Leak Testing Services

Reliable leak detection for safety, environmental protection, and process integrity.

We conduct temperature-dependent leak tests within a range of -40 °C to +180 °C and at a maximum test pressure of 200 bar(a), using air, helium, and forming gas. These tests are essential for ensuring safety, protecting the environment, and maintaining the reliability of production processes and products.

Our global application labs provide a comprehensive range of services, including feasibility studies, contract leak testing, residual gas analysis, and test procedure development. With extensive expertise and a broad product portfolio, we offer tailored solutions to meet your specific leak testing challenges.

Services at a glance

Feasibility / Cycle-time studies

As part of a feasibility study, we analyze the technical requirements of your product to develop and implement an optimal leak test procedure for industrial tightness control. Whether for new products before market launch or existing ones requiring cycle-time optimization, we provide customized solutions that meet tightness requirements and respective regulations.

Your benefits

- Selection and validation of the most suitable test method for each unit under test.

- Access to multiple leak testing technologies and methods from a single source, with detailed comparisons for your specific part.

- A comprehensive feasibility study report outlining test execution, results, and recommendations tailored to your application.

- Cycle-time optimization to enhance industrial tightness control while minimizing capital investment.

- Gage R&R studies to establish a high level of quality assurance from the start of the product life cycle.

Feasibility study for container closure integrity testing (CCIT)

The quality and effectiveness of pharmaceutical products depend on proper packaging to maintain sterility throughout their shelf life. Our feasibility study provides a detailed understanding of your packaging and its CCIT capabilities. Using our three CCIT technologies, we assess the achievable detection limits and cycle times for your specific packaging.

Your benefits

- Three advanced CCIT technologies enable testing across a wide range of container types.

- Gain deeper insights into your product’s tightness and overall packaging integrity.

- Testing includes good samples and positive control samples with defined defects to simulate real-world leaks.

- A comprehensive feasibility study report detailing test execution, results, and tailored recommendations for your specific CCIT application.

Contract leak testing

When purchasing leak testing equipment is not a cost-effective option, our contract leak testing service provides a reliable alternative. In select regions, our highly trained field service technicians – certified to LT1 and LT2 standards (DIN EN ISO 9712) – can perform on-site leak detection for you.

Your benefits

- Leak testing of individual parts or small production series where investing in dedicated equipment is not economical.

- Access to a wide range of leak testing technologies and methods tailored to your specific requirements.

- Detailed laboratory reports with precise test results.

- Identification and analysis of contamination sources and foreign substances.

Residual gas analysis

We offer residual gas analysis for vacuum systems and tightness control using a wide range of tracer gases, including air components and electrolytes. The results are provided to you in a comprehensive, detailed protocol.

Your benefits

- Qualitative gas detection (1-200 u) for leak detection and outgassing measurements.

- Quantitative measurement of leakage and outgassing rates across multiple gases.

- Correlation of sensitivities using well-characterized calibration standards for new media.

- Identification and characterization of contamination sources and impurities.

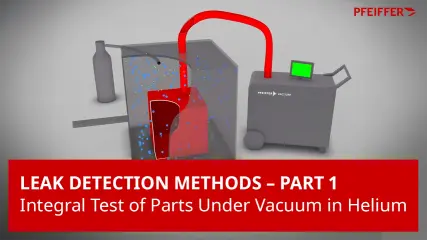

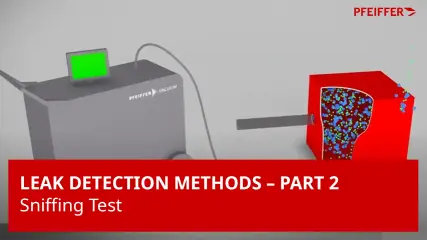

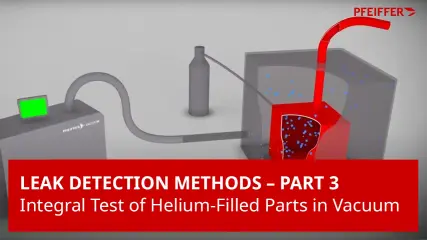

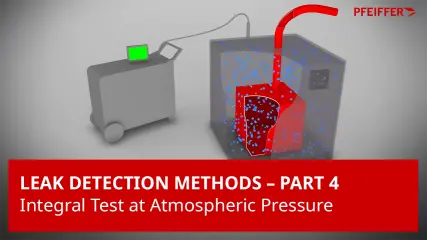

Leak detection methods

Our leak testing application labs

-

Pfeiffer Vacuum GmbH

Asslar (Germany)

-

Dreebit GmbH

Dresden (Germany)

-

Pfeiffer Vacuum SAS

Annecy (France)

-

Pfeiffer Vacuum Inc.

Indianapolis (USA)

-

Pfeiffer Vacuum (Shanghai) Co., Ltd.

Wuxi (China)