Product family | Technology | Medium | Oxidation gas |

|---|---|---|---|

CT-BW | gas burner | O2 or compressed dry air | |

CT-PW | plasma torch | compressed dry air | |

CT-TW | electrical heater | ambient air | |

CT-TW-H | electrical heater, H2 | ambient air | |

CT-W | water | - | |

CT-D | granulate | - | |

CT-D-E | granulate | - | |

CT-D VLC | granulate | - | |

CT-PF | filter | - |

Innovative solutions for a clean environment

We take responsibility for managing your emissions and adapt proven processes such as pollutant burning, scrubbing, filtration or absorption to your specific requirements.

Types of gas abatement systems

Thermal gas treatment

Our various thermal gas treatment systems combine high-temperature combustion of hazardous gases in the reaction chamber with an advanced wet scrubbing process to efficiently remove waste gases and pollutants. They ensure the effective destruction of hazardous and perfluorinated compounds (PFC) while minimizing environmental impact.

These systems deliver compliance with stringent emission regulations through a proven and sustainable approach, making them ideal for a variety of industries that require reliable gas abatement, such as the semiconductor and chemical industries, as well as research and development.

Wet gas treatment

Our wet gas treatment systems, also known as wet scrubbers, effectively remove pollutants, particles and soluble gases from industrial exhaust streams. Through liquid absorption and chemical reactions, these abatement systems ensure high removal efficiency for acidic gases, volatile organic compounds (VOC) and dust.

Thanks to its lower energy requirements, wet gas treatment is a reliable and versatile solution to meet stringent environmental regulations while maintaining operational efficiency.

Dry bed absorber

The innovative dry bed absorption technology from Pfeiffer safely removes toxic and corrosive gases through chemisorption using a special granulate. This converts the gases into stable, non-volatile solids. The chemicals, now permanently bound to the granulate, can then be disposed of safely in accordance with local regulations.

This method does not require fuel gas or water and produces no liquid waste. Therefore, it provides a highly efficient solution with low media requirements for industrial gas treatment, particularly for the semiconductor industry and research and development.

Filter systems

Our dry particle filter reduces fine dust emissions to a minimum. This system can be combined with our thermal gas treatment to achieve best-in-class particle removal efficiency.

As the filter collects the dust at the point of use, before the exhaust duct, it minimizes the need for the downstream exhaust to be cleaned manually. This lowers facility operating costs.

Applications

Gas abatement systems from Pfeiffer are essential for maintaining a clean and safe production environment, particularly in the semiconductor industry. From etching, chemical vapor deposition (CVD), epitaxy, atomic layer deposition (ALD), ion implantation and thin film deposition to extreme ultraviolet (EUV) lithography, our advanced technologies ensure the reliable removal of hazardous process gases right at the point of use: thermal gas treatment, wet gas treatment, dry bed absorber and filter systems, or a combination of these.Each industry has unique requirements and safety standards. To discover the best gas abatement solution for your needs, contact our experts.

Gas abatement services

From installation and commissioning to maintenance, upgrades, and system checks, our expert team provides tailored support to keep your equipment operating at peak performance.

We also offer operating cost analysis, Fourier transform infrared spectroscopy (FTIR) gas measurements, spare parts supply, and disposal services, making sure your system remains safe, compliant, and cost-effective.

Designed for your process: Customized gas abatement solutions

Our in-house developed modular systems enable us to tailor each solution to your specific requirements.

FAQ

What is a gas abatement system and how does it work?

Gas abatement systems eliminate hazardous pollutants and greenhouse gases generated during manufacturing processes, such as in the semiconductor manufacturing or in industrial gas handling. Waste gas cleaning is essential to ensure that these gases can be safely released into the atmosphere without posing harm to humans, animals, or the environment. The diverse properties of the various waste gases means that they require different treatment technologies. These can include thermal oxidation, wet treatment, dry bed abatement, particle filtration, or a combination.

