Efficient Operation Thanks to Modern Rotary Vane Pumps

Rotary vane pumps are a reliable option for a wide range of applications. With modern pumps, you can achieve efficient operation and maximum performance. Find the right model for your specific requirements here.

:grayscale(false):format(webp))

Our rotary vane pumps are among the most frequently used pumps

Durable and robust, just right for your application

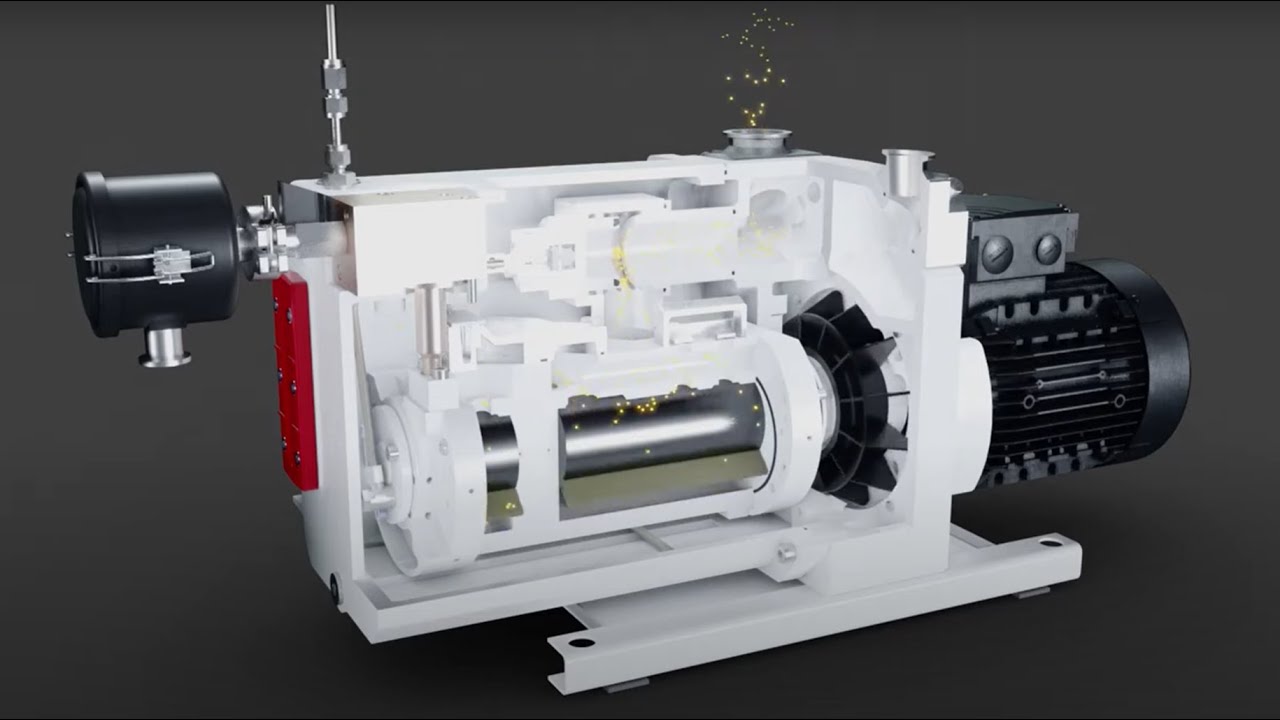

For many years, rotary vane pumps from Pfeiffer Vacuum have been among the most frequently used pumps for generating rough and fine vacuum. They are very durable and robust, regardless of whether they are used as backing pumps to generate the necessary inlet pressure for turbopumps or as stand-alone pumps. Rotary vane pumps belong to the group of positive displacement pumps, as they deliver an almost constant, low-pulsation volume flow, regardless of the type of gas.

The operating principle is based on an eccentrically mounted rotor with two or more movable vanes, which rotates in a housing. Rotary vane pumps from Pfeiffer Vacuum are oil-lubricated without exception. Special vacuum oils, also known as operating fluids, take care of sealing and lubricating the components, among other things, which enables very low ultimate pressure. In addition, the oil lubrication ensures a long service life, even in continuous operation.

