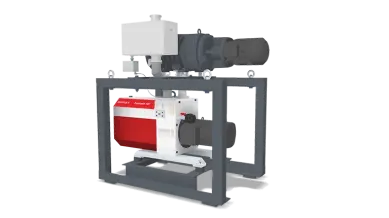

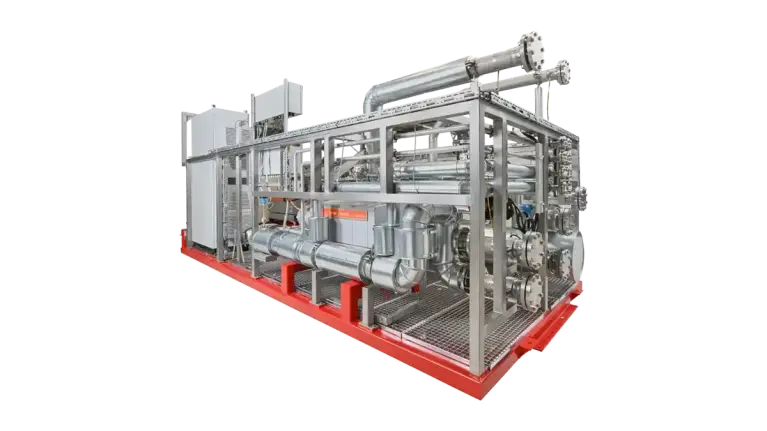

Suitable vacuum pump units for every application

In many applications, a single vacuum pump cannot reach the required vacuum level in time. This applies when processing large quantities of gas or when a particularly high vacuum level of ≤ 10-3 hPa (mbar) is necessary. Not every vacuum pump can operate from atmospheric pressure, so an additional backing pump – also known as roughing pump – is required. Together with the vacuum pump, the backing pump forms a complete vacuum pump unit capable of handling differential pressure efficiently.The most frequently used vacuum pump units are our turbomolecular vacuum pump units and our vacuum booster pump units.