Powering research across disciplines

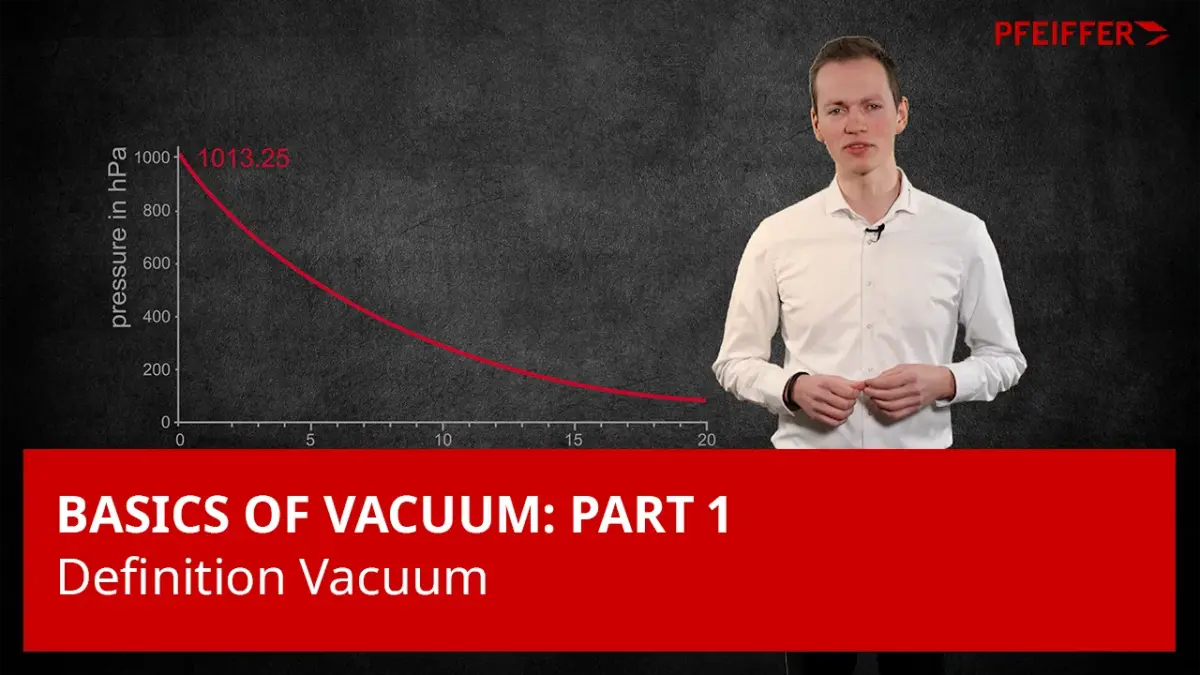

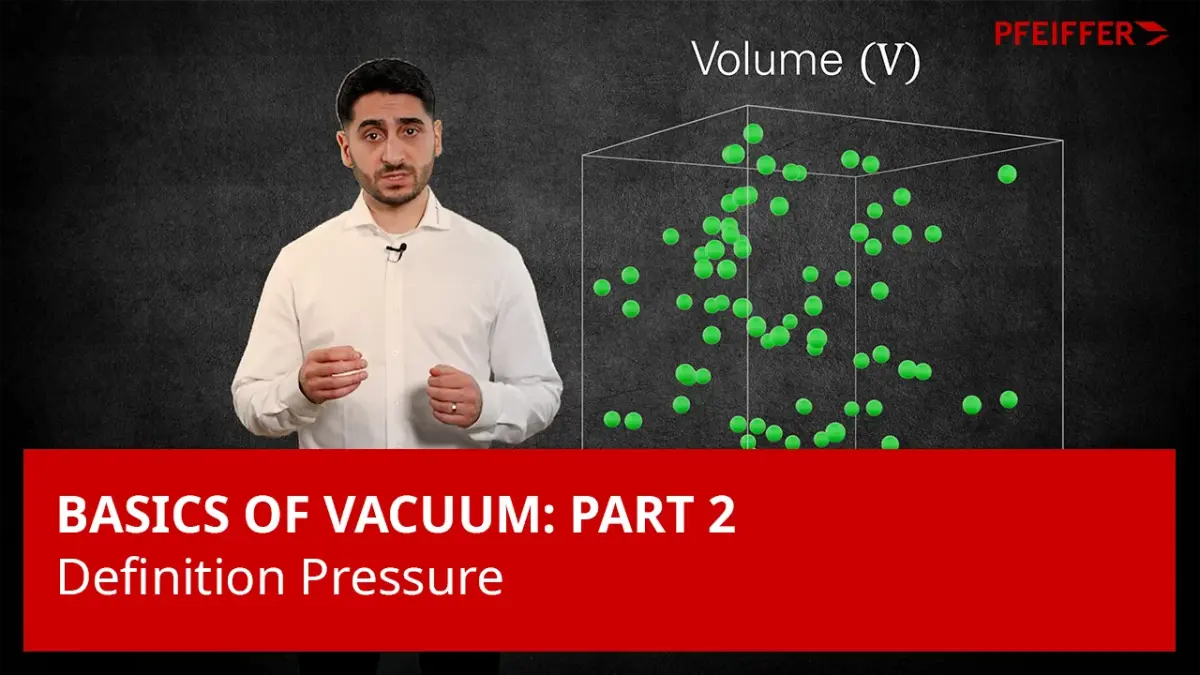

Whether you are developing the next generation of semiconductors, exploring quantum materials, or running high-energy physics experiments, different pressure levels address specific research needs:- Rough to medium vacuum supports common lab processes such as glove box, Schlenk lines, and drying.

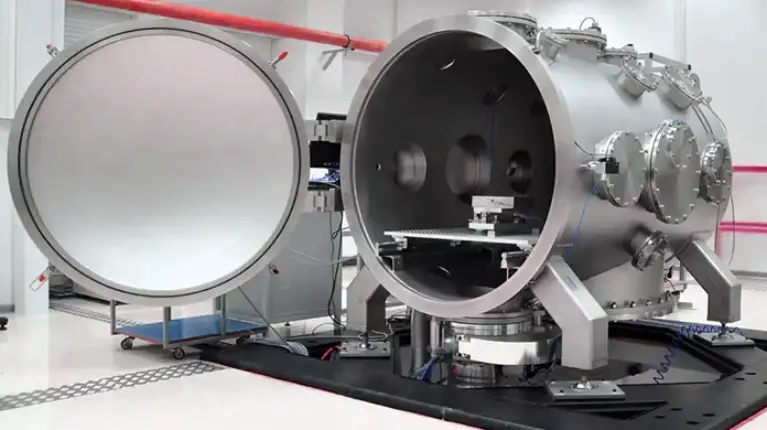

- High to ultra-high vacuum (UHV) is essential for surface science, plasma physics, and cryogenic research.

- UHV enables precision in particle accelerators, surface analysis, and high-energy physics.

But vacuum is more than just selecting the right pump. The system must also be properly connected, precisely measured, and continuously analyzed. From instrumentation and sensor integration to residual gas analysis and leak detection, Pfeiffer provides complete vacuum solutions that ensure your setup performs reliably and efficiently.