Reliable vacuum booster pump units with high pumping speeds

- Reliable

- High performance

- Flexible

Please update your browser. It looks like you are using an old version of the Microsoft Edge browser. To get the best experience with the Pfeiffer website, please update your browser.

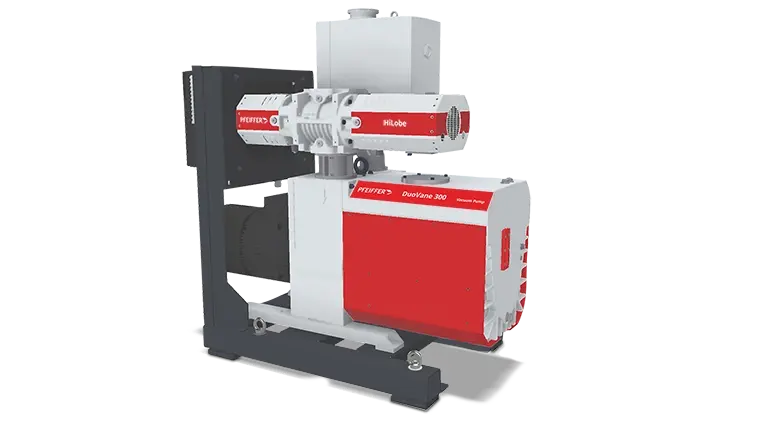

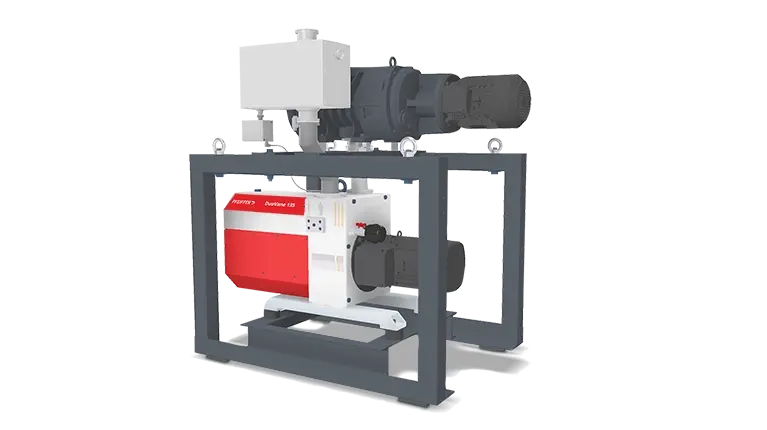

Vacuum booster pump units

Our COMBI vacuum booster pump units are preconfigured, highly efficient systems. They consist of a HiLobe or a PANDA vacuum booster and a matching backing pump like a R5 or a DuoVane rotary vane vacuum pump or a COBRA screw vacuum pump. Additionally, integrated interfaces like Profinet (Ethernet protocol) and components such as pipes or valves are included. These features ensure excellent performance resulting in rapid evacuation times and consistent vacuum levels. Customized solutions are also available to suit specific process requirements. For example, additional stages with further vacuum boosters can be integrated into the unit to achieve lower ultimate pressure and reduce power consumption.

Ideal for standard applications like drying and degassing, our vacuum booster pump units also excel in processes requiring high reliability, such as vacuum packaging, metallurgy, vacuum drying, or leak detection systems. In general, they are an excellent choice for use in confined spaces.

Thanks to the integrated HiLobe vacuum booster with its highly efficient interior permanent magnet motor (IPM), this version of our vacuum booster pump units enables fast pump-down times. The motor meets IE4 and IE5 standards, ensuring low operating costs that are further enhanced by efficient air or water cooling. To enable installations in confined spaces, only small and medium HiLobe versions are used in the vacuum booster pump units. With flexible mounting positions, they can be positioned vertically or horizontally. Our COMBI vacuum booster pump units come in standard configurations that can be tailored to specific applications, with a range of optional accessories available. For example, control cabinets provide protected housing for electronic equipment and control units, facilitating condition monitoring and reliable process management of the vacuum booster pump units via the ProfiNet interface (Ethernet protocol).

Depending on whether the backing pump is dry or oil-lubricated, the entire vacuum pump unit is classified accordingly.

The COMBI RH vacuum booster pump units ensure high pumping speeds and fast evacuation times, making them ideal for load lock applications. They combine dry backing pumps, typically COBRA screw vacuum pumps, with HiLobe vacuum boosters.

Equipped with oil-lubricated single-stage rotary vane vacuum pumps like the R5, COMBI RU vacuum booster pump units deliver gas-independent pumping speeds thanks to highly durable, fiber-reinforced epoxy resin vanes that ensure stable performance regardless of the gas type. These robust vanes offer chemical resistance and require minimal maintenance. Typical applications include helium leak detection or metallurgy.

The COMBI RD vacuum pump units combine a HiLobe with a two-stage rotary vane vacuum pump, such as the DuoVane. The standard model is equipped with shaft seals, while an alternative configuration features the DuoVane with magnetic coupling. When combined with a hermetically sealed HiLobe, this results in a permanently sealed vacuum pump unit that prevents leakage and contamination, ensuring reliable and clean vacuum generation. Our COMBI RD vacuum pump units are particularly suitable for pumping noble gases and achieving low ultimate pressures. They are ideal as backing pumps for high vacuum pumps like turbomolecular vacuum pumps, since the two-stage rotary vane vacuum pump achieves a lower ultimate pressure than single-stage models. These vacuum booster pump units are frequently used in applications like metallurgy, vacuum coating or R&D.

Equipped with a bypass valve, the integrated PANDA vacuum booster is reliably protected against overloading or overheating. Therefore, it can optimally be used for high differential pressures.

PANDA vacuum boosters operate contact-free without any operating fluids in the process chamber, ensuring minimal maintenance requirements. Their exceptional volumetric efficiency allows them to convey a large volume of pumped medium per rotation and achieve high flow rates. Optionally, PANDA vacuum boosters are available with variable speed drives, resulting in low energy consumption and reduced operating costs.

COMBI BNV vacuum booster pump units combine backing pumps, typically screw vacuum pumps from the COBRA series, with PANDA vacuum boosters. This combination delivers high pumping speeds at low ultimate pressures, ensuring short pump-down time. Typical applications are metallurgy, packaging or vacuum drying.

COMBI BRV vacuum pump units are equipped with R5 single-stage rotary vane vacuum pumps. The R5 series features extremely durable high-performance vanes of fiber-reinforced epoxy resin that ensure a long service life and continuous operation. This makes the vacuum booster pump unit ideal for rapid evacuation of load lock chambers, as well as applications like electron beam welding and surface treatment.