Ion source, beamline & end station

Key requirements for semiconductor manufacturing include stable vacuum performance, high pumping speed, and compression for light gases to achieve low base pressure. Condensable materials are managed with high temperatures, while coatings ensure turbopump corrosion resistance. Low power consumption and minimal repair costs support long process lifetimes and low operating costs.

Learn more about source, beamline & end station

How does source, beamline & end station work?

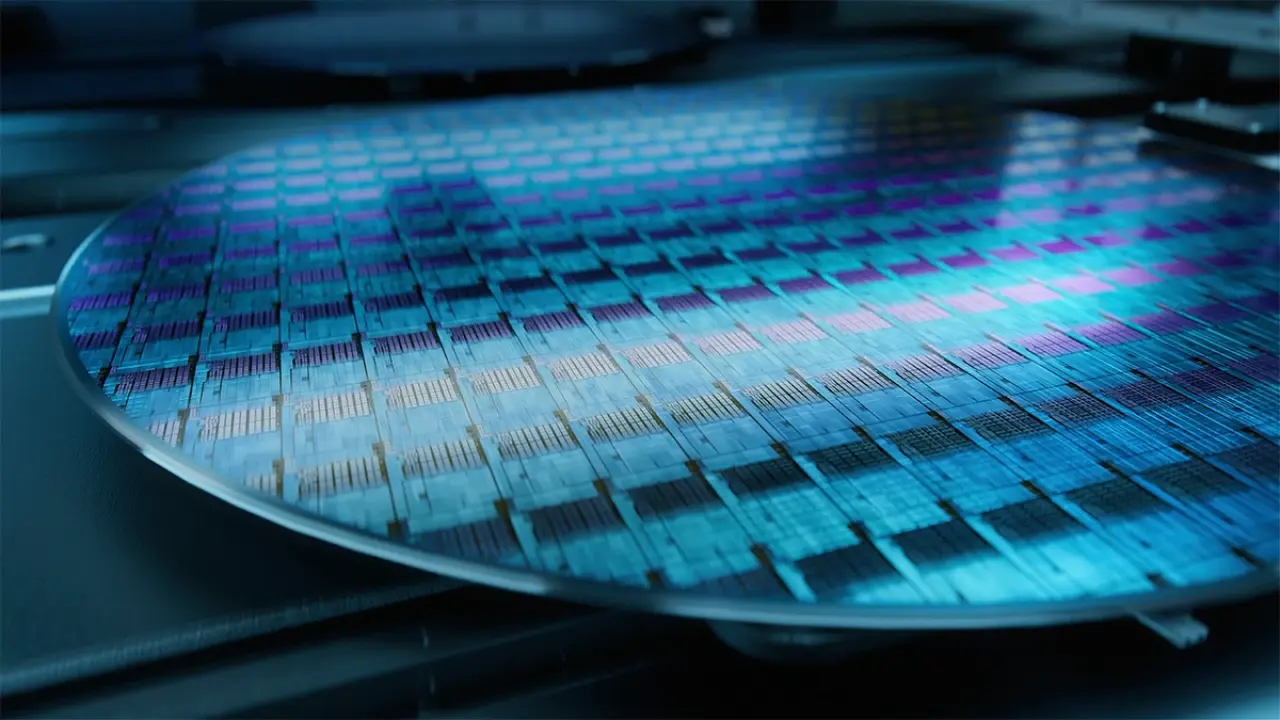

In order to generate the ions in the plasma, accelerate them and reduce their collisions on the way to the wafers, a high vacuum environment is required. Typical operating pressure is therefore in the range of 10-6 to 10-9 hPa (mbar). The source is the area where process gases are introduced, ionized by a hot filament, and extracted by an electrode. Only a few percentage of the introduced gas is ionized and extracted. Most common gases used for Implant process are Arsine (AsH3), Phosphine (PH3), Borane (BH3), or even Germanium (Ge). The beam line is the area where the ions are focused and accelerated by magnetic fields, generated by mass separation magnets. The end-station is the area where the implantation of the dopant ions occurs on the wafer. Load-lock chamber allows introducing the wafers from the atmosphere into the implantation tool.

What vacuum conditions are required for source, beamline & end station?

Typical target pressure for the ion source is in the range of 5·10-6 hPa (mbar). Ion implantation processes use hazardous and reactive materials which need to be handled by vacuum pumps. Turbopumps for Implant process should be designed to stand such chemistries, and on some recipes (based on PH3 or Ge) we recommend to use heated versions to prevent by-product accumulation.

Required pumping speed is commonly between 1,200 to 3,000 l/s, depending on equipment & wafer size. Regarding dry pumps on the source area, specific leak check is mandatory as any single leak will drastically reduce process lifetime. N2 purge is mandatory and should be process grade.

In the beam line area, typical pressure is in the range of 9·10-7 hPa (mbar). Depending on the type of implant performed, several corrosive turbopump models can be used, commonly with pumping capacity of 700 - 1,200 l/s each.

In the end station area, typical pressure is in the range of 5·10-8 hPa (mbar), mainly insured by cryo pumps. In the load-lock chambers the process is considered as absolutely clean. Vacuum requirement in this area is the range of 9·10-7 hPa (mbar), typically HiPace turbopumps up to 300 l/s suction speed are used.

What are the best vacuum solutions for source, beamline & end station?

Pfeiffer provides a full range of turbopumps and primary dry pumps designed to handle these challenges. Our HiPace turbopumps with hybrid bearings provide high vacuum and high temperature operation. Featuring optional corrosion resistance, our HiPace series are qualified at major OEMs on the most advanced ion implanter tools.

Our A604H model from A4 series is well designed for Implant applications for operation at the basement level. Specifically designed for source chamber, the A124H MD model is compact for easy integration and features high process robustness for increased lifetime.

For the pumping of differential seals, our ACP series are qualified at major implant tool manufacturer. As a primary pump for load lock chambers, our integrated solutions are the perfect fit for this application.