Types of vacuum boosters from Pfeiffer

Our HiLobe series vacuum boosters deliver an outstandingly broad range of pumping speeds – from 520 to 13,600 m3/h – setting a new standard in the market.They are available with three different cooling options: convection, active air (forced convection), or water cooling. Convection is a passive cooling method using natural air circulation and ambient temperature, whereas active air (forced convection) cooling actively directs airflow to the components that need cooling during operation.

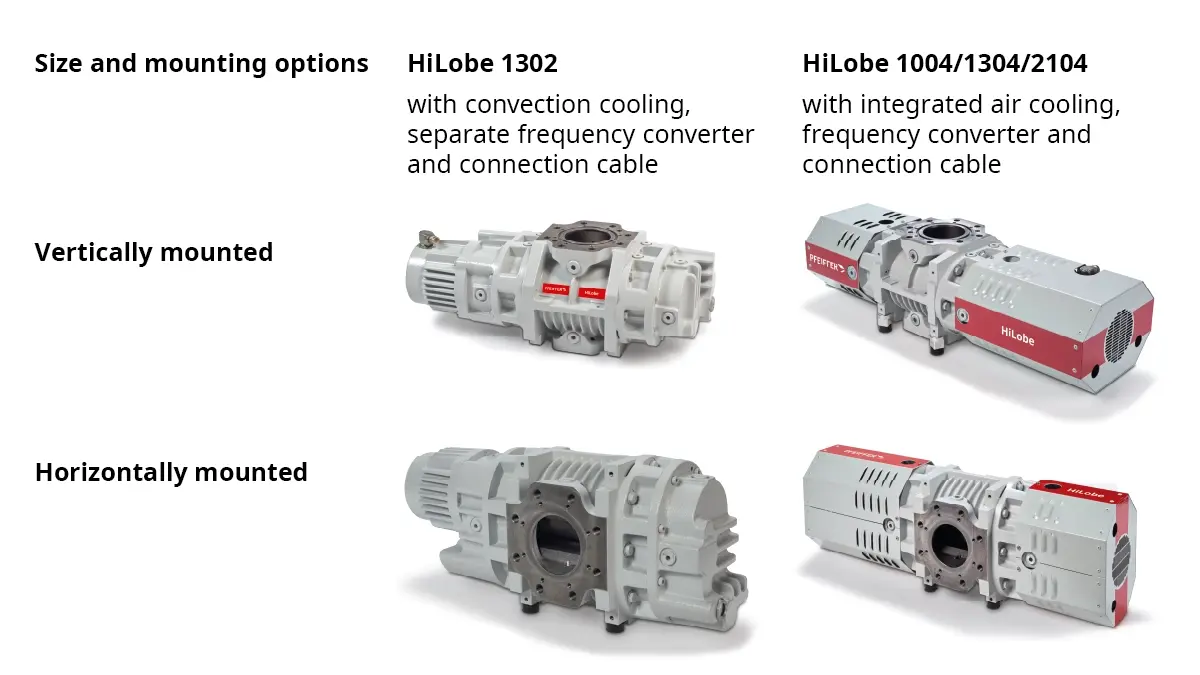

In addition to the standard vertical installation, the HiLobe vacuum boosters can also be installed horizontally. This flexibility allows for seamless integration into nearly any system, helping to reduce installation costs.

Model | Nominal pumping speed | Cooling type |

|---|---|---|

HiLobe 1002 | up to 1,300 m3/h | convection |

HiLobe 1004 | up to 1,300 m3/h | active air (forced convection) |

HiLobe 1302 | up to 2,100 m3/h | convection |

HiLobe 1304 | up to 2,100 m3/h | active air (forced convection) |

HiLobe 2104 | up to 2,100 m3/h | active air (forced convection) |

HiLobe 2703 | up to 2,700 m3/h | water |

HiLobe 2704 | up to 2,700 m3/h | active air (forced convection) |

HiLobe 4503 | up to 4,500 m3/h | water |

HiLobe 4504 | up to 4,500 m3/h | active air (forced convection) |

HiLobe 6203 | up to 6,200 m3/h | water |

HiLobe 6204 | up to 6,200 m3/h | active air (forced convection) |

HiLobe 8103 | up to 8,100 m3/h | water |

HiLobe 8104 | up to 8,100 m3/h | active air (forced convection) |

HiLobe 11003 | up to 11,000 m3/h | water |

HiLobe 11004 | up to 11,000 m3/h | active air (forced convection) |

HiLobe 14003 | up to 13,600 m3/h | water |

HiLobe 14004 | up to 13,600 m3/h | active air (forced convection) |