3.6 Valves

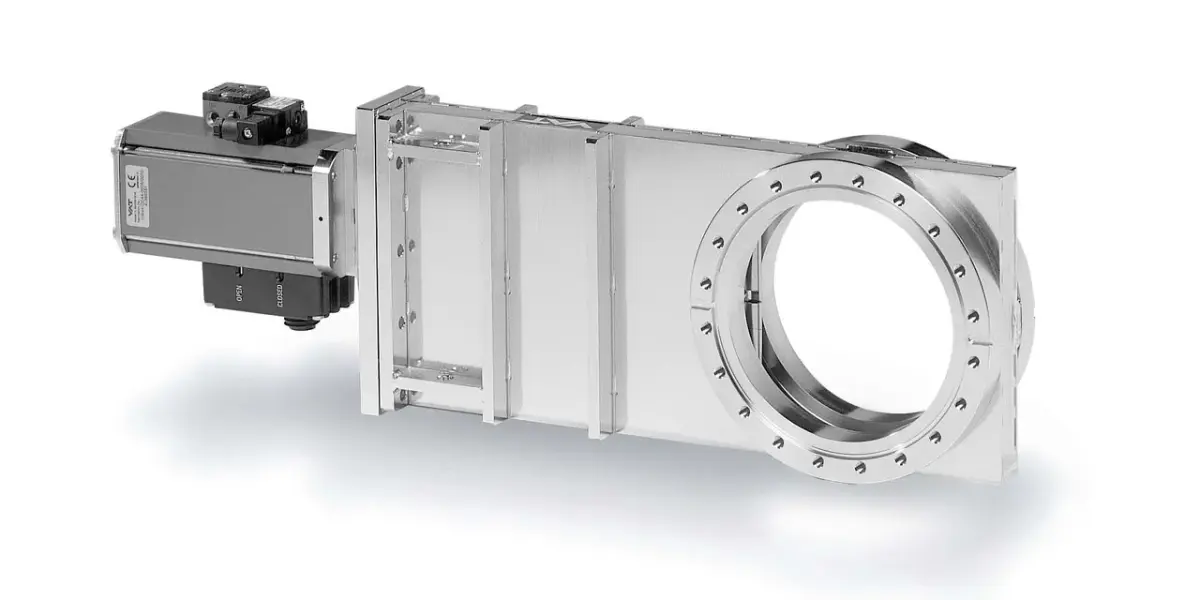

Valves in vacuum systems can also be subject to special requirements, in addition to the general technical requirements for shut-off elements that are typical of vacuum technology and have to be taken into consideration in engineering the products.The minimum displaced ultimate pressure and the high flow resistance of components in the molecular flow range must be taken into consideration in configuring and selecting vacuum valves. In addition, minimum leakage rates are required for the valve housing and valve seat. Vacuum-side lubricants for the moving parts in the valves must be suitable for the required pressure and temperature ranges, or avoided entirely, if possible, in high or ultra high vacuum. Minimum dead volumes and high conductivities are important, particularly in the molecular flow range.

