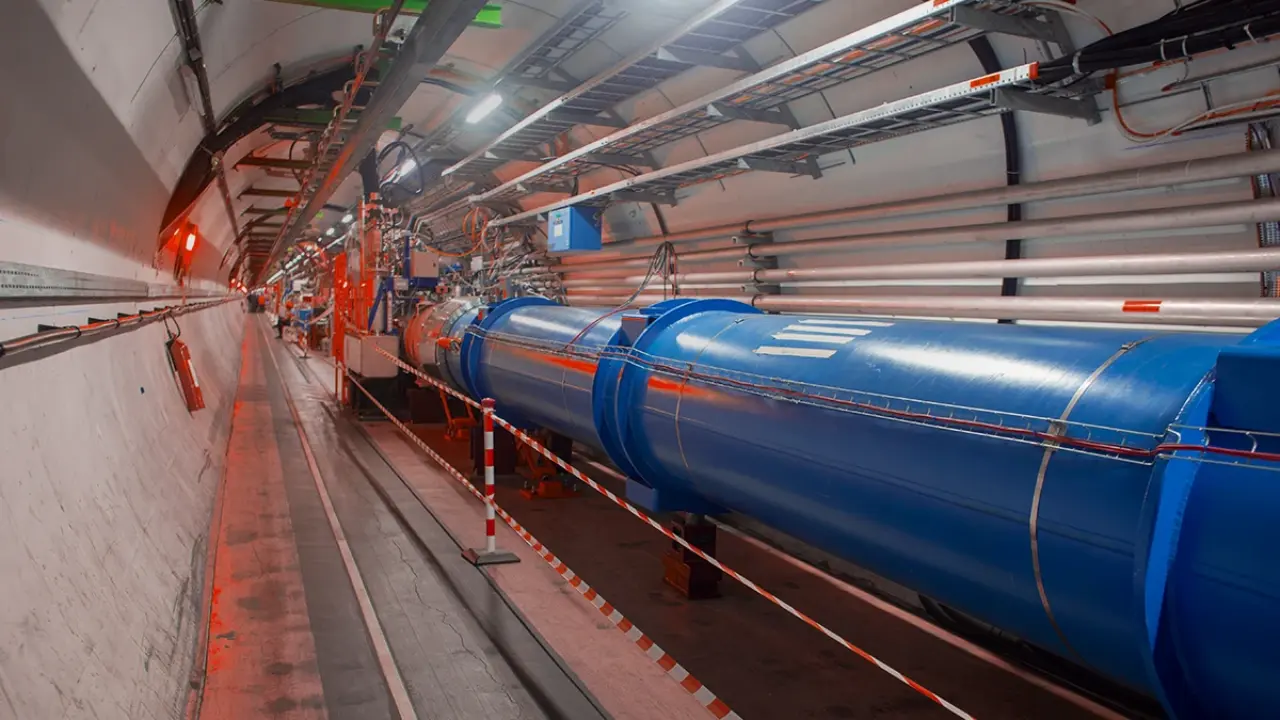

Vacuum requirements in accelerator applications

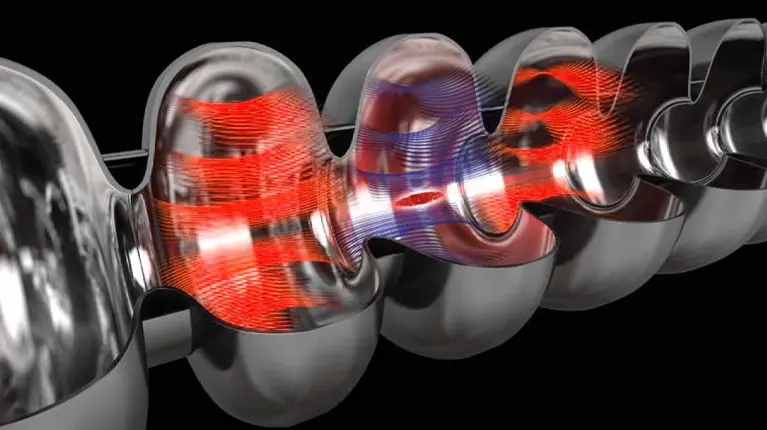

Accelerators place extraordinary demands on vacuum systems: ultra-high vacuum levels, resistance to ionizing radiation, compatibility with cryogenics, and 24/7 operational stability. These requirements vary across application areas – from high-energy particle physics to precision-focused medical treatment – and shape the way vacuum components are designed, engineered, and deployed.