3.7 Manipulators and mechanical feedthroughs

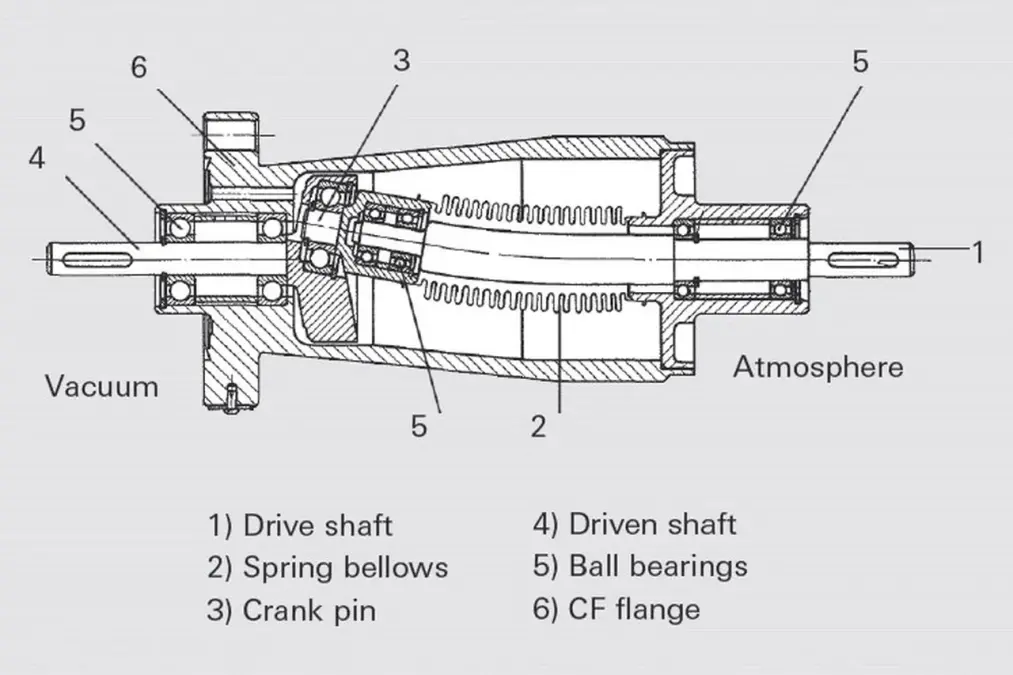

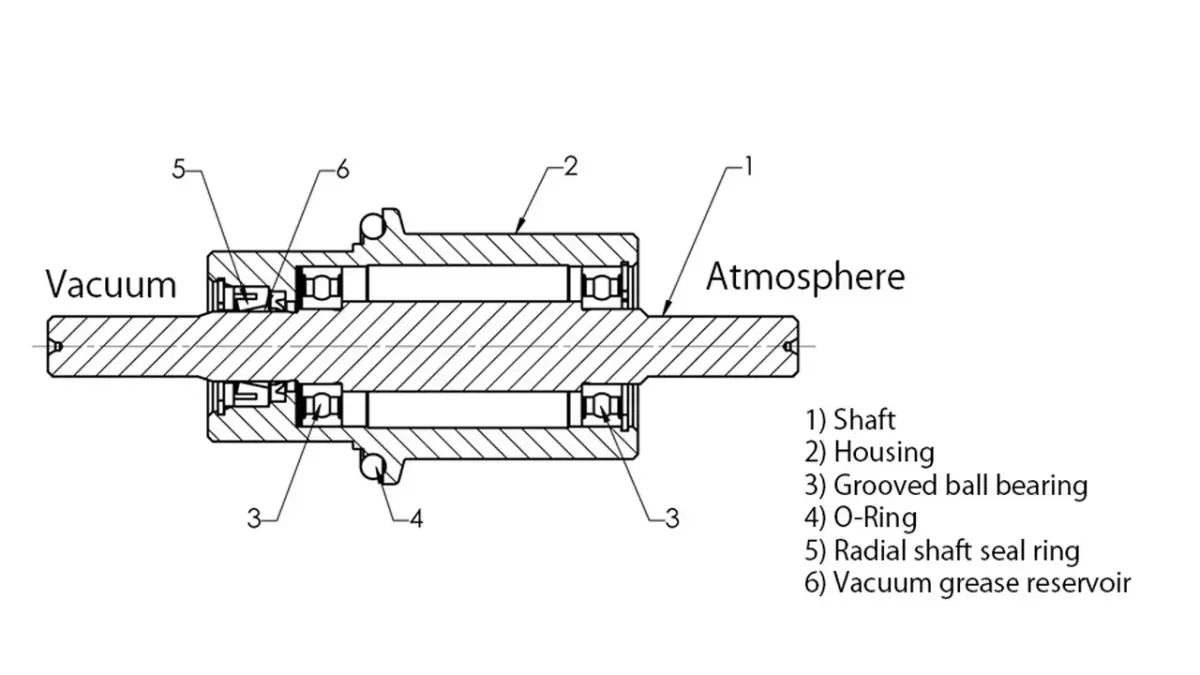

Many vacuum processes in research and industrial production require the movement of samples or components in the evacuated area. This can be linear position changes in the orientation of the three spatial axes and the revolution around the axis, as a single movement or as combinations of movement types among each other.Manipulators and mechanical feedthroughs allow translations and rotations in the vacuum, their drive is located on the atmospheric side and the movements are transferred in a vacuum-tight way. Several different action and transmission principles are used, which are in accordance with the respective and vacuum and application conditions. Metallic membrane and spring bellows, special elastomer seals, magnetically coupled systems or differentially pumped seals can be used as sealing elements.