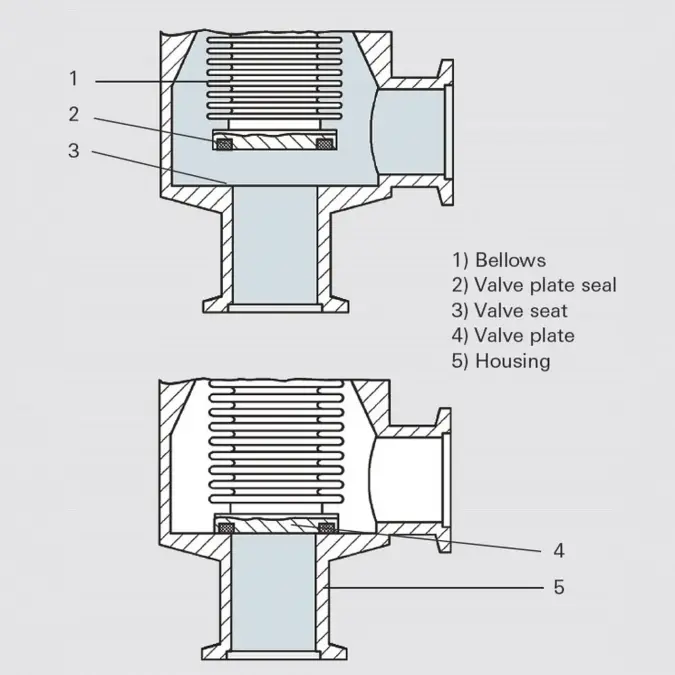

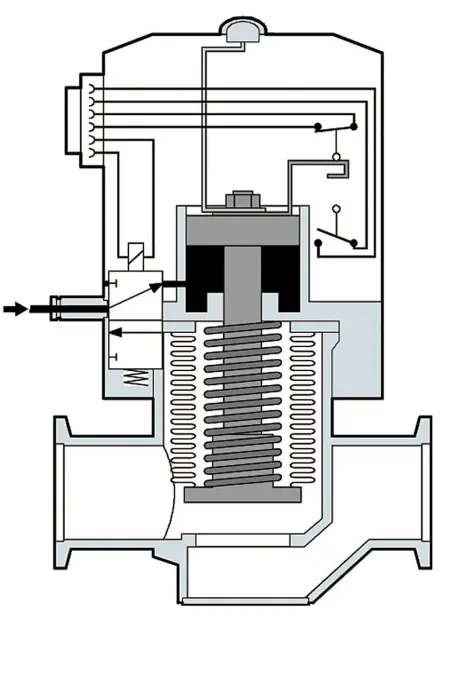

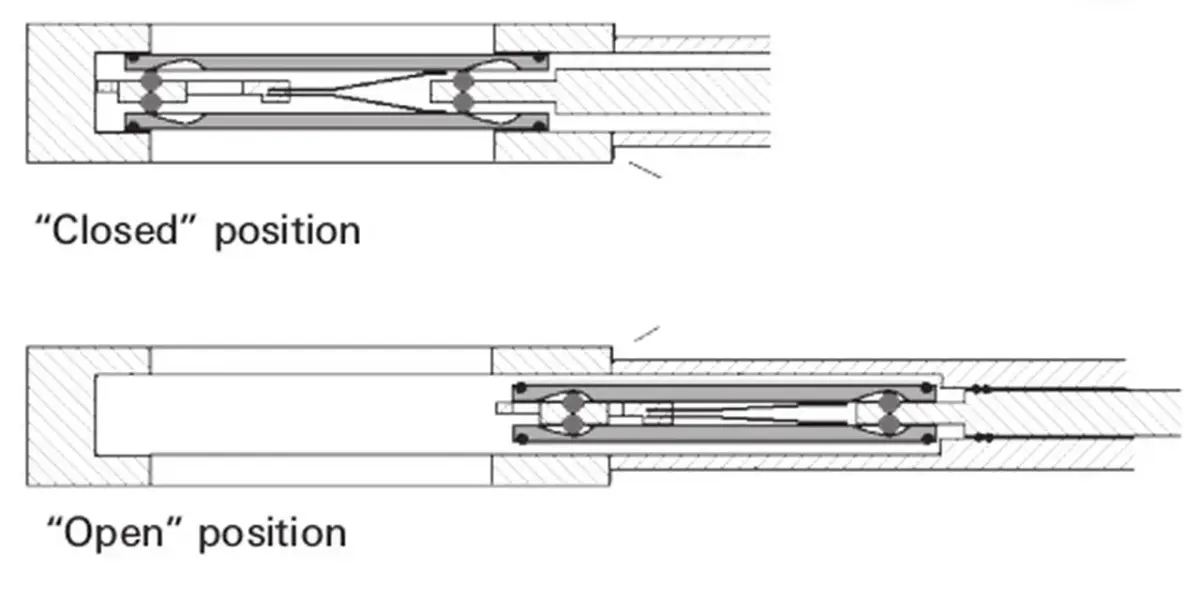

The feedthrough for mechanical actuation elements must be designed in such a manner as to satisfy requirements with respect to tightness, as well as the pressure and temperature ranges. Depending on the quality, elastomer sealed feedthroughs (e.g. shaft seals) can be used for lower vacuum requirements in the pressure range greater than 1 · 10-4 hPa. While membran or spring bellows are used for pressure ranges of less than 1 · 10-4 hPa. In addition, valves sealed with a metal bellows can be baked out if appropriately engineered. Valves with elastomer sealed housing, plate or flangs are used for pressures of up to 1 · 10-8 hPa. The installation is generally done in a way that the atmospheric pressure is on the valve plate, in closed position, and thus increases the closing force.

All-metal valves, in which all seals are made of metal, are suitable for UHV applications and higher bake-out temperatures, however they usually require higher closing forces to seal. Soft metals (copper or special alloys) are used as sealing materials. In addition to higher closing forces, shorter seal service life must also be expected.

There are a variety of different types of valves for the various applications in the field of vacuum technology; these valves are named on the basis of their design or function.