Two brands. One strong group.

The Busch Group is a world leader in vacuum solutions. We offer first-class turnkey solutions, exceptional service, and high-quality products. For every imaginable application and industry. Our two main brands are Pfeiffer Vacuum+Fab Solutions and Busch Vacuum Solutions.

History

-

1890: A bright idea sparks it all

It all began with the visionary mindset of a 23-year-old mechanic from Wetzlar in Germany. Arthur Pfeiffer founded the company in his own home, initially producing gas lamps and remote igniters. As electric light emerged, he immediately understood that this technology was the future – and that it had one major problem: the vacuum processes of the time were far too slow to keep pace with demand.

It took days to evacuate a single bulb and make it functional. Realizing that better, faster vacuum technology was essential for mass production and making electricity available for everybody, he set out to improve and refine the existing vacuum pumps. This marked the beginning of vacuum technology at what was then still called Arthur Pfeiffer.

-

1910: Turning ideas into innovation

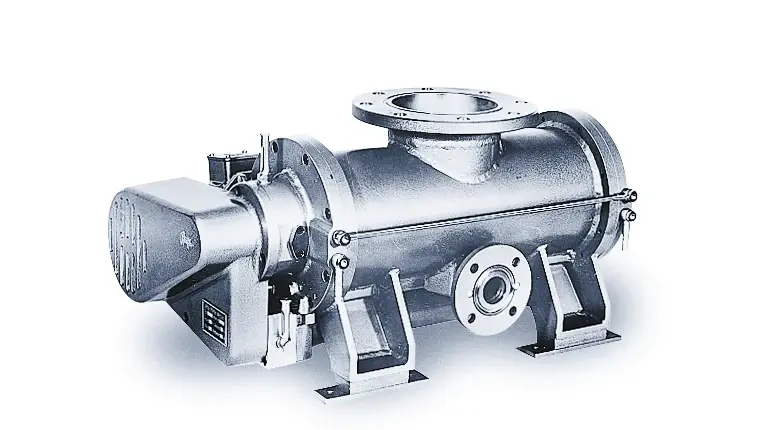

In 1910, Arthur Pfeiffer brought a groundbreaking idea to life: the rotating oil air pump, based on a concept by physicist and vacuum expert Wolfgang Gaede. It was the first oil-free vacuum pump – and delivered performance the world had not seen before. Primarily used to evacuate the latest tungsten filament light bulbs, it set a new benchmark in vacuum technology at the beginning of the 20th century.

-

1929: Going global

In 1929, Arthur Pfeiffer presented over 50 of his vacuum pumps – now also designed for the pharmaceutical and chemical industries – at an exhibition in Leningrad. It was the company's first international trade show participation, marking a bold step beyond national borders and introducing Pfeiffer technology to the international stage, setting the wheels in motion for a truly global journey.

-

1958: A revolutionary invention spins to life: the turbopump

In 1958, another mastermind set the stage for a revolution in vacuum technology. Dr. Willi Becker, head of the Pfeiffer lab, had long been searching for ways to improve the performance of diffusion pumps, which lost up to 50% efficiency due to gas flow-restricting baffles. In 1955, he made a groundbreaking discovery: a rotating disk with turbine blades could generate a powerful pumping effect.

Over the next few years, he refined this concept into a prototype using several high-speed rotating disks. The result was the turbomolecular vacuum pump. In 1958, the turbopump was patented and introduced to the market. For the first time, it was possible to reach vacuum levels that had previously been out of reach. Pfeiffer had set a new standard – and vacuum technology changed forever.

-

1978: A leap into space with NASA

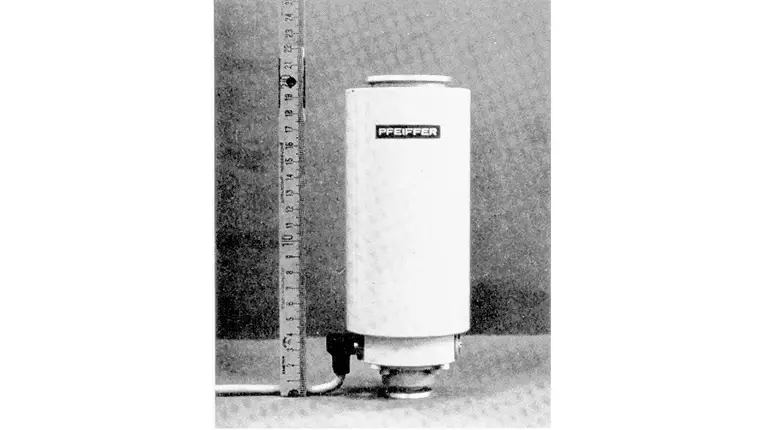

When NASA needed a tailor-made turbopump for a mission to Jupiter, they called Pfeiffer. The requirements were unlike anything before: the vacuum pump had to be tiny, energy-efficient, and capable of compressing hydrogen 100 times more than the standard at the time. After a bold pitch and 12 months of intense development, Pfeiffer delivered the TPU 25, which passed all tests with flying colors.

In doing so, the company proved that its pioneering vacuum technology was ready for the final frontier – and quite literally launched Pfeiffer into space.

