Vacuum for Analysis With Scientific Instruments

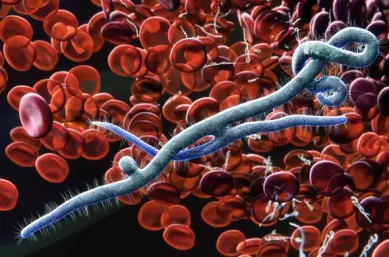

The scientific instruments market includes all applications that require vacuum for analysis. Over the past century, the number of different analysis methods has grown significantly. In addition to R&D, new fields such as environmental analysis and production control have emerged.

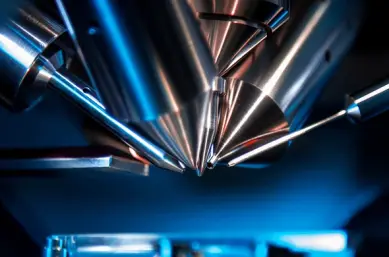

Techniques like mass spectrometry, electron microscopy or x-ray are commonly used to gather detailed information about samples. These applications often require customized vacuum solutions, which Pfeiffer can develop in close collaboration with customers to ensure optimal performance.