Multi-stage Roots Pumps

Discover reliable and versatile multi-stage Roots pumps for high vacuum applications. Ideal for clean and dry processes, they offer high pumping speeds and low ultimate pressures, making them perfect for semiconductor manufacturing, vacuum coating, and R&D applications.

:grayscale(false):format(webp))

Discover the advantages of multi-stage Roots pumps

With their frictionless technology, multi-stage Roots pumps fall into the category of dry-running positive displacement vacuum pumps and are the ideal choice for clean vacuum requirements, offering a particle- and hydrocarbon-free environment. They provide superior pumping speed, exceptional ultimate pressure, and outstanding gas handling capabilities. The absence of wearing parts ensures long-term stability and reliability. Multi-stage Roots pumps are equipped with a universal power supply and are compliant with CE standards, UL/CSA certified, SEMI S2 certified, making these pumps suitable for numerous applications.

Choosing the right dry pump

The type of multi-stage Roots pump required is influenced by the specific application it is intended for. Different applications demand varying pumping speeds, ultimate pressures, and gas handling capabilities. For instance, in semiconductor manufacturing, where load-lock and transfer chambers are critical, compact, and integrated pumps are preferred for their fast pump down cycles. On the other hand, surface analyzers and leak detectors may necessitate pumps with specific gas port options to meet their requirements. Additionally, in particle accelerators, pumps with resistance to radiation and other specialized features are essential. Therefore, understanding the unique demands of each application is crucial in selecting the most suitable multi-stage Roots pump to ensure optimal performance and efficiency.

Ideal solutions

for clean vacuum applications

The ACP and A 100 L series, as well as the TORRI BD pumps, are cutting-edge solutions designed specifically for clean processes that require a high level of purity and reliability. The ACP series, with its air-cooled design, offers a constant performance and versatility, making it an ideal replacement for scroll and oil-sealed pumps. On the other hand, the A 100 L and A 200 L are compact and integrated pumps, perfect for frequent fast pump down cycles in load-lock and transfer chambers. Another compact option for load lock chambers are TORRI BD vacuum pumps. They are energy-efficient and feature low ultimate pressure as well as best-in-class chamber pump-down time. All of these pumps offer high throughput, low maintenance costs, and are compliant with industry standards, making them the optimal choice for clean vacuum processes in various industries.

Unbeatable reliability dry pumps

for harsh chemical processes

When it comes to handling the most demanding chemical environments, the A3 and A4 series by Pfeiffer Vacuum are the top choices. These multi-stage Roots pumps are purpose-built to withstand corrosive and aggressive chemicals, providing unparalleled performance, efficiency, and long-term stability. With their robust design and corrosion-resistant materials, these process pumps excel in applications such as semiconductor etching, chemical vapor deposition (CVD), and other harsh chemical processes.

