The role of hydrogen in energy transition and emission

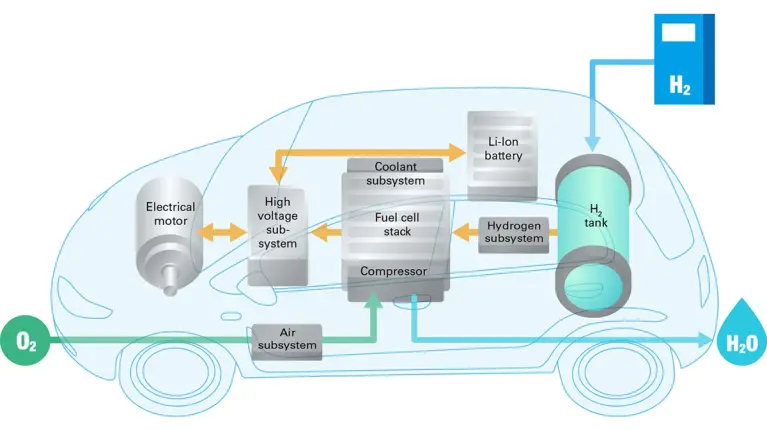

Hydrogen is an energy carrier which can be stored, transported and used. Hydrogen-based technology can play an important role in decarbonizing various industrial sectors, as well as in zero emission mobility with long driving ranges and short refueling times.Chemical reaction of hydrogen in a fuel cell produces only water, electricity and heat.

Fuel cells can play an important role in a large range of applications - mobility, industrial, residential and portable.