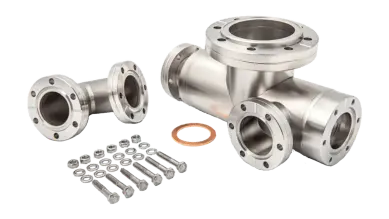

Standard vacuum chambers

Our product range of standard vacuum chambers offers a quickly available and cost-efficient alternative to custom-manufactured vacuum chambers. You can combine various standardized basic bodies with freely selectable chamber outlets to create a vacuum solution tailored to your application.The standard vacuum chambers are designed for ambient pressure usage up to 1 · 10-7 hPa (mbar).