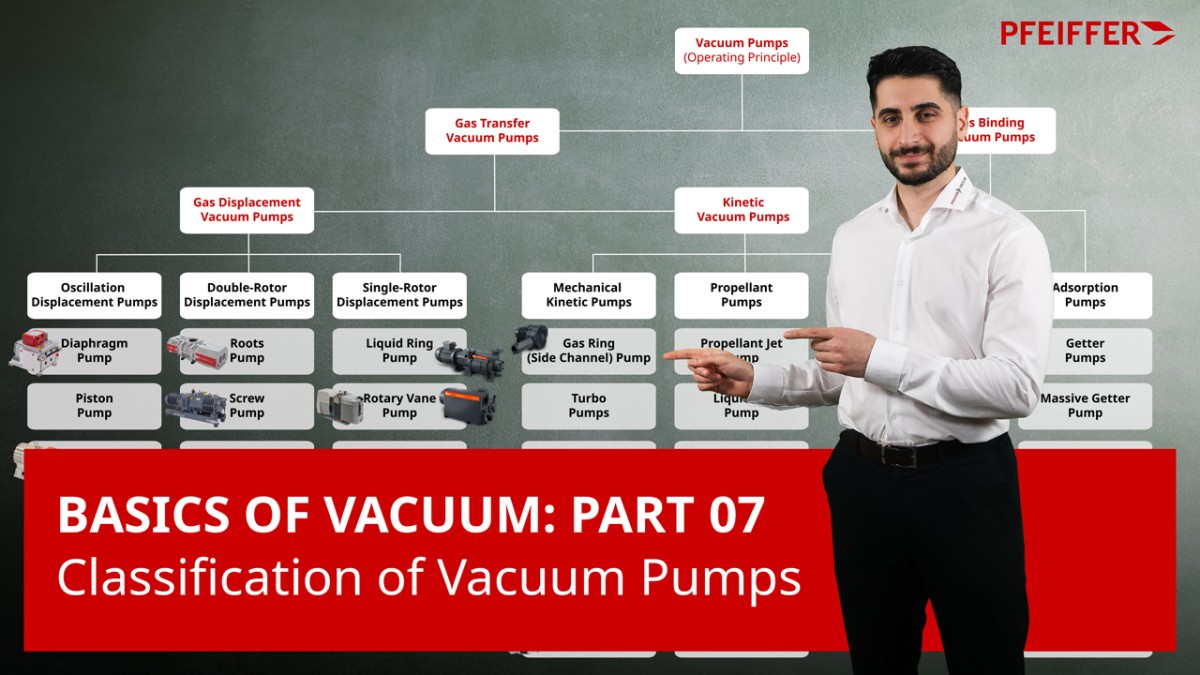

4.1 Vacuum pumps – working principles and properties

4.1.1 Classification of vacuum pumps

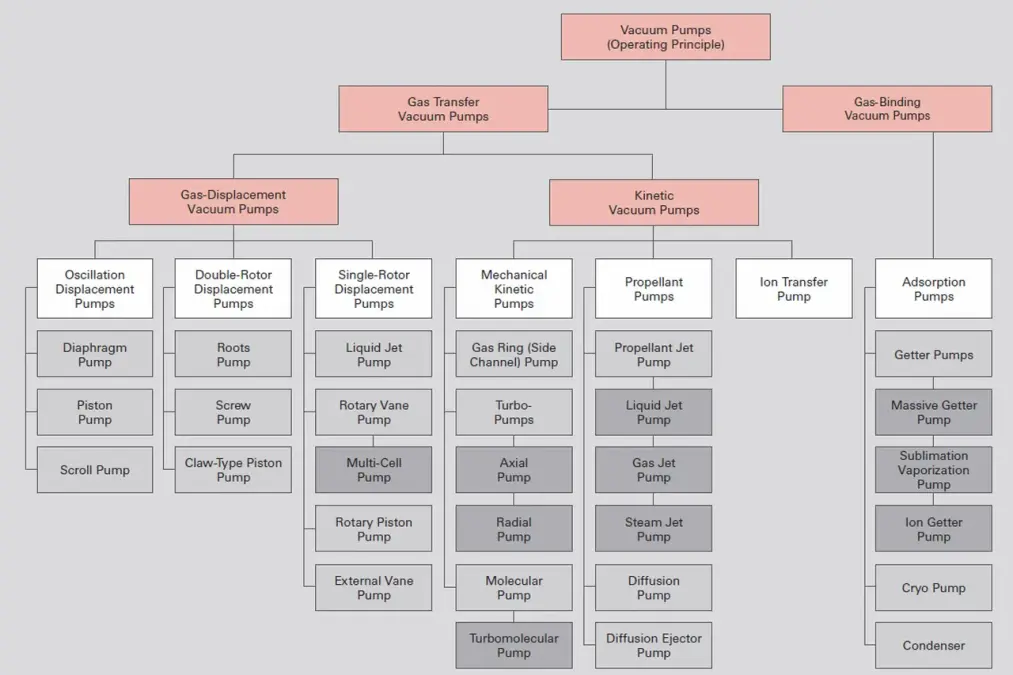

Vacuum pumps are categorized as gas transfer pumps and gas binding or capture pumps. While gas-displacement vacuum pumps can be used without limitation, gas-binding vacuum pumps have a limited gas absorption capacity and must be regenerated at certain process-dependent intervals.Gas-displacement pumps, which are also referred to as gas transfer pumps, are classified either as positive displacement pumps or kinetic vacuum pumps. Positive displacement pumps displace gas from sealed areas to the atmosphere or to a downstream pump stage. Kinetic pumps displace gas by accelerating it in the pumping direction, either via a mechanical drive system or through a directed vapor stream that is condensed at the end of the pumping section. Gas-binding vacuum pumps either bind the gas to an especially active substrate through gettering or condense the gas at a suitable temperature. Chemisorption is performed technically by a pump type known as getter pumps which constantly generate pure getter surfaces through vaporization and/or sublimation or sputtering. If the gas particles to be bound are ionized in an ion getter pump before interacting with a getter surface, they can at the same time clean the getter surface by sputtering and be buried by sputtered material. Non evaporable getters (NEG) consist of highly reactive alloys, mainly of zirconium or titanium, and have a very large specific surface. Gases can penetrate into deeper layers of the getter material through micropores and be bound there into stable chemical compounds.