-

1985: SplitFlow launch – tailored vacuum power for analytics

By 1985, Pfeiffer faced a growing challenge: analytical instruments like mass spectrometers and leak detectors demanded compact, powerful, and highly adaptable vacuum solutions. The answer was the SplitFlow turbopump – a breakthrough that did not just meet expectations but redefined them. Incorporating the hybrid bearing system also known from the HiPace turbopumps, the SplitFlow can effortlessly achieve high and even ultra-high vacuum levels, all while running with impressive energy efficiency.

Unlike conventional vacuum pumps that forced users to adjust settings or switch to special models, the modular design of the SplitFlow allows each pump to be customized like a precision tool, perfectly tailored to every process. Compact, flexible in all mounting positions, and equipped with smart system integration and real-time data monitoring, it quickly became the go-to choice for the analytical world.

-

2000: DigiLine – the digital revolution in vacuum measurement

At the turn of the millennium, Pfeiffer reshaped the industry once again with DigiLine, the world’s first complete digital vacuum gauge series. Until then, analog systems dominated, often struggling with complicated calibration, wiring complexity, and data transmission errors. DigiLine changed everything, offering digital precision, loss-free data transfer, and simple calibration that drastically improved process control and efficiency.

Equipped with modern interfaces like Profibus-DP, Profinet, and EtherCAT, DigiLine set the stage for fully automated, fail-safe vacuum measurement, replacing the tangle of separate analog lines.

-

2001: Pfeiffer technology on the ISS

In 2001, Pfeiffer reached again new heights – 400 kilometers above Earth, to be exact. A specially designed compact turbopump joined the crew of the International Space Station (ISS), playing a key role in the study of plasma crystals. Later missions saw Pfeiffer pumps and gauges support weightless material experiments, helping create better materials for life back on Earth.

-

2010: Growing portfolio, infinite possibilities

With the acquisitions of Trinos in Göttingen, Germany, and Alcatel-Lucent's adixen vacuum technology unit in Annecy, France, Pfeiffer did not just grow – it transformed. Now offering everything from vacuum chambers to components, systems and leak detectors, the company created a comprehensive portfolio of high-quality vacuum solutions, nearly doubling its size.

-

2017: Expanding expertise – globally and technologically

With the acquisitions of ATC, Dreebit, and Nor-Cal Products in 2017, Pfeiffer welcomed another wave of cutting-edge innovation. From Micro-Flow air leak detectors to ion beam vacuum systems and precision components for the semiconductor industry, the portfolio became broader, deeper, and more future-ready than ever. The message was clear: when it comes to high and ultra-high vacuum, Pfeiffer is the go-to expert.

-

2021: A laser-sharp innovation in turbopump technology

Over 60 years after inventing the turbopump, Pfeiffer pushed the boundaries again – this time with laser light. In 2021, the company was granted a patent for its innovative Laser Balancing method, a high-precision technique that fine-tunes turbopump rotors without screws or grinding. Instead, a high-powered laser delicately evaporates material to achieve perfect balance.

The result? Quiet, extremely reliable, ultra-stable turbomolecular vacuum pumps, ideal for the most demanding high- and ultra-high vacuum applications.

-

2021: When service becomes effortless – Virtual Service Management

In September 2021, Pfeiffer launched its groundbreaking cloud-based service solution: Virtual Service Management (VSM). With just a few clicks, users can effortlessly organize vacuum equipment from any manufacturer, plan maintenance, and streamline service activities – all in one intuitive app or online in web-based version.

-

2021: Innovation, Silicon Valley style

December 2021 saw the grand opening of the Silicon Valley Innovation Center in San José. Here, the bright minds of the Pfeiffer experts collaborate directly with customers to tailor vacuum solutions for the high-tech demands of the semiconductor industry. With cutting-edge labs and rapid prototyping facilities, the center is a hub for turning bold ideas into real-world solutions.

-

2024: United under the Busch Group roof

In 2024, Pfeiffer became part of the Busch Group, creating a powerhouse of vacuum technology with over 8,000 experts worldwide. This merger combined the know-how of Busch in rough and medium vacuum with the technological leadership of Pfeiffer in high and ultra-high vacuum. The result? A global one-stop shop offering vacuum solutions for various industries, for Research & Development, semiconductor and analytics.

Covering applications from space tech to food packaging. Enabling technological progress and exploring the frontiers of knowledge across the globe.

-

2025: A clean sweep in semiconductor solutions

Pfeiffer Vacuum+Fab Solutions welcomed a powerful addition in 2025: the gas abatement systems from centrotherm clean solutions, a former Busch Group brand. These systems, essential for managing emissions in chip production, are now part of the Pfeiffer portfolio.

With vacuum and abatement solutions under one trusted brand, Pfeiffer offers end-to-end solutions for the semiconductor industry as well as for the production of MEMS, LEDs, solar cells or flat panel displays. Same high-quality technology – now delivered by one expert.

Busch Group locations

In all sectors of the industry. Locals near you. Around the globe.

- Sales companies

- Local representatives

- Production sites

Shape the vacuum world of the future

We welcome all talents, regardless of education, age, gender, or nationality.