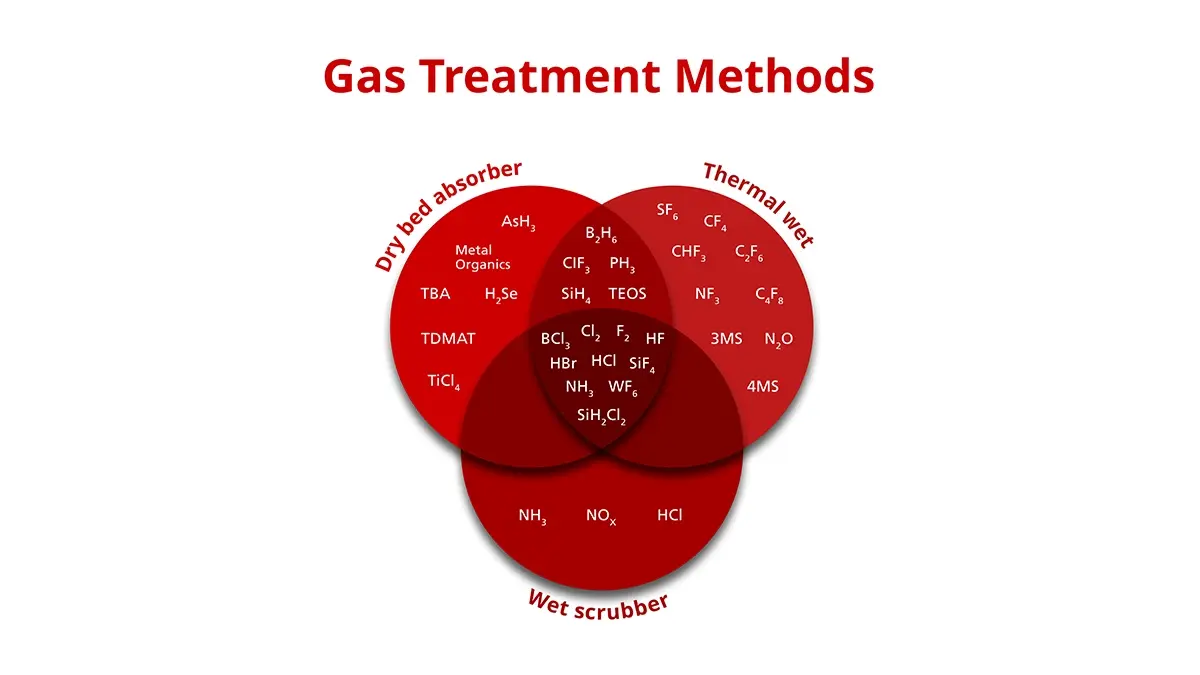

Thermal wet: Combines thermal and wet treatment technology to abate a broad variety of waste gases. It changes the chemical composition of harmful process gases via thermal oxidation and dissolves water-soluble gases as well as byproducts in the downstream wet stage.

Wet scrubber: This process involves scrubbing water-soluble, harmful pollutants in the exhaust gas by absorbing and converting them into the liquid phase.

Dry bed absorber: A dry bed absorber is a gas abatement system that removes waste gases by passing them through a solid absorbent bed, where pollutants are chemically or physically bound. This method efficiently treats harmful process gases, ensuring safe and environmentally compliant emissions. Once saturated, the absorbents are replaced or regenerated for continuous operation.

Filter systems: The particle filter reduces fine dust emissions with dry filter elements. This allows you to efficiently clean particle-loaded exhaust air flows, such as those produced during particle-prone semiconductor processes. If required, the particle filter can be installed downstream of our thermal gas abatement systems.

What are the advantages of gas abatement technology from Pfeiffer?

Gas abatement systems from Pfeiffer offer high efficiency, flexibility, and cost-effectiveness, making them the ideal choice for semiconductor manufacturing and other demanding industries. Key advantages include:

- Durable: Built with high-quality materials, our systems ensure long-lasting performance and lower operational as well as after-sales costs.

- Flexible: We offer all major abatement technologies, allowing high flexibility in system choice according to the demands of the individual application.

- Modular: Our abatement systems combine different technologies for tailored solutions.

- Safe: Built-in safety features such as standard gas sensors, emergency N₂ dilution, bypass valves and backup options ensure maximum safety in case of an emergency.

How do I choose the right gas abatement system for my application?

Type of exhaust gases

Different gas abatement systems are designed to handle specific types of gases. For the most common gases produced in the semiconductor and chemical industries, as well as R&D and other comparable industries, waste gas abatement technologies are recommended as shown in the graphic below.

Specific process operation mode

How your process operates can have an impact on the suitability of a particular gas abatement technology. One technology that is ideal for continuous production processes may not be the most cost-effective for infrequent operation, such as in R&D. And yet another may be the best choice for semi-continuous production processes or partially interrupted operation. Our experts are happy to support you in identifying the matching technology for your specific application.

Specific facility requirements

The infrastructure of your facility can also have an impact on which technology suits best. Different gas abatement technologies require different footprints, so the available space for installation of the waste gas treatment system must be taken into consideration. Furthermore, the available media supply such as electricity and nitrogen is another important factor, as well as additional technology-specific requirements such as oxygen, fuel gas and fluids.

To find the right gas abatement system, contact our experts.

How do gas abatement systems support environmental protection?

We are committed to minimizing the environmental impact of waste gas emissions through advanced gas abatement technology. Our systems effectively reduce harmful emissions, including highly persistent PFC gases like CF4, SF6, and NF3, which have extreme global warming potential. By efficiently cleaning these gases at the point of use, our gas abatement systems help protect the climate and reduce industrial emissions.

Our abatement solutions meet all important safety standards and ensure compliance with strict air quality laws, including Germany’s TA-Luft regulation. Additionally, our ISO 14001 and ISO 9001 certifications reflect our commitment to industrial sustainability and high-quality production.

By combining cutting-edge technology with a focus on sustainability, we provide solutions that benefit both your operational efficiency and your environmental footprint.

Does Pfeiffer also provide customized planning for gas abatement solutions?

Every installation has unique requirements, which is why gas abatement systems from Pfeiffer feature a modular design that can be customized to your specific waste gas treatment needs. We work closely together with you to develop an efficient, cost-effective, and sustainable solution tailored to your process and application.

As a full-service provider, we ensure detailed project planning, from initial consultation to commissioning, and continue to support you with comprehensive after-sales and service to keep your system running at peak performance.

Customized gas abatement solutions

What makes Pfeiffer a leader in gas abatement innovation?

At Pfeiffer, innovation is at the core of all our gas abatement systems. As a global technology leader and one-stop supplier for abatement technologies, we provide the most advanced and efficient solutions for cleaner and more sustainable industry standards, especially in semiconductor manufacturing.

Our in-house research laboratory allows us to continuously develop cutting-edge environmental technologies. Furthermore, we actively collaborate with universities and research institutes, supporting the development of new manufacturing processes by ensuring safe and compliant gas abatement.