Vacuum Feedthroughs

Create effective connections and improve the performance and quality of your industrial applications.

Technology for efficient industrial solutions

Customization for specific requirements

Vacuum feedthroughs can be tailored to meet your exact needs by selecting from various designs for temperature, pressure, and material compatibility.

Adaptability to extreme conditions

Our feedthroughs are designed to function effectively in both high and low temperature and pressure environments.

Material and design flexibility

Customers can choose from a variety of materials and design options to ensure the feedthroughs meet their specific application requirements.

Tailor-made solutions

Our team of skilled engineers and technicians works closely with you to gain a detailed understanding of your needs. This collaboration allows us to design and develop feedthroughs that are precisely engineered for your vacuum systems, ensuring optimal performance and reliability. With this tailored approach, we deliver feedthroughs that not only meet your expectations but exceed them.

Why vacuum feedthroughs from Pfeiffer?

With our extensive expertise and commitment to customer satisfaction, we are the ideal partner for all your vacuum needs.

FAQ

Why are feedthroughs important?

Vacuum feedthroughs play an essential role in vacuum technology, ensuring a secure and leak-tight connection between the internal and external parts of a vacuum system. They allow elements such as electrical cables, cooling water pipes, and mechanical components to pass through without compromising the vacuum. These components are critical for applications requiring precise pressure and environmental control, enabling efficient system operation and minimizing production errors.

What types of feedthroughs are available?

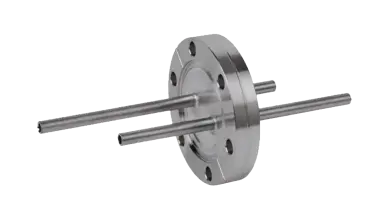

Power vacuum feedthroughs

Robust ceramic-to-metal feedthroughs have electrical ratings for operation, with one side in dry atmosphere while the opposite end is fitted in stable vacuum. Applications include ultra-high vacuum systems with CF flanges or high vacuum systems with NW flanges. Materials include high alumina ceramic insulators, OFHC® copper and nickel conductors, and 304 stainless steel flanges.

High voltage ceramic break insulators

Vacuum insulators (breaks and isolators) electronically isolate one component in your vacuum system from another. Maximum voltage for insulators is 3-15KV, depending on size. Our ceramic insulators are UHV compatible.

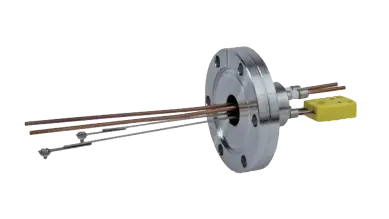

Thermocouple vacuum feedthroughs

Thermocouple feedthroughs carry instrumentation signals while providing electrical isolation and hermetic sealing. Insulators are made of high-purity, high-strength, low-loss alumina ceramic, and feature -20°C to 150°C elastomer seals.

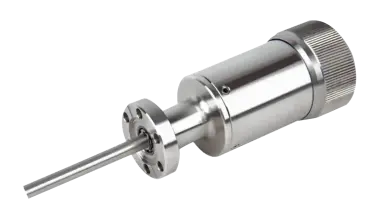

Instrumentation vacuum feedthroughs

Our 8 pin, 2 amp instrumentation feedthroughs transmit signal voltages and currents. Process control in surface analysis, electron microscopy and electron beam evaporation are typical applications. Multi-Pin, BNC coaxial, and MHV coaxial feedthroughs are available.

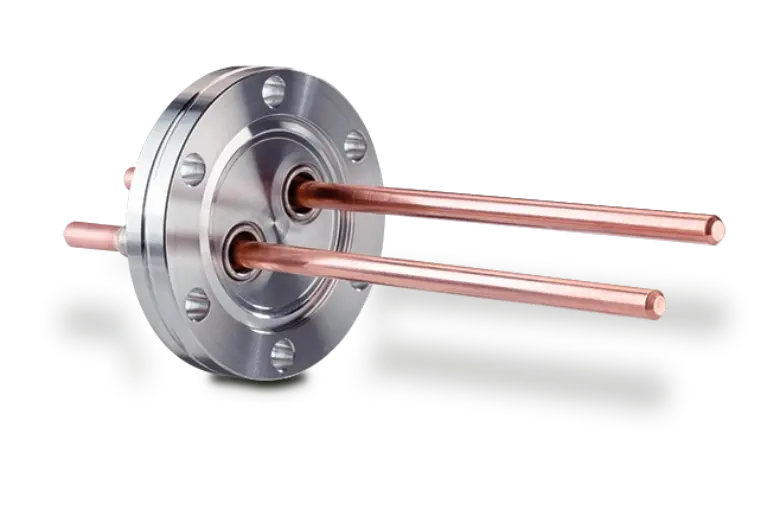

Liquid / Gas vacuum feedthroughs

Single and dual tube feedthroughs reduce condensation and ice buildup on the atmosphere side of the feedthrough and the mounting flange interface. Liquid / Gas feedthroughs are available without fittings or terminated with industry standard Swagelok® or Cajon® VCR tube fittings.

LN2 vacuum feedthroughs

Liquid nitrogen feedthroughs are constructed with dual and coaxial tube geometries to reduce condensation and ice buildup on the atmosphere side of the feedthrough around the mounting flange interface, protecting the seal’s integrity. Tubing is .25- and .375-inch OD with CF or NW flanges.

For which applications are electric and water-cooled feedthroughs used?

We manufacture both custom and standard vacuum feedthroughs designed for medium, high, and ultra-high vacuum applications. The performance of each feedthrough depends on its design and materials, ensuring optimal functionality for specific requirements. Frequent applications of our vacuum feedthroughs include:

- Semiconductor industry

- Research laboratories

- Energy and aerospace

- Life and health sciences