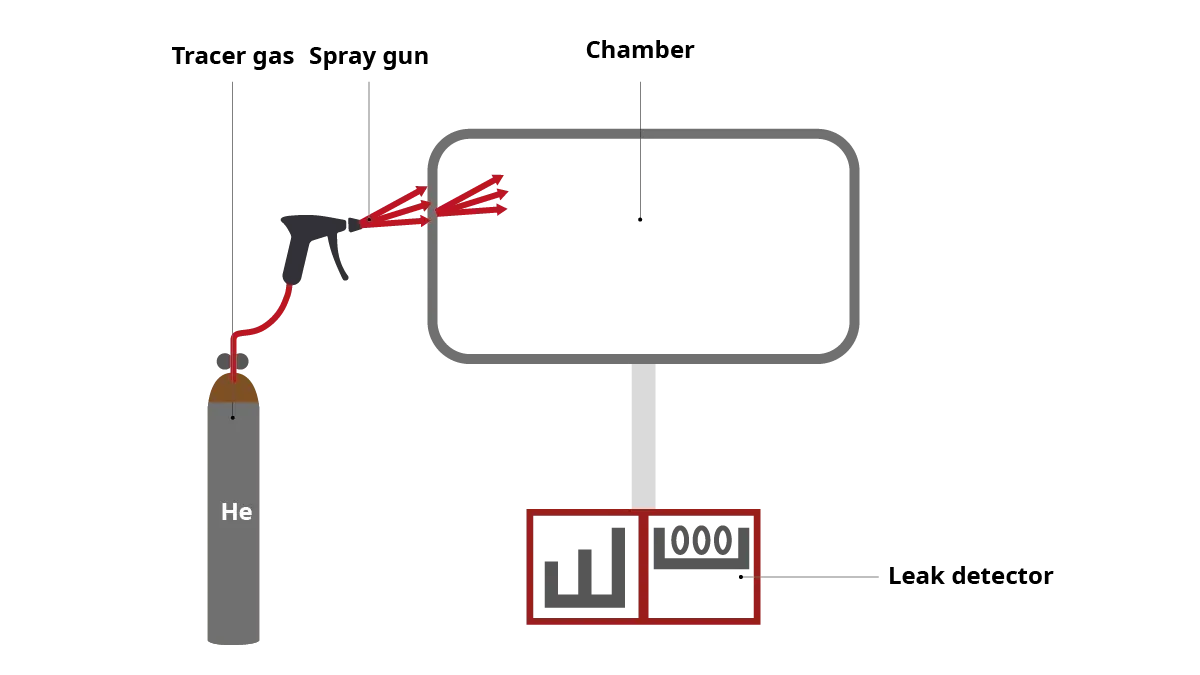

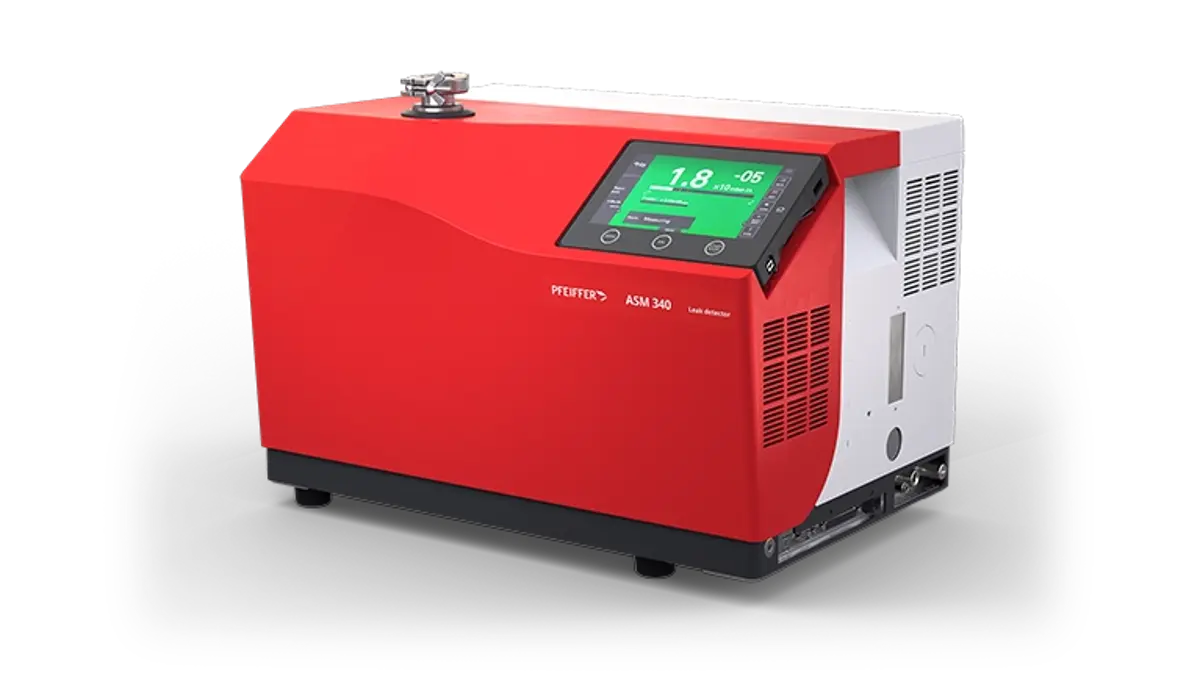

Helium spraying for accurate leak localization

In large vacuum systems, even small leaks can compromise performance, contaminate processes, or delay operations. A pressure rise or decay test often indicates that a leak exists – the next step is to detect the location quickly and reliably.That is where helium spraying becomes essential. This detection method is highly effective across a wide pressure range and supports qualitative testing.