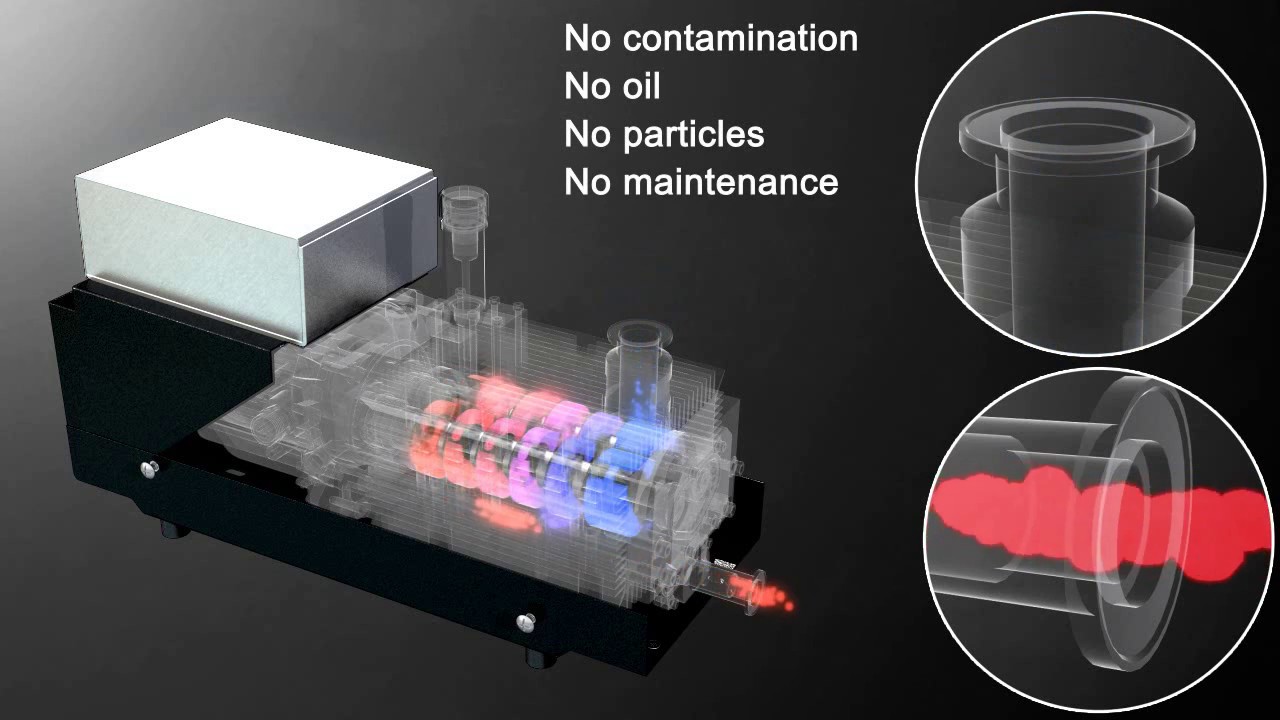

Understanding the working principle of multi-stage Roots pumps

Operating on a unique principle, multi-stage Roots pumps enable efficient and reliable vacuum performance. These pumps consist of two interlocking rotors with lobes, which rotate in opposite directions without making contact. As the rotors spin, they create chambers of varying volumes, causing the gas to be trapped and transported from the inlet to the outlet. The multi-stage configuration enhances the pumping efficiency by compressing the gas in multiple stages, resulting in higher pressure differentials, and improved overall performance. With a frictionless design, these pumps eliminate the need for lubricants and sealing materials, ensuring a particle- and hydrocarbon-free vacuum environment.

Experience the functional principle and design of the multi-stage Roots pump from Pfeiffer Vacuum in this 3D animation.

Versatile solutions for diverse applications

Extensively utilized across diverse industries, multi-stage Roots pumps play a crucial role in various fields, including semiconductor manufacturing, where they are essential for load-lock and transfer chambers, as well as in the production of surface analyzers, leak detectors, and particle accelerators. Additionally, multi-stage vacuum pumps find their place in turbo pumping stations, laboratories, lamp manufacturing, gas industry processes, vacuum coating, cryo pumps regeneration, plasma cleaning, and various drying and cleaning applications. Their adaptability and robust performance make them indispensable in freeze-drying, laser gas recycling, and even in the management of high-value gases. Whether it's in research and development or industrial settings, the versatility of multi-stage Roots pumps ensures they are the go-to solution for achieving optimal vacuum performance and meeting the specific requirements of diverse fields and applications.

Pumping a wide range of chemicals with multi-stage vacuum pumps

Multi-stage Roots pumps offer exceptional versatility when it comes to handling various chemicals across different industries, including corrosive and aggressive substances. From acids and solvents to gases and vapors, multi-stage Roots pumps can handle a multitude of chemical compounds with the highest reliability. The robust construction and materials of the A3 and A4 pumps ensure resistance to chemical attack, providing long-term durability and consistent performance even in challenging environments.

Sustainable solutions

Multi-stage Roots pumps offer several environmental benefits, making them a sustainable choice for various industries. First, these pumps are designed with energy efficiency in mind, effectively reducing power consumption and minimizing the overall carbon footprint during operation. Some models are equipped with frequency converters, allowing operators to optimize energy usage by adjusting rotational speed based on specific application needs, resulting in additional energy savings. Moreover, their superior pumping speed and exceptional gas handling capabilities enable efficient process management, leading to reduced material wastage and lower energy consumption. Furthermore, these pumps provide reliable and long-lasting performance, contributing to sustainable operational practices and reducing the environmental impact associated with frequent pump replacements. All these features make multi-stage Roots pumps an environmentally conscious and responsible choice for modern industries.

:grayscale(false):format(webp))

:grayscale(false):format(webp))

:grayscale(false):format(webp))

:grayscale(false):format(webp))

:grayscale(false):format(webp))

:grayscale(false):format(webp))