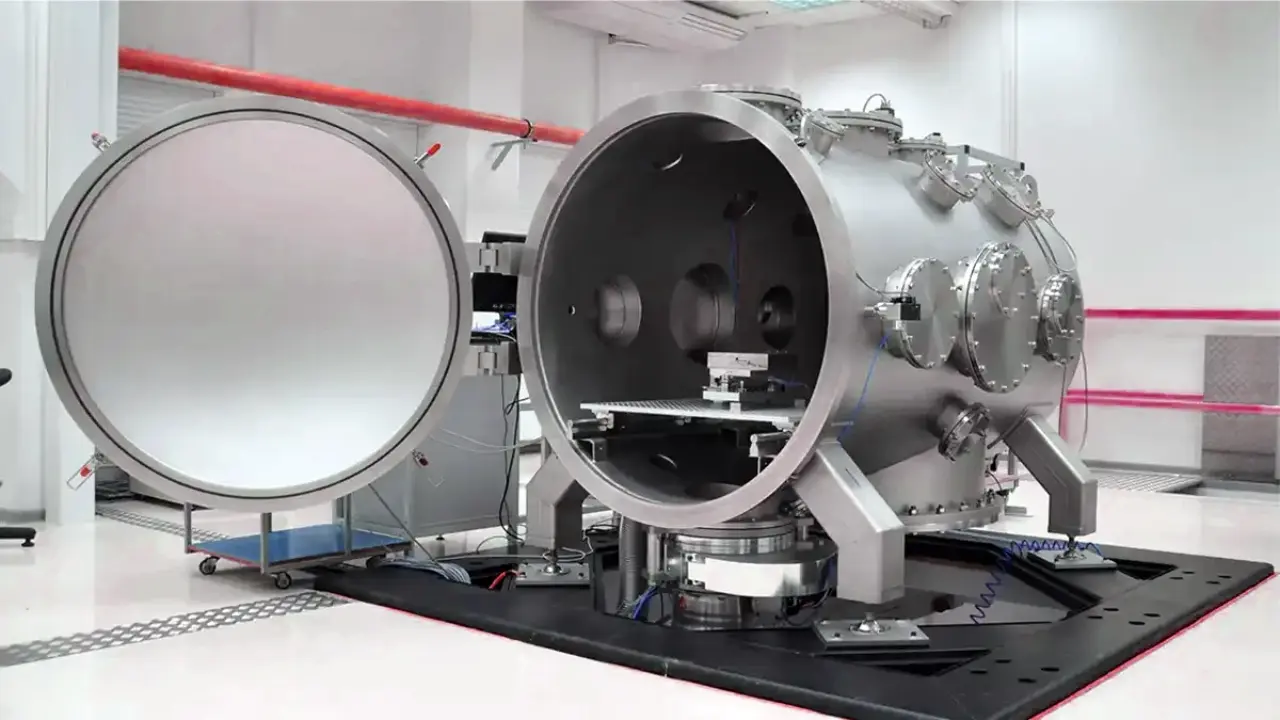

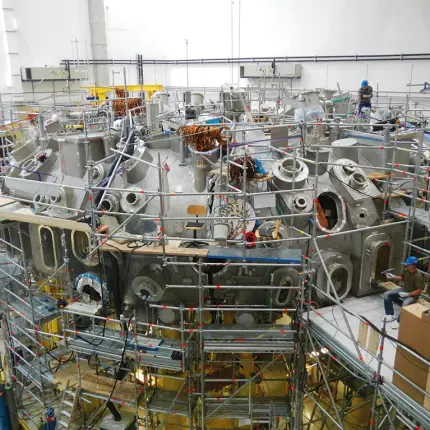

- Kammerdesign: Welche Rolle spielen das Design der Vakuumkammer und die Oberflächenbehandlung bei der Minimierung der Gaslast und der Vermeidung eingeschlossener Volumina?

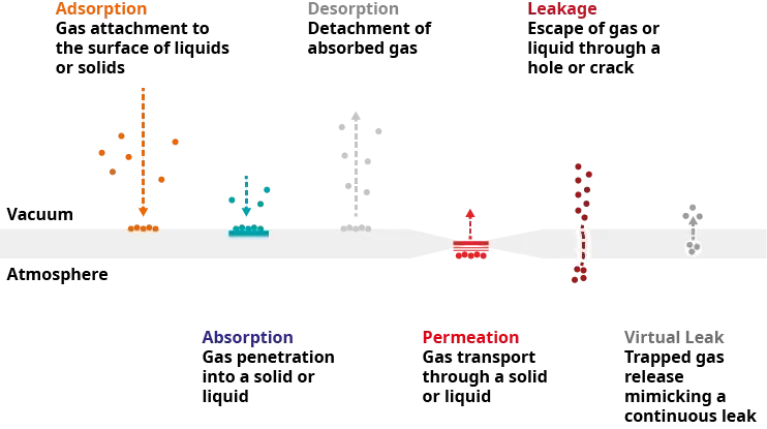

- Minimierung der Leckrate: Wie lassen sich potenzielle Undichtigkeiten bereits während der Montage erkennen und verhindern?

- Konfiguration der Vakuumpumpe: Welche Vakuumtechnologie und Verdichtungsverhältnisse sind erforderlich, um zuverlässig UHV-Bedingungen zu erreichen?