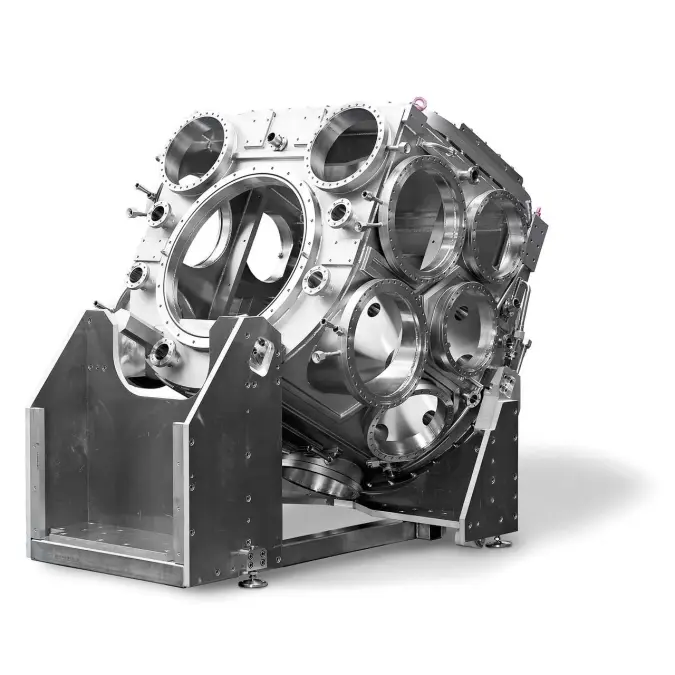

3.4 Vacuum chambers

The heart of a vacuum system is the vacuum chamber, which is tailored to specific application. It encloses the application and reliably separates it from the outside or protects the surrounding from the processes inside. Irrespective of whether a fine vacuum is required for drying processes, a medium or high vacuum for plasma processes or ultra-high vacuum for surface studies: – The vacuum chamber must always mechanically bear the pressure difference from the atmosphere.Vacuum vessel within the European Union are not subject to any specific guidelines upon which a design and calculation has be based on. They are not pressure equipment (Pressure Equipment Directive 2014/68/EU applies to components with an internal gauge pressure greater than 500 hPa) and they are not classified as machines according to the Machinery Directive 2006/42/EC. Nevertheless, they must be designed, calculated, manufactured in a safe and reliable way and tested prior to commissioning.

The calculation of wall thickness for cylindrical tubes, spherical bodies, flat floors or mold parts, such as dished ends can be done using the AD-2000 leaflets. The AD 2000 regulation was actually designed by the “pressure vessel working committee“ for the calculation of pressure vessels, but which also describes the load condition “external overpressure”. Here you will find, for example, equations for calculating the required wall thicknesses that include the “elastic buckling” or “plastic deformation” of cylindrical tubes.