Devices with digital signal output

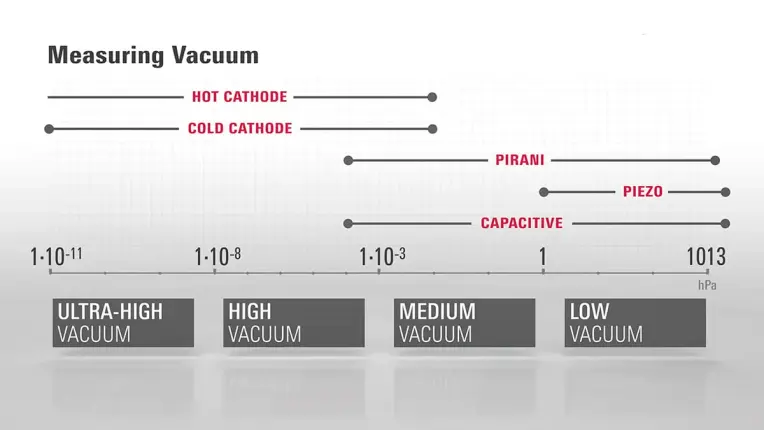

The DigiLine transmitters are designed for industrial and research applications requiring easy-to-install and reliable total pressure measurement. The gauges cover a wide vacuum range using Piezo, Pirani, capacitive, hot cathode, and cold cathode sensors. Each transmitter has an RS-485 interface, allowing up to 16 measuring points to be connected to a controller.Options for connectivity include Profibus-DP, Profinet, and EtherCAT interfaces, or an additional analog output with two switching points and an LCD display.

- Fail-safe communication with a PC or a PLC

- M12 connectors and IP54 protection for reliable operation in harsh environments

- Modern interfaces (industrial Ethernet and fieldbuses)