Turbopumps with Hybrid Bearings

:grayscale(false):format(png))

What is a hybrid bearing?

The generation of high and ultra-high vacuums requires particularly fast rotations. The demands on the turbopump and its bearing are, therefore, correspondingly high.

Hybrid bearing turbopumps are particularly suited for the generation of high and ultra-high vacuum. The hybrid bearing combines a ceramic ball bearing on the fore-vacuum side with a permanent-magnet radial bearing on the high-vacuum side, making it particularly robust and dependable. The permanent magnet bearing provides hydrocarbon-free rotor stabilization, while the ceramic ball bearing protects the rotor from external vibrations – optimal conditions for vacuum generation.

:grayscale(false):format(png))

Sectional drawing of a hybrid bearing turbopump

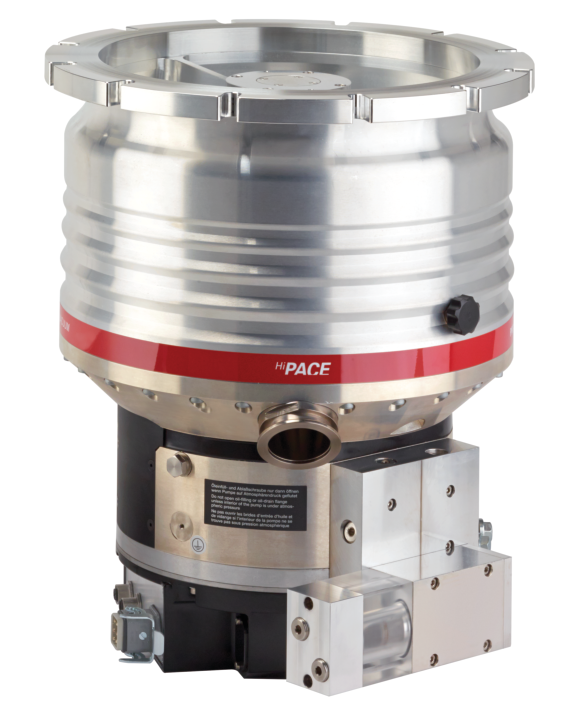

HiPace – Hybrid bearing turbopumps from Pfeiffer Vacuum

With HiPace, we offer you a complete product line of compact and powerful turbopumps adapted to your individual needs in the pumping speed range from 10 to 2,800 l/s. HiPace impresses with its high cost-effectiveness and flexibility: You can install almost all pumps in the series effortlessly in any mounting orientation. The innovative rotor design of HiPace turbopumps offers powerful pumping speed, excellent backing pump compatibility, high gas throughput rate, and superb compression for light gases. Furthermore, the proven hybrid bearing system guarantees you unrivaled reliability.

Hybrid bearings and their advantages in vacuum generation

From electron microscopy to leak detection and mass spectrometry: turbomolecular pumps are used in many applications. Due to the high speeds they achieve and often harsh ambient conditions, vacuum pumps require robust and reliable bearings.

Hybrid bearings offer numerous advantages in the field of vacuum generation:

Extended service life

Due to their low coefficient of friction, hybrid ceramic ball bearings ensure lower wear of the turbopumps. As a result, hybrid bearing turbo pumps require maintenance only every 4 years on average.Optimal for vibration-sensitive applications

With Pfeiffer Vacuum’s patented Laser Balancing technology, mass balancing for our hybrid bearing turbopumps is performed far more precisely than in conventional balancing processes. This provides you with a low-vibration turbopump with reduced noise emission – ideal for use in vibration-sensitive applications.Economic efficiency

Thanks to the robust design of hybrid bearing turbopumps, you benefit from fewer wear-related operating failures. In addition, you can easily replace the ceramic ball bearings and operating fluid reservoir on site in less than 30 minutes.

Fast run-up time

Pfeiffer Vacuum HiPace turbopumps feature a significantly reduced run-up time, which makes the pump ready for you to use even faster: an invaluable advantage for your production! Thanks to the integrated remote control and sensor functionalities, you can, for example, easily evaluate pump data such as temperature information. The improved diagnostics help maximizing pump availability.Powerful technology

With the consistently well-thought-out design of our HiPace turbopumps, you are always at the cutting edge of technology. The functional housing of our hybrid bearing turbopumps makes them extremely lightweight and versatile, while the innovative rotor geometry for quieter operation and significantly improved gas loads is setting new standards.

:grayscale(false):format(png))

:grayscale(false):format(png))

:grayscale(false):format(png))

:grayscale(false):format(png))

:grayscale(false):format(png))

:grayscale(false):format(png))

:grayscale(false):format(png))

:grayscale(false):format(png))

:grayscale(false):format(png))