Roots Pumps as a Booster for Your Vacuum Application

Whether mechanical safety or intelligent integration is required: Our versatile portfolio offers tailor-made solutions for your requirements - even in explosive environments and with extreme pressure differences.

:grayscale(false):format(webp))

Functional principle and features of Roots pumps

Single-stage and multi-stage Roots pumps often also called rotary lobe pumps, Roots blowers or booster pumps, are technically dry-running positive displacement vacuum pumps. In Roots pumps, the gearbox and bearings are separated from the suctions chamber. The contactless operation of the lobes ensures technically dry operation. Single-stage Roots pumps cannot be used against atmosphere. In order to avoid excessive heating and expansion of the lobes, the pressure difference between the suction and pressure flange is crucial. This type of vacuum pump therefore requires appropriate backing pumps or cooling adapted to the pressure difference. Alternatively, several Roots lobe stages can be connected in series so that the pressure difference is distributed across the different stages. This principle can be found in our multi-stage Roots pumps, which can be used directly against atmosphere.

:grayscale(false):format(webp))

Our service offer for roots pumps

Areas of application and limitations of Roots pumps

Roots pumps serve as boosters for roughing pumps and increase the available pumping speed in lower pressure ranges where the efficiency of the roughing pumps is already decreasing. The combination of both vacuum pumps can therefore achieve a pressure that is approximately 10 times lower than the roughing pump alone.

Roots vacuum pumps generally have a pumping speed that is approximately 2 to 8 times higher than the downstream roughing pump. We therefore speak of a gradation ratio of 1:2 to 1:8. This ratio influences the pressure difference at the operating point, which in turn determines the required motor power of the pump.

There are various measures and pump designs to protect against overheating and overloading of the motor due to excessive pressure differences in the process.

Our specialists will be happy to advise you on the optimal configuration of your Roots pump.

