Types of multi-stage Roots vacuum pumps from Pfeiffer

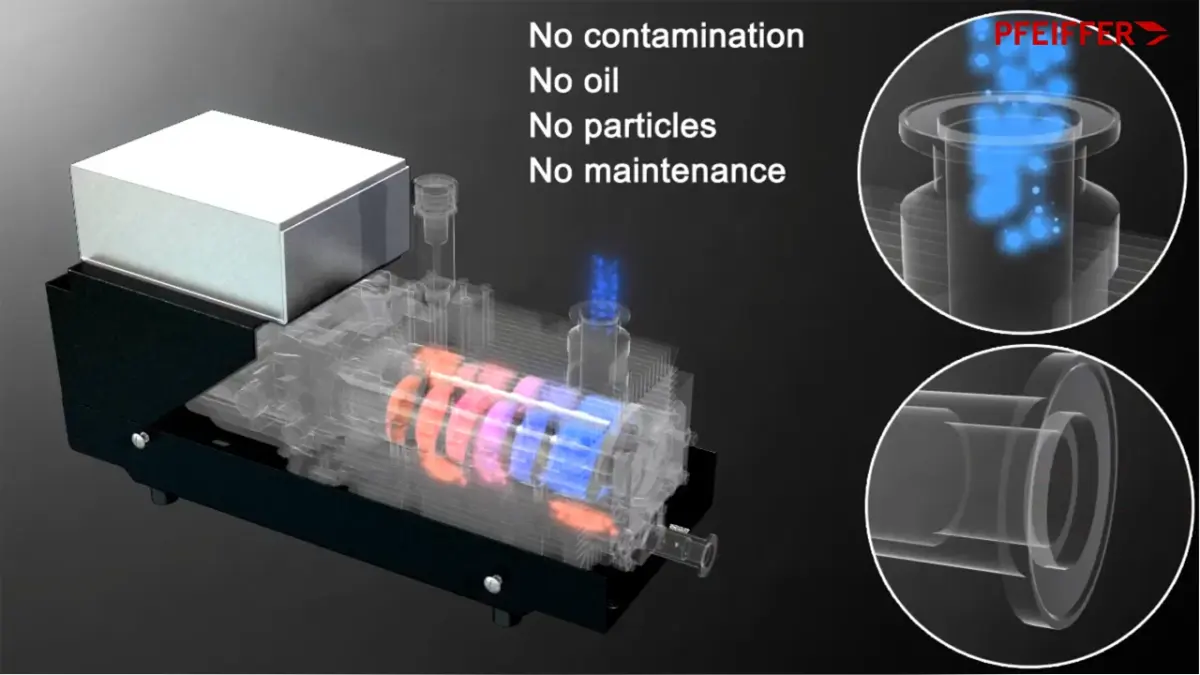

Multi-stage Roots vacuum pumps achieve low ultimate pressures up to 10-4 hPa (mbar). Their contact-free operation eliminates the need for lubrication, ensuring oil- and particle-free vacuum generation that is ideal for clean and dry vacuum processes such as in semiconductor manufacturing, vacuum coating or the chemical and pharmaceutical industries. Thanks to their robust design, these vacuum pumps offer a long service life with minimal maintenance requirements. Selected versions come with advanced protective coating materials that enhance gas compatibility in corrosive environments, making them suitable for harsh processes and high-value gas management applications, such as polysilicon etch or chemical vapor deposition (CVD).Our multi-stage Roots vacuum pumps comply with international standards, including CE, UL/CSA, and SEMI S2 certifications.