From Rough to Ultra-High Vacuum Applications

Serving all vacuum levels with innovative technology.

Vacuum technology for your application

-

Helium leak detection

Precise helium leak detection ensures the integrity of vacuum systems for safe and efficient operation.

Learn more

-

Generation of ultra-high vacuum (UHV)

UHV enables groundbreaking research and production in ultra-clean, particle-free environments.

Learn more

-

Container Closure Integrity Testing (CCIT)

Vacuum-based CCIT ensures sterile, leak-free packaging for pharmaceutical safety and quality.

Learn more

-

Residual gas analysis (RGA)

RGA in vacuum systems identifies contaminants, ensuring process cleanliness and equipment protection.

Learn more

-

Mass spectrometry

Vacuum enables accurate ion transport for precise mass analysis in advanced spectrometry techniques.

Learn more

-

Heat treatment/Vacuum furnaces

Vacuum heat treatment enables uniform material transformation at low process temperatures, ensuring consistent quality and surface finish.

Learn more

-

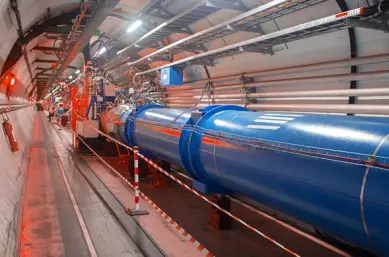

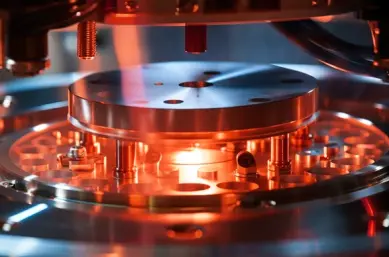

Accelerators

Vacuum in accelerators ensures particle beam stability for high-precision research and imaging.

Learn more

-

Leak testing in automotive, aeronautics and refrigeration

Vacuum leak detection ensures safety and efficiency in high-performance automotive and aerospace systems.

Learn more

-

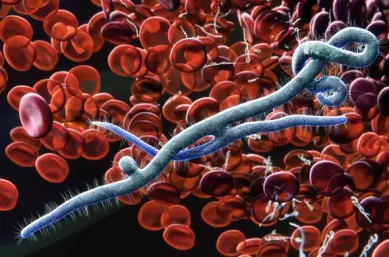

Electron microscopy

Vacuum allows electron flow without scattering, delivering high-resolution imaging of even the tiniest structures.

Learn more

-

Lithium-ion batteries

Vacuum processes improve battery performance, cleanliness, and safety during cell manufacturing.

Learn more

-

Thin film coating

Vacuum ensures uniform thin films for high-performance optical, electronic, and decorative layers.

Learn more

-

Solar cell manufacturing

High vacuum ensures carbon-free environments for efficient, high-quality solar cell production.

Learn more

-

Hydrogen fuel cells

Vacuum technology ensures safe, leak-free hydrogen storage and efficient fuel cell operation.

Learn more

-

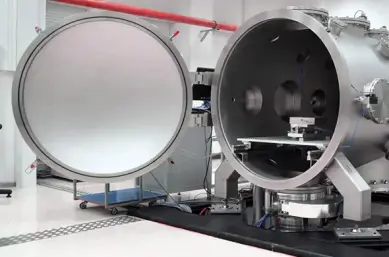

Space simulation

Vacuum chambers simulate outer space for testing satellite and spacecraft performance reliably.

Learn more

-

EUV lithography

Vacuum is critical for precise, particle-free EUV lithography in semiconductor production.

Learn more

-

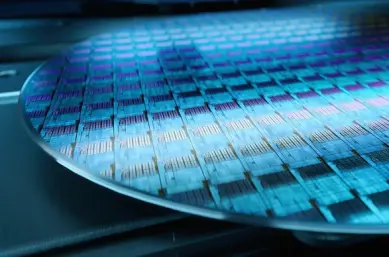

Semiconductor etching and cleaning

Vacuum enables precise etching and cleaning for nanoscale semiconductor manufacturing.

Learn more

-

Airborne molecular contamination (AMC)

One of the main sources of wafer defectivity causing yield losses in semiconductor fabs.

Learn more -

Thin film deposition

Vacuum in thin film deposition for semiconductors minimizes contamination, ensures uniformity, and allows precise control over the deposition process.

Learn more -

-

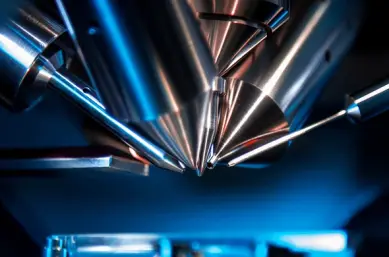

Ion source, beamline and end station

The production of a semiconductor component is a highly intricate process including multiple stages carried out in a vacuum environment.

Learn more -

CD-SEM

A growing number of production steps and extremely small device dimensions make wafer inspection and metrology more crucial than ever.

Learn more -

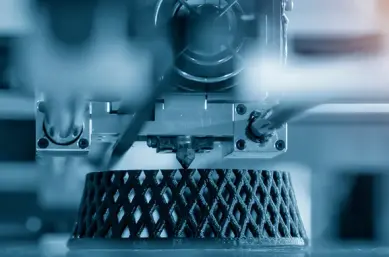

3D printing

Vacuum prevents oxidation, improves material quality, and boosts energy efficiency by allowing higher energy densities during melting.

Learn more -

Sterilization

Sterilization is a process to kill different kinds of microorganisms such as fungi, bacteria, viruses and spores.

Learn more