Types of turbopumps

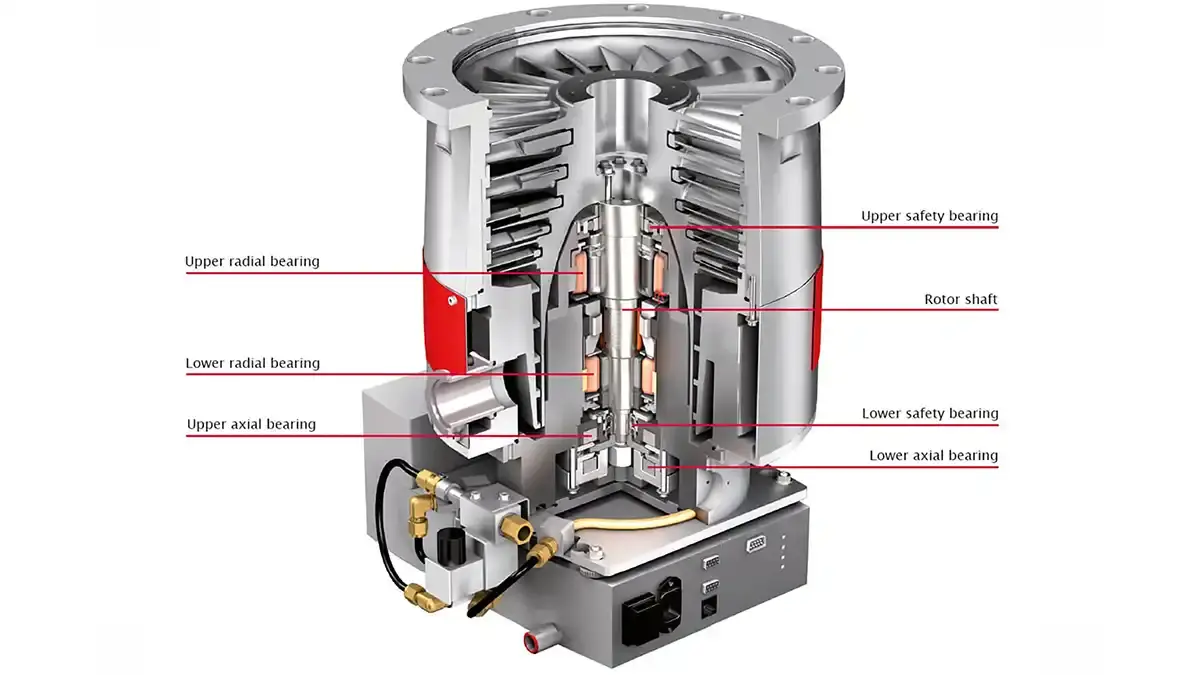

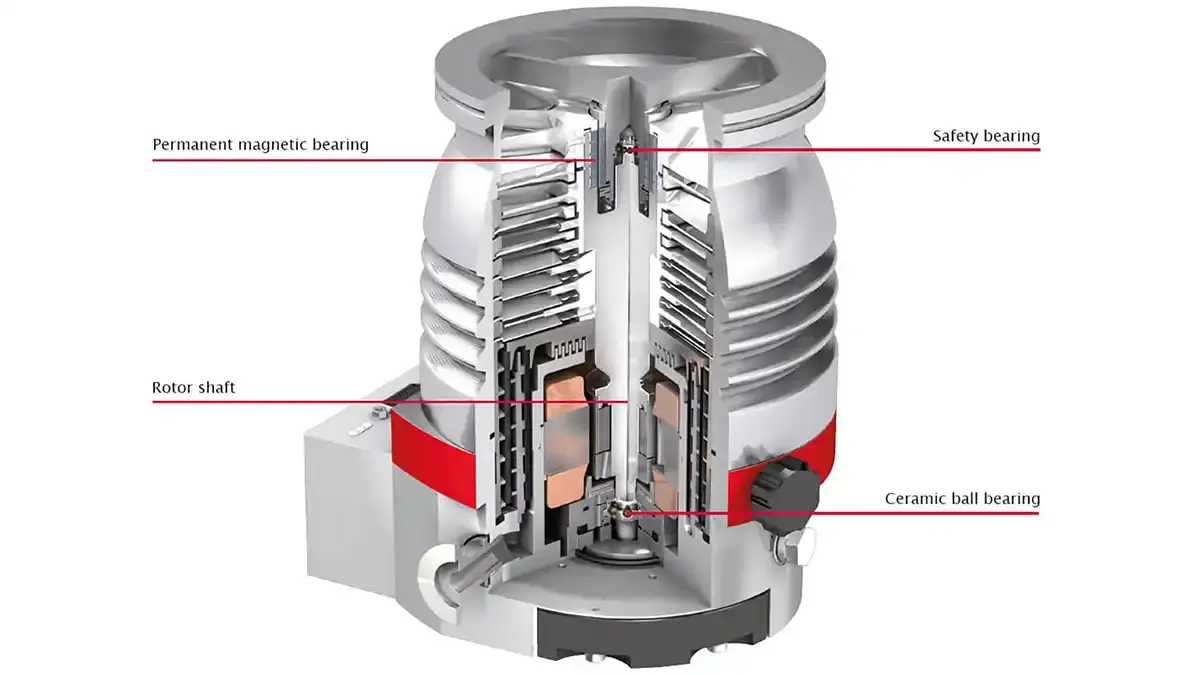

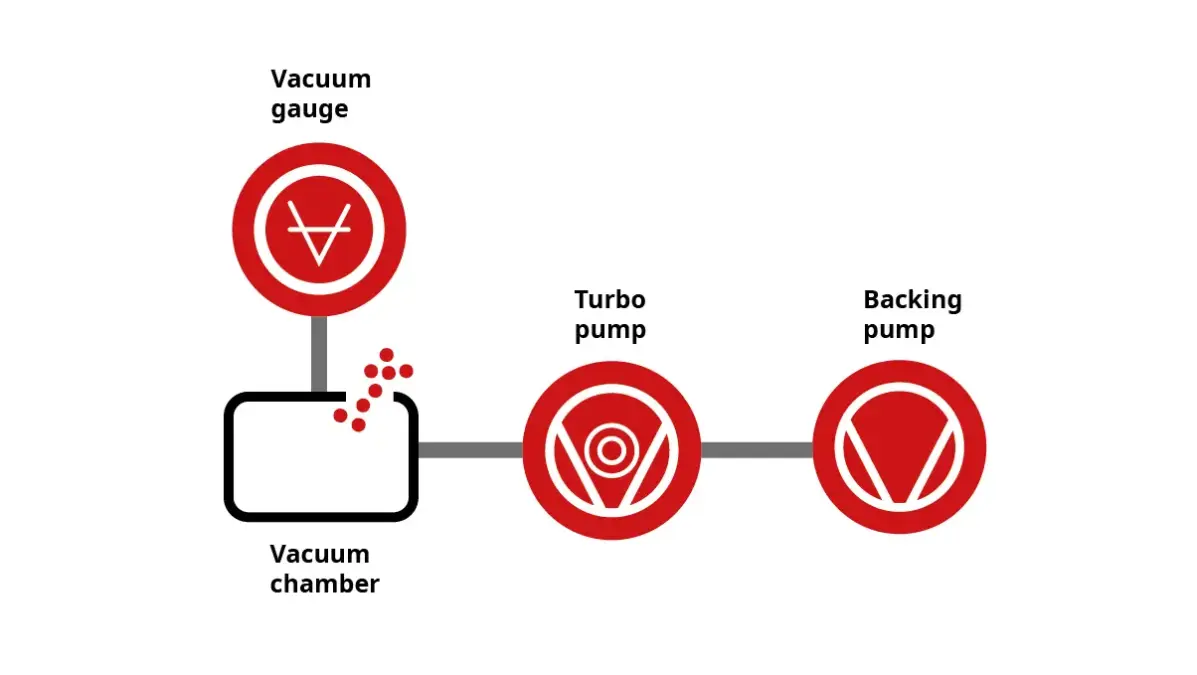

Generating high and ultra-high vacuum requires fast rotation of the high-speed rotors. They spin at up to 90,000 revolutions per minute (rpm). For comparison: A jumbo jet engine only reaches around 30,000 rpm. Such high speeds create substantial centrifugal forces, placing heavy stress on the materials of turbopumps, particularly the rotor assembly.To withstand these mechanical loads and ensure reliable operation, the design and performance of the rotor bearings are critical. Turbomolecular vacuum pumps from Pfeiffer are available with different bearing configurations: a mechanical, a magnetic as well as a hybrid bearing design. These bearing configurations are specially designed to limit stress on materials, ensure long service life, and support stable operation at high rotational speeds.