4.9 Turbomolecular pumps

4.9.1. Design / Operating principle

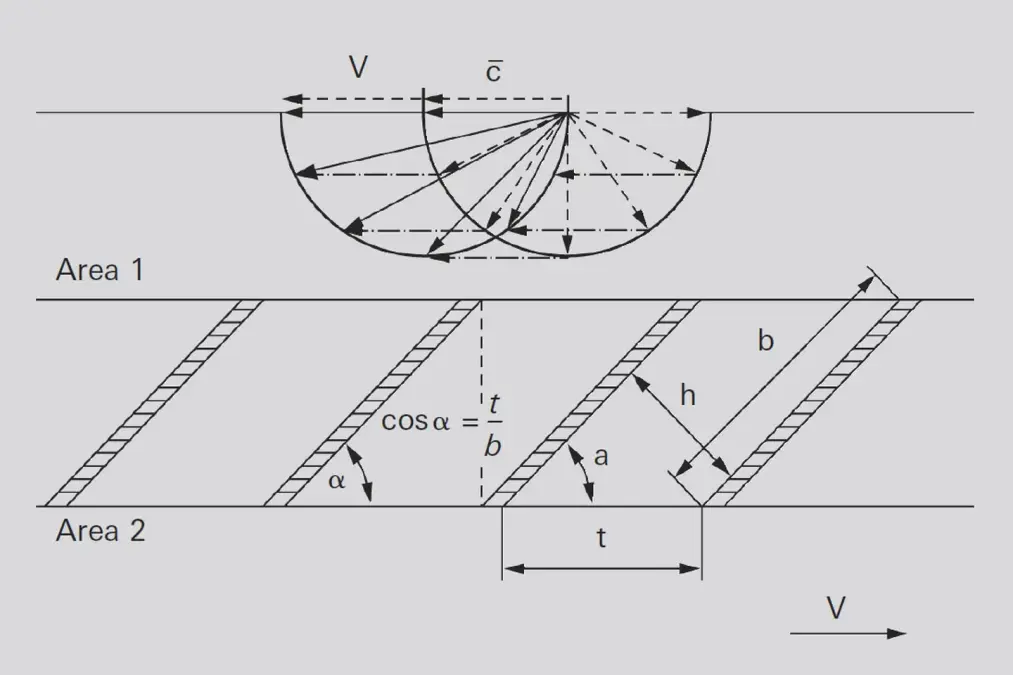

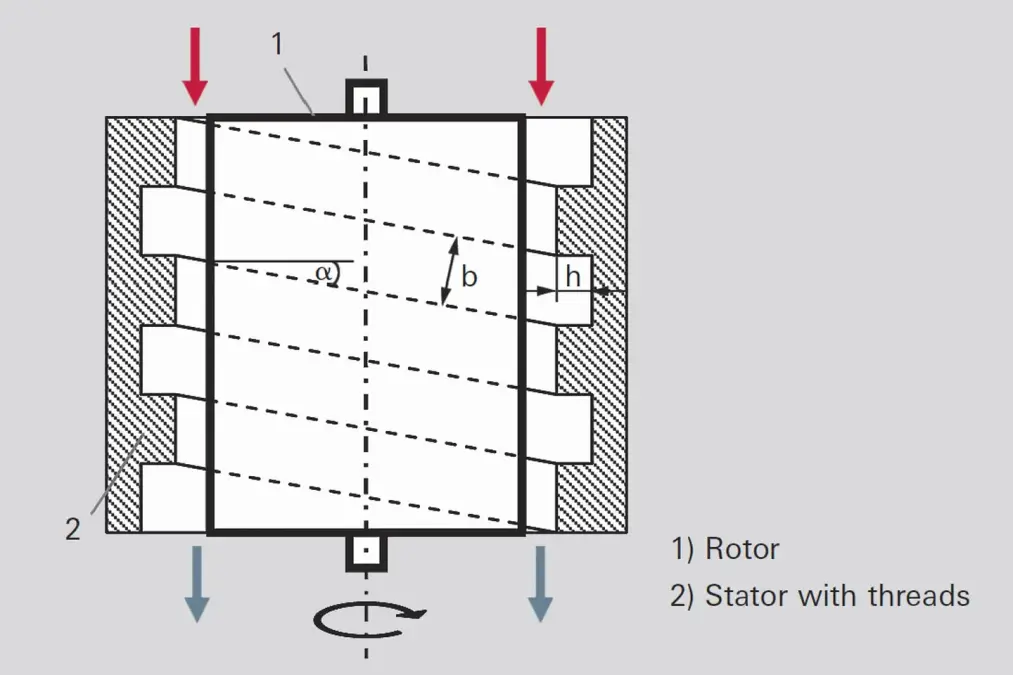

The turbomolecular pump was developed and patented at Pfeiffer Vacuum in 1958 by Dr. W. Becker. Turbomolecular pumps belong to the category of kinetic vacuum pumps. Their design is similar to that of a turbine. A multi-stage, turbine-like rotor with bladed disks rotates in a housing. The blades of a turbine or a compressor are referred to collectively as the blading. Interposed mirror-invertedly between the rotor disks are bladed stator disks having similar geometries.Bearings

