Vapors

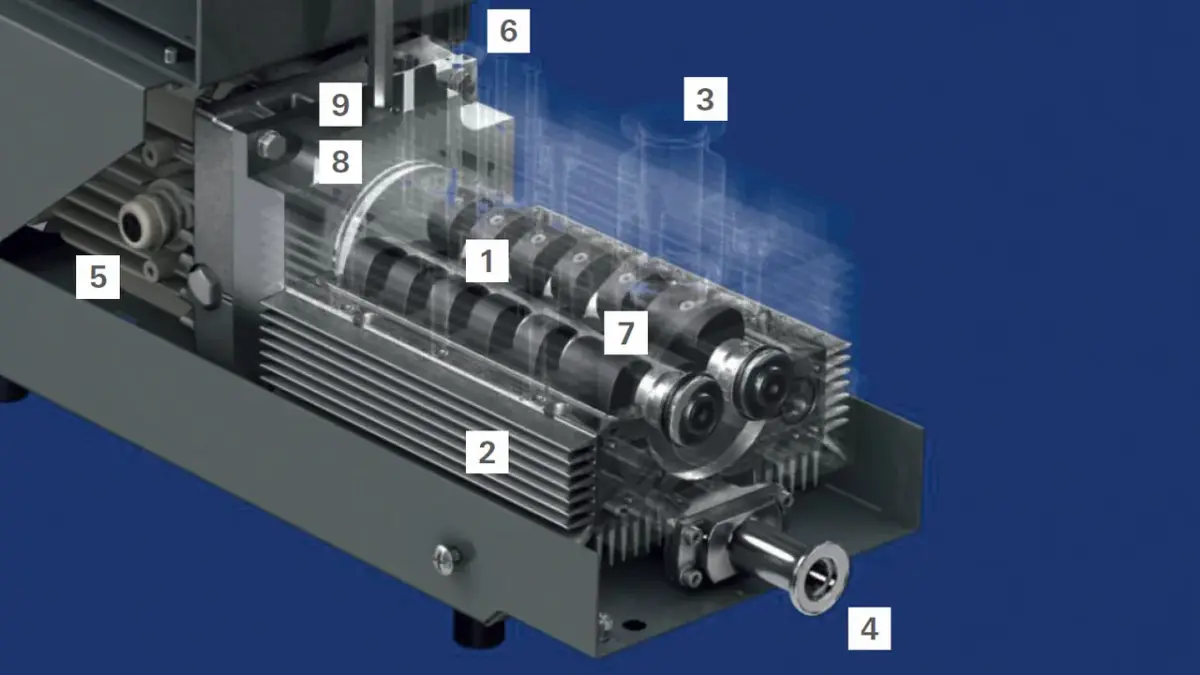

Without additional measures, there is a danger of condensation inside the pump with oil-free pumps due to their comparatively low operating temperature. Similarly to rotary vane pumps, multi-stage roots pumps are fitted with a gas ballast valve to increase the water vapor tolerance and the water vapor capacity of the pump. Condensate formation inside the pump increases the ultimate pressure, results in corrosion and at worst to total failure of the pump.

ACP pumps can convey media with a moisture content of up to 5 % without gas ballast. With the standard pump gas ballast, the water vapor tolerance is 10 hPa and the water vapor capacity 100 g · h

-1. With an increased gas ballast throughput in special pump versions (CV, Condensable Vapors) water vapor tolerances of about 100 hPa and water vapor capacities of 700 to 1,000 g · h

-1 can be attained, depending on the ambient temperature.

As for rotary vane pumps: before evacuating the vapors, the pump must have warmed up for at least half an hour with gas ballast. The higher temperature of the pump block reduces condensation. Additional measures to reduce condensation include obtaining the lowest possible outlet pressure and separate removal of condensates. Backpressure at the outlet must be prevented with a vertical exhaust gas line. If an extraction system is available, the outlet should be connected to it.

Dust and particles

The multi-stage roots pumps in the ACP series can, at worst, become blocked and fail completely as a result of uncontrolled immissions of large particles. For this reason filters are fitted on the intake side in dust-laden processes or, for instance, in glass-making to protect from breakage.

Corrosive gases

Pumps in the ACP series are not suitable for pumping down large quantities of corrosive gases. Multi-stage roots pumps are available for this purpose for corrosive gas processes in the semiconductor, solar and coating industry (

see Chapter 4.6). However, ACP series pumps can be used to handle at least traces of corrosive gases. In this case, versions with inert gas purge are used in which the bearings are protected with an inert gas curtain and process gases are diluted by introducing inert gas in one of the pump stages.

Leak rate

Their high tightness makes multi-stage roots pumps the perfect solution for long-term use and gas circuits with expensive gases (

4He,

3He, isotope-marked gases).

Light gases and high vacuum

Multi-stage roots pumps have an outlet valve to prevent humidity and oxygen from diffusing back to the suction chamber which in corrosive gas applications would cause chemical reactions to occur in the pump. This valve must be opened periodically (e. g. through gas ballast) in applications where a vacuum requires to be generated in order to prevent light gases from collecting and diffusing back.

Even a slight vacuum at the exhaust or the use of gas ballast is enough to displace even a continuous gas throughput of helium, such as in an evaporator cryostat, with almost the same performance data as nitrogen or air.

In applications where the use of carrier gas is prohibited (such as in closed loop applications), there must be a vacuum at the pump outlet.