:grayscale(false):format(webp))

Leak Testing with Tracer Gases and Air

Tracer gas and air leak detectors are essential in industries where even tiny leaks can be catastrophic. Learn more about how Pfeiffer Vacuum leak detectors keep industrial processes safe and efficient.

:grayscale(false):format(webp))

Leak detection solutions

Our products for your applications

Due to these variable and unique conditions that arise for different test objects in different industries, it is highly relevant to find the most suitable leak testing technology for the individual case and also the right product for that. Pfeiffer Vacuum has the most extensive leak testing portfolio on the market.

It does not matter whether you need to find water, oil, fuel, refrigerant, gas, steam, air or vacuum leaks. From miniature electronics to large vessels, from media leaks to gas leaks in vacuum systems, the requirements for leak detectors are as diverse as the range of industrial products. The wide range of leak detectors from Pfeiffer Vacuum offers solutions for all these requirements, for example portable or modular devices, helium leak detectors for sniffing or customized leak detection solutions such as leak test modules for an optimal integration into production lines or leak detectors for the Pharma and CCIT economy.

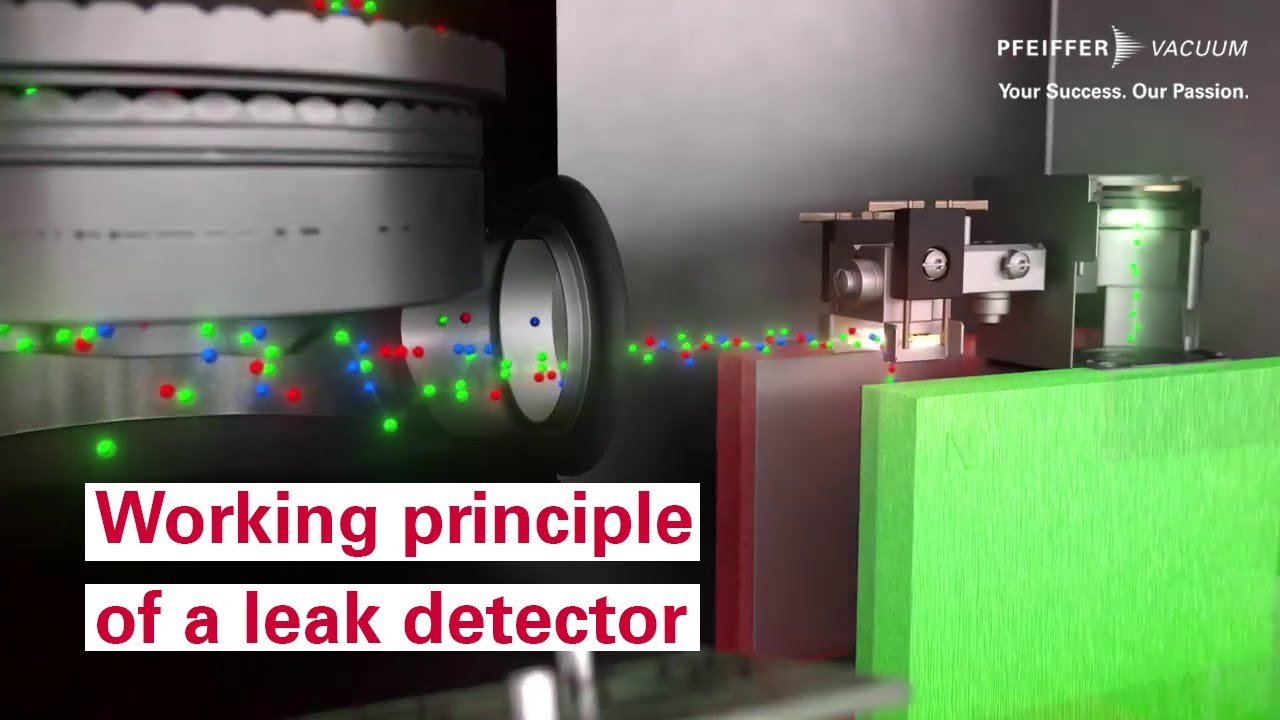

Working principle of a leak detector

Our leak detection solutions

Leak detection technologies

In the field of leak testing, a variety of technologies have been established to detect leaks, including leak testing with air, with tracer gases or optical emission spectroscopy.

The selection of a suitable technology for leak testing depends on various influencing factors. The test object itself is at the center of the considerations for a leak test, as the leakage rate requirement should ensure a functional tightness of the part. Decisive factors in the selection of a technology for example include the temperature, the geometry of the test specimen and the cycle time requirements.

Furthermore, it is essential to create test conditions that are as real as possible with regard to the subsequent use of the test object. Due to the variable and unique conditions that arise for different test objects in different industries, it is highly relevant to find the leak test technology that is best suited for the individual case.

Pfeiffer Vacuum has the most extensive leak testing portfolio on the market. The available test technologies are featured by quality, accuracy and user-friendliness, and offer top performance, reliability as well as short cycle times.

Want to learn more about these leak detection technologies?

Then check out our leak detection fundamentals for more useful information out of the leak testing world and get advice on how to find the right methods and equipment for your leak testing process.

:grayscale(false):format(webp))

:grayscale(false):format(webp))

:grayscale(false):format(webp))

:grayscale(false):format(webp))

:grayscale(false):format(webp))

:grayscale(false):format(webp))

:grayscale(false):format(webp))

:grayscale(false):format(webp))

:grayscale(false):format(webp))

:grayscale(false):format(webp))

:grayscale(false):format(webp))

:grayscale(false):format(webp))