Mounting the shaft of a turbopump rotor by means of two ball bearings requires arrangement of both bearings on the fore-vacuum side due to the lubricants in the bearings. This results in a unilateral (cantilever) support of the rotor with its large mass.Hybrid bearing support offers advantages in this regard with respect to rotor dynamics. Hybrid bearing designates the use of two bearing concepts in one single pump. In this case, an oil-lubricated ball bearing is mounted on the end of the shaft on the fore-vacuum side, and the high vacuum side is equipped with a maintenance-free and wear-free permanent magnetic bearing that centers the rotor radially. The oil for lubricating the fore-vacuum side bearing is contained in an operating fluid reservoir. A small dry safety bearing is arranged within the magnetic bearing stator. During normal operation, a journal rotates freely within this bearing. In the event of strong radial shocks, the safety bearing stabilizes the rotor and rotates only briefly. If the rotor is out of balance, the bearings on both ends of the shaft will generate significantly lower bearing-stressing vibration forces than in the case of a floating bearing. The magnetic bearing on the high vacuum side is totally insensitive to vibration. Only very small vibration forces are transferred to the housing as a result. Moreover, this eliminates the need for the larger of the two bearings in a cantilever concept, whose size limits rotational speed.

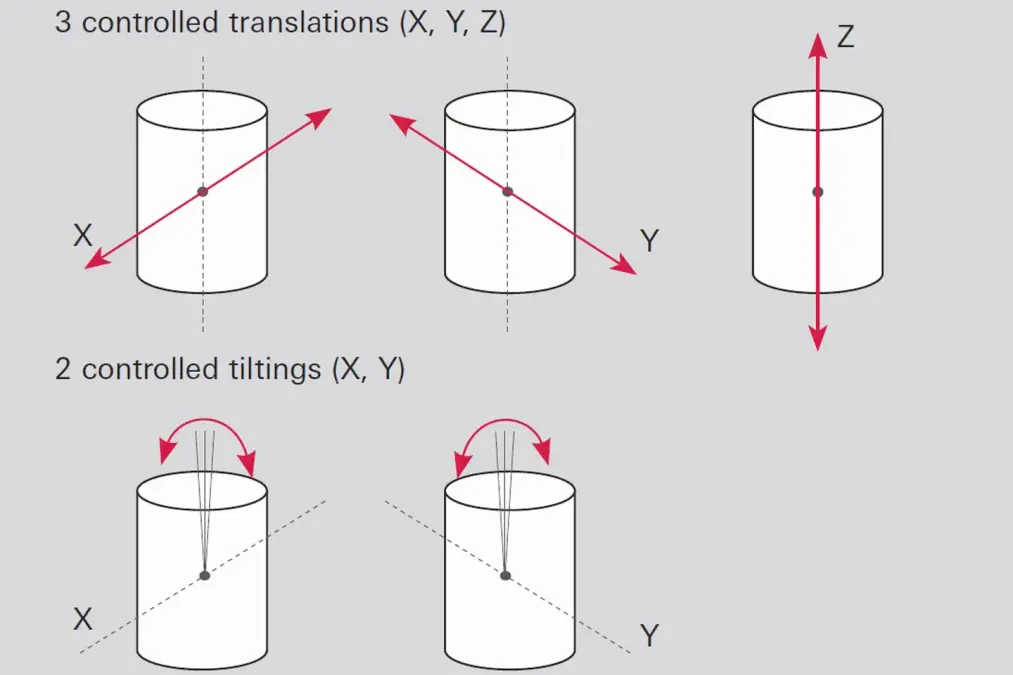

Large pumps from a flange diameter of 100 mm alternatively use bearings known as 5-axis magnetic bearings [24]. The rotor is levitated through digital electronic control via distance sensors and electromagnets. The degrees of freedom of the movement of a turborotor are continuously monitored and readjusted in real time. The absence of mechanical contact between the rotor and housing keeps the vibration generated by the pump low. The rotor revolves around its own axis of inertia. Any imbalance due to one-sided coating or erosion (such as in plasma etching) is counteracted within broad limits.

In addition to the absence of oil on the backing-vacuum side, freedom from wear and maintenance is another advantage. In the event of a power failure, the magnetic bearings are supplied with electricity through the rotational energy of the pump. This enables power failures to be easily bridged for several minutes. Should the power failure be of longer duration, the rotor will safely come to a stop at a very low speed through the use of an integrated safety bearing. During system malfunctions, the safety bearing shuts down the rotor to avoid any damage to the pump.