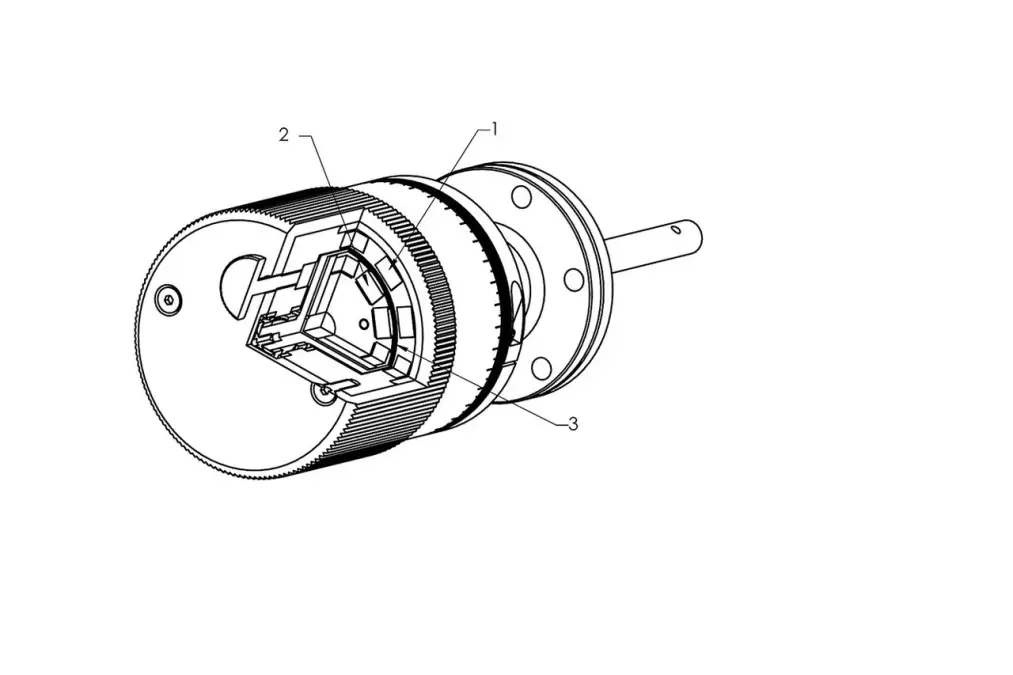

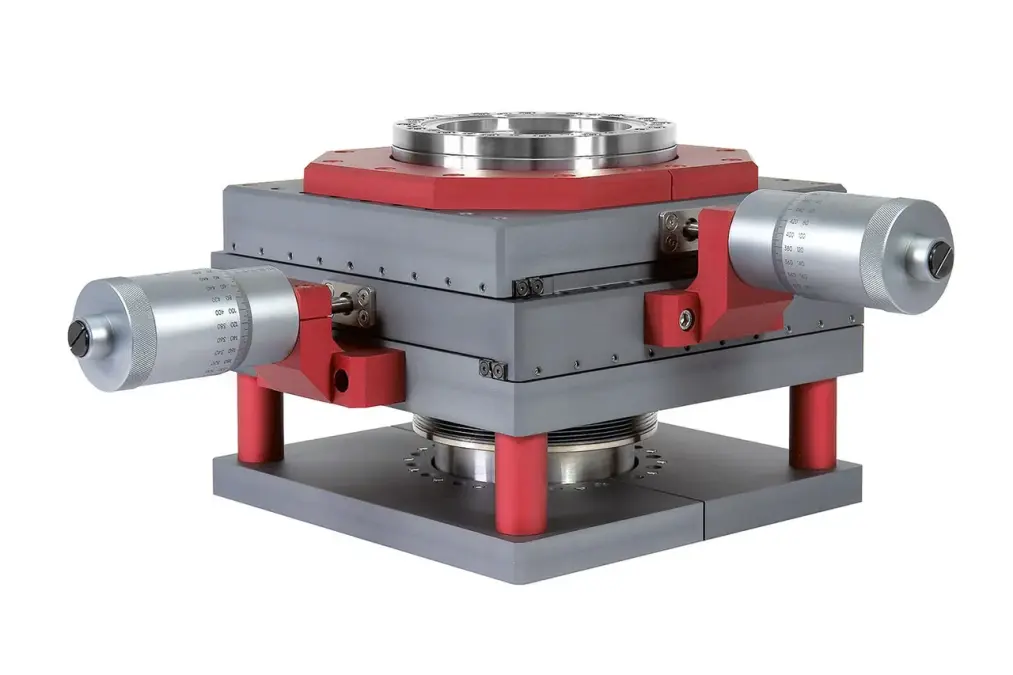

The designs with two open flange connections and an open passage are called manipulators, and components that have an actuator installed in a vacuum-tight flange are called mechanical feedthroughs. The latter are characterized by a compact design. Manipulators can be combined and extended among each other. In addition, mechanical feedthroughs can be attached to them, so that diverse types of movements transfer into the vacuum and with that provide solutions for various motion tasks. Additionally, other feedthroughs can be attached to the inlet flange, for example, for electricity or fluids and these can be guided by the manipulator directly to the application.

Especially with larger nominal diameters, the flanges of manipulators are under considerable forces due to the atmospheric pressure. So that the flanges are stable under vacuum, great emphasis must be placed on their inherent rigidity during the design of manipulators. The particular design challenge is to bring the highly precise transmission of movements in accordance with the external load and other loads by built-in components. The built-in components must be able to be baked out, in order to ensure the use even in the UHV range.