:grayscale(false):format(webp))

Our service offer for rotary vane pumps

A choice of versions offers the right variant for every application

Pfeiffer Vacuum rotary vane pumps cover a very wide pumping speed range from 1.25 to 1,600 m3/h (at 60 Hz up to 1,920 m3/h). There are two different types to choose from when selecting a pump: Single-stage and two-stage rotary vane pumps.

Two-stage pumps are best suited for processes in the fine vacuum range. Single-stage models are preferred when the working pressure is predominantly in the rough vacuum range.

Maximum operational safety due to magnetic coupling

Many rotary vane pumps from Pfeiffer Vacuum are available with an optional magnetic coupling. This eliminates the need for the shaft sealing rings that are otherwise common with this type of pump. Maintenance of the shaft seal is therefore unnecessary and oil leakage is avoided with the magnetic coupling.

Need any help?

We are available for your questions

Our team of product experts is always available to answer your questions about our products and your applications.

Maximum service life, even in demanding processes

The selection of the oil, also called operating fluid, enables the rotary vane pump to be adapted even better to the process. For example, Pfeiffer Vacuum offers special oils for corrosive processes. All Pfeiffer Vacuum operating fluids were developed specifically for the respective pump type. Particular emphasis was placed on achieving optimum vacuum performance in combination with a long service life. By using accessories, the field of application of the rotary vane pump can be expanded even further. By using cold traps or adsorption traps, aggressive media can be separated upstream of the pump, thus extending the service life of both pump and equipment. Oil mist separators for the pump outlet ensure clean exhaust air. A wide range of other accessories for controlling pump characteristics enables the pump to be integrated into the customer's control and process monitoring system.

Areas of application for rotary vane pumps

Vacuum technology plays a decisive role in the manufacturing of many everyday products and in many areas of technical research. Here, the rotary vane pump is crucial for reliable vacuum supply.

All applications in rough and fine vacuum

Backing pump for turbo and Roots pumps

General laboratory applications

Analytics

Chemistry laboratory

Freeze drying

Process engineering

Operating notes for process adaptation

Ideally, the pumps are operated in a process window between 100 mbar and a pressure about a decade above the final pressure. Above 100 mbar, the exhaust oil separators clog very quickly due to the oily exhaust gas flow. In the final pressure range, the strong dependence of the pumping speed on the intake pressure takes effect. In this condition, it is not possible to run stationary processes.

Most models have the option of adding gas ballast to prevent liquid accumulation due to condensing moisture. The use of gas ballast affects pump performance data differently. For example, the achievable pumping speed of single-stage rotary vane pumps is reduced by the gas ballast component. This also increases the final pressure. However, due to the design, the gas ballast has no influence on the pumping speed of two-stage pumps.

Process optimization for rotary vane pumps

Advantages of rotary vane pumps

Adaptable and perfectly suited to your process

Reliability: Due to their simple structure, rotary vane pumps are extremely reliable pumps that have a long service life and high operational availability.

Performance: Rotary vane pumps can cover a wide range of flow rates and pressure ranges, allowing them to be used in both rough and fine vacuum.

Versatility: Since rotary vane pumps are mainly made of mechanical components characterized by high robustness, they are able to handle drugs with high solids content and aggressive chemicals. They can therefore also be used in processes with accumulating impurities and aggressive media.

Easy maintenance: Another advantage is the ease with which rotary vane pumps can be serviced and maintained. The components are quickly accessible and can in many cases be maintained by the user without outside assistance.

Low noise level: Compared to other vacuum pumps, rotary vane pumps have a relatively low noise level. This makes them a good choice for applications with noise sensitivity.

:grayscale(false):format(webp))

Rotary vane pump SmartVane 70

:grayscale(false):format(webp))

:grayscale(false):format(webp))

:grayscale(false):format(webp))

:grayscale(false):format(webp))

:grayscale(false):format(webp))

:grayscale(false):format(webp))

:grayscale(false):format(webp))

:grayscale(false):format(webp))

:grayscale(false):format(webp))

:grayscale(false):format(webp))

:grayscale(false):format(webp))

:grayscale(false):format(webp))

:grayscale(false):format(webp))

:grayscale(false):format(webp))