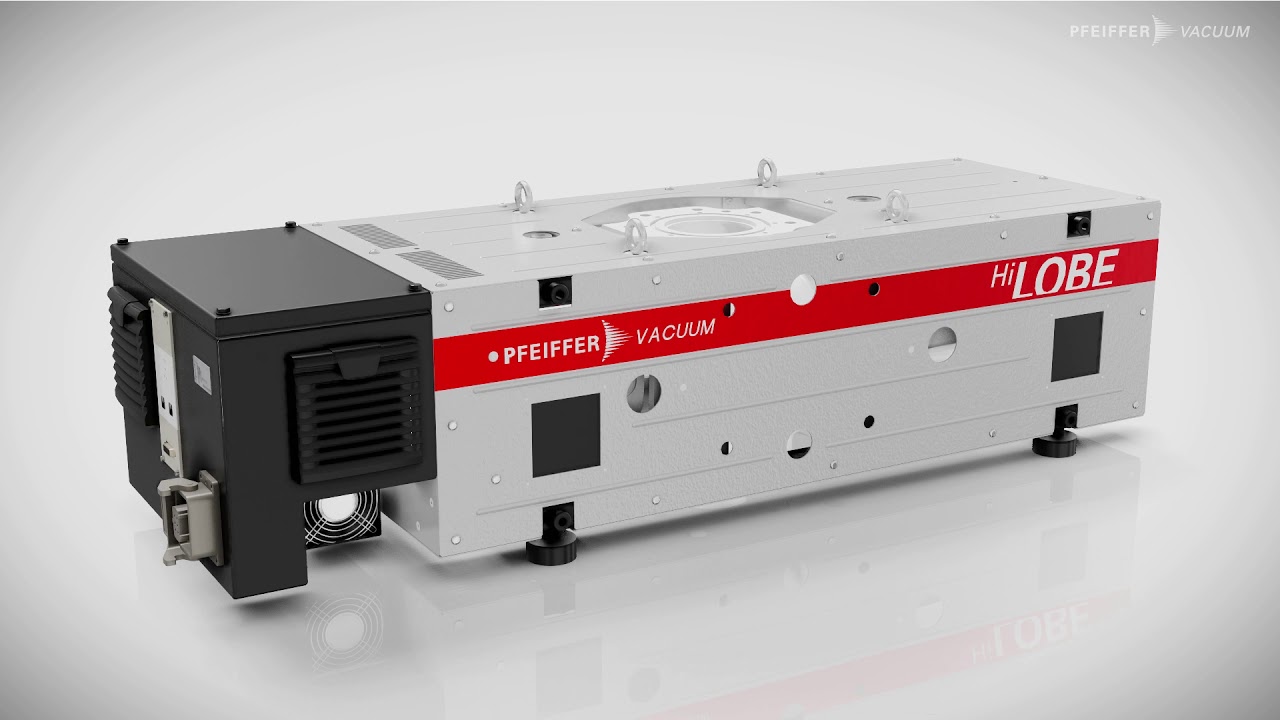

HiLobe

Roots pumps with the highest energy efficiency thanks to integrated intelligence

Intelligent and flexible

With their individual speed control, Roots pumps from the innovative HiLobe series can be adapted perfectly to customers’ specifications. Flexible installation positions allow the system size and installation costs to be reduced. The intelligent interface technology of the HiLobe enables optimal adjustment and condition monitoring of processes. This ensures a long service life and maximum operational reliability in your application.

Flexible control of the air- or water-cooling system enables individual temperature control of the HiLobe and thus ensures optimum adaptation of the pump temperature to your processes.

HiLobe Roots pump in 3D

High performance

HiLobe pumps are available in a pumping speed range of 520 - 13,600 m3/h. Their superior drive concept permits extremely high differential pressures for a booster pump to be reached for short periods of time. This reduces pump-down times by around 20% compared to conventional Roots pumps. In order to operate, Roots pumps require a suitable backing pump, adjusted to the gas flow, for the particular application.

Efficient

The innovative, integrated and wear-free motors with energy efficiency class IE5 and IE4 (depending on size) and optimized rotor geometries enable low operating costs and high availability. The drive of the HiLobe line is hermetically sealed and has a maximum integral leakage rate of 1 · 10-6 Pa m3/s. This saves costs and time-consuming maintenance of shaft seals. In addition, it prevents any contamination of the process gas. The use of sealing gas is unnecessary in most applications due to the sealing concept from the motor to the suction chamber.

Customer benefits of HiLobe Roots pumps

Efficient: Extremely short pump-down times due to superior, next-generation drive concept

Enhanced safety: Intelligent interface technology allows process monitoring (Industry 4.0)

Flexible: Vertical or horizontal pump mounting and variable control of the fan and pumping speeds permits adaptation to process variations

Durable: Hermetically sealed pump with leakage rate of < 1 ·10-6 Pa m3/s since outward dynamic seals are eliminated

Low operating costs: State-of-the-art motor technology (IE5 or IE4 standard, depending on pump size) and flexible speed control

Areas of application of the HiLobe Roots pumps

Lock chambers

Leak detection systems

Freeze drying/vacuum drying

Metallurgy

Electron beam welding

Vacuum furnaces

Steel degassing

Battery production

Vacuum packaging

Isolation vacuum

Distillation

Coating

Space simulation chambers

OktaLine

Safe and easily integrated Roots pumps

The suction speed of our robust OktaLine Booster pumps range from 145 to 3,230 m3/h. The high-precision manufacturing technology enables the highest compression values, which enable maximum pumping speed at the lowest gas outlet temperatures. The OktaLine series is usually equipped with an integrated bypass valve. This valve is purely mechanical and self-adjusting, consisting of a weight that opens along a guide piston above a specific differential pressure. It protects the pump from overheating by selectively creating a “short circuit” between the suction and pressure flange.

