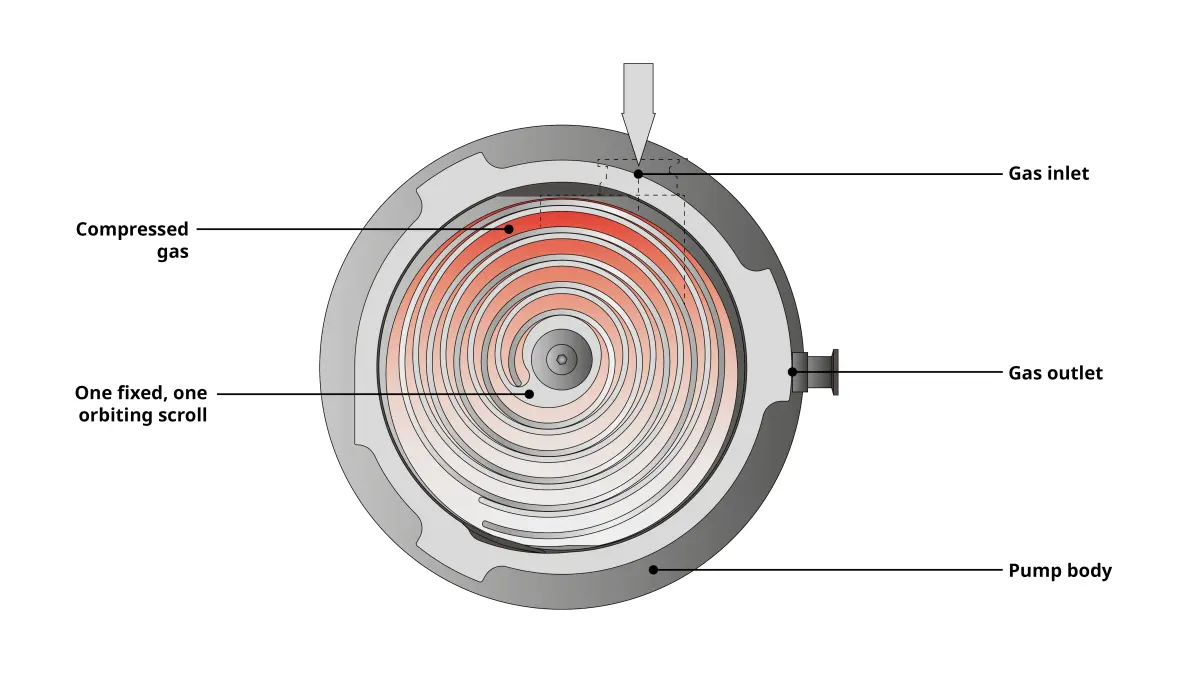

Types of scroll vacuum pumps

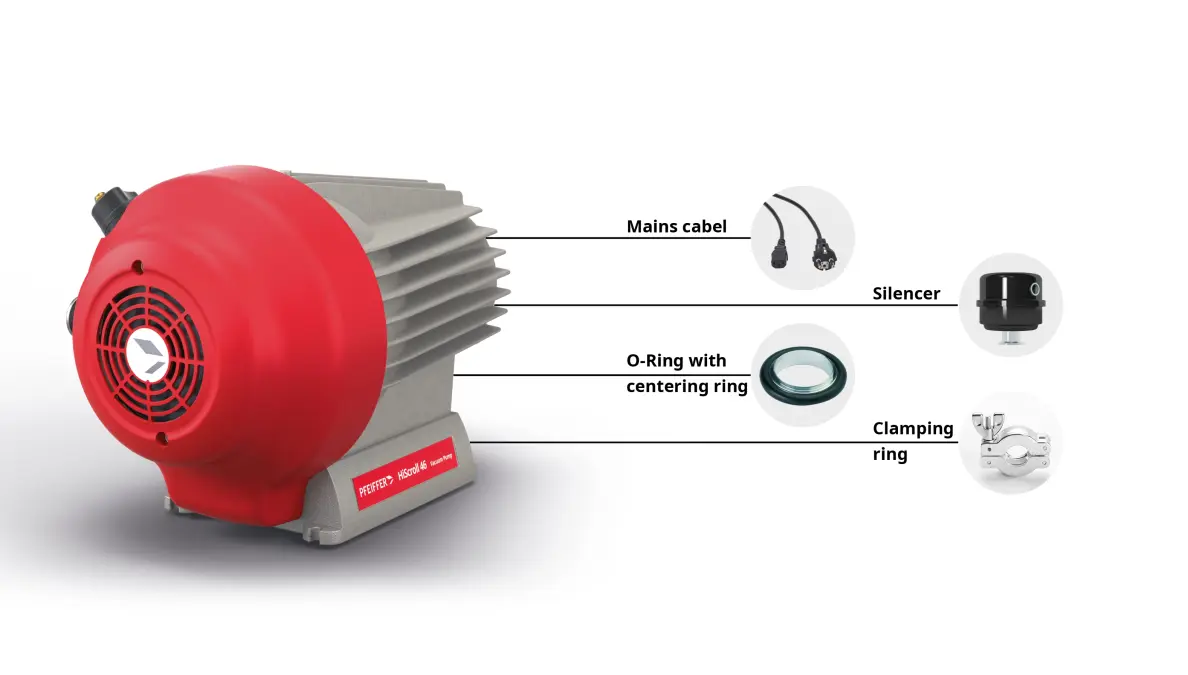

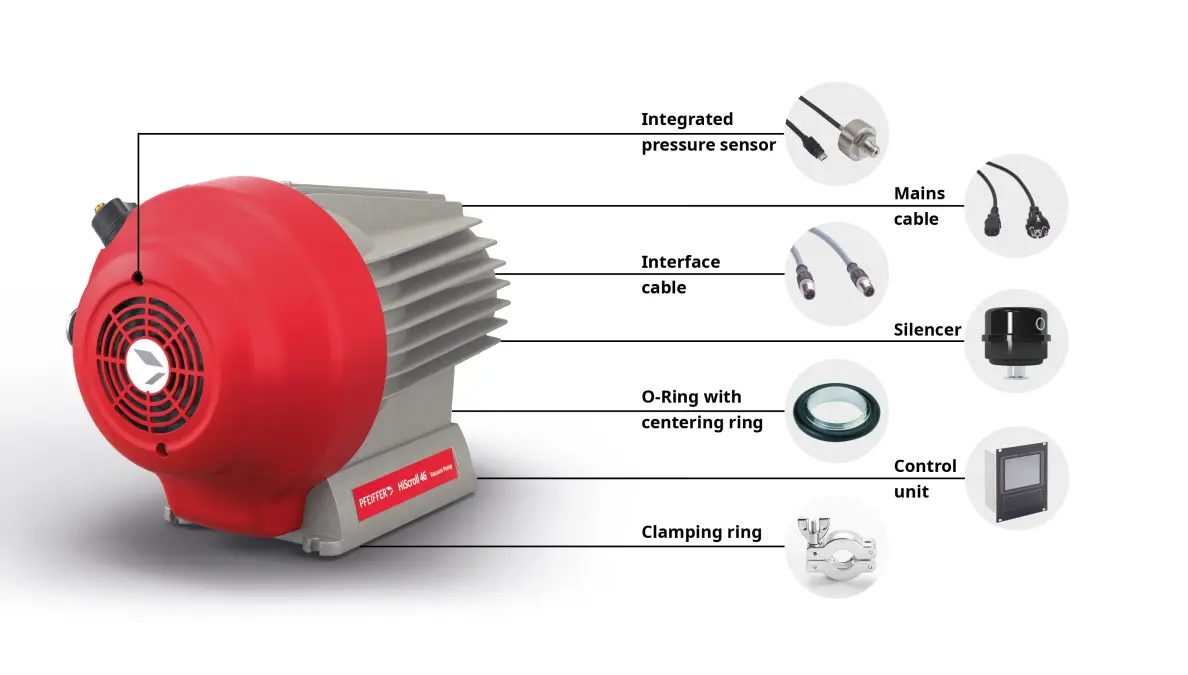

HiScroll vacuum pumps from Pfeiffer combine dry compression with a fully hermetic construction. Metallic corrugated bellows and static seals ensure tightness between the inside of the vacuum pump and the ambient air. This avoids contamination or leakage of the pumped medium.Product | Nominal pumping speed | Seal |

|---|---|---|

HiScroll 6 | 6 m3/h | hermetic |

HiScroll 12 | 12 m3/h | hermetic |

HiScroll 18 | 18 m3/h | hermetic |

HiScroll 46 | 43 m3/h | hermetic |