Vacuum technology for semiconductor industry

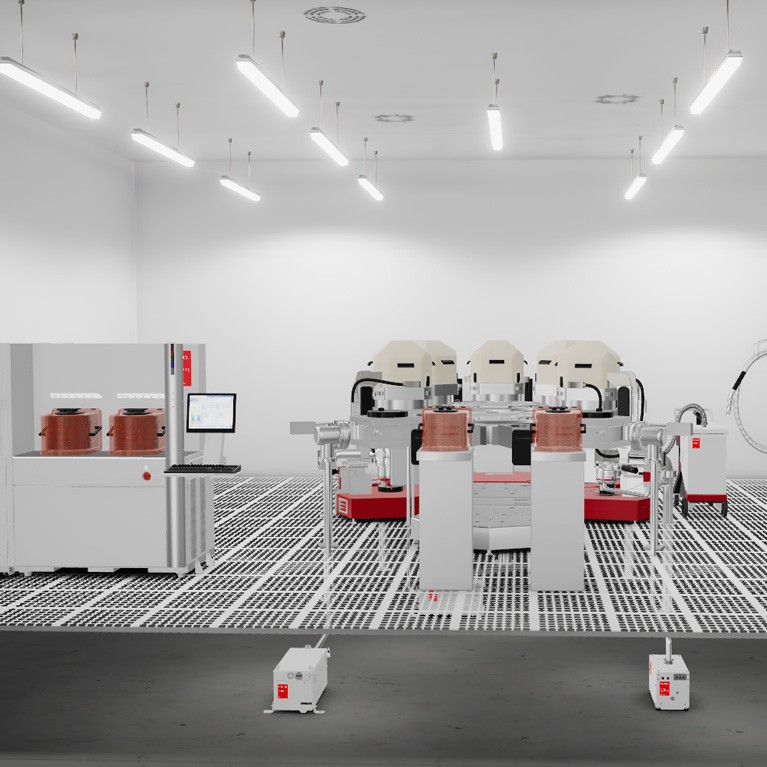

The semiconductor industry drives technological progress, influencing our daily lives through devices such as smartphones and AI. Central to these innovations are microchips – tiny yet incredibly complex components that require highly precise and contamination-free manufacturing environments.With nearly 40 years of expertise, Pfeiffer Vacuum+Fab Solutions offers a wide and high-quality portfolio, serving the entire semiconductor manufacturing process – from vacuum chambers to abatement systems. As a one-stop supplier of vacuum and fab solutions, we have a deep understanding of semiconductor industry challenges. Pfeiffer is the right partner to create innovative products that support semiconductor actors in their wafer fabrication challenges. Our role is to connect the dots through product synergies and provide tailored solutions to ensure high yield, reduce energy consumption, and minimize carbon footprint.