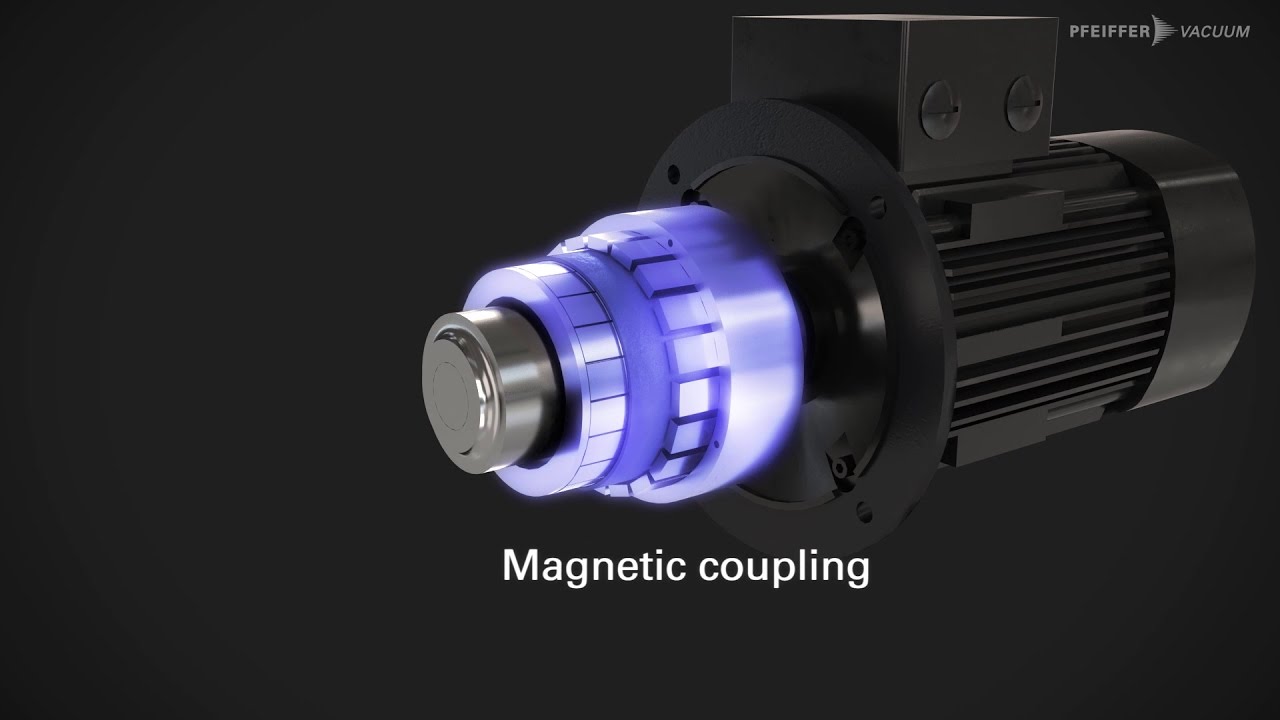

The OktaLine Roots pumps offer low operating costs with high availability, as they only require electrical energy and - if necessary for the process - a gaseous barrier medium (e.g. air). Thanks to convection cooling, operating costs are significantly lower than with water-cooled pumps. The (optional) magnetically coupled design makes leaky shaft seals a thing of the past. These pumps are therefore hermetically sealed and achieve very low leakage rates. Thanks to many years of experience with our all-rounders, there is a large variety of variants as well as an extensive selection of accessories that enable an individual pump configuration for your process.

Customer benefits of the OktaLine series

Flexibility and maximum process suitability thanks to the complete line of Roots pumps

Broad range of pumping speed from 145 to 3,230 m3/h

Fast evacuation thanks to high compression ratio and overflow valve

Maintenance-free, maximum reliability and highest uptime thanks to magnetic coupling

Low operating costs thanks to convection cooling and magnetic coupling

No thermal overload thanks to integrated overflow valve

Long service intervals and simple on-site maintenance

Areas of application of the OktaLine Roots pumps

Metallurgy

Simulation chambers

Packaging industry

Freeze drying/vacuum drying

Thin film technology

Electron beam welding

Load-locks

Chemistry and process technology

Industrial leak detection systems

OktaLine ATEX

Safe vacuum generation in potentially explosive areas

For processes in potentially explosive environments, or for evacuating explosive gases, we have developed ATEX-certified pumps in compliance with directive 2014/34/EU, which meet highest-level explosion protection requirements.

Pumping speeds in this series range from 280 to 8,100 m3/h. Depending on the requirements, equipment category 2 or 3 can be chosen. All pumps are suitable for temperature class T3, sometimes also T4 is possible.

The gear box and bearings in our Roots pumps are separated from the gas pumping chamber. The frictionless rotation of the lobes enables technically dry operation and high rotation speeds. With the magnetic coupling that comes as standard, we are able to offer hermetically sealed pumps with very low leakage rates. The magnetic coupling eliminates the need for shaft seals, which are inherently weak points if it comes to pressure surges and contamination of the process. Additional operational reliability can be achieved with optional vibration measurement accessories.

Customer benefits of the OktaLine ATEX Roots pumps

Highest level of protection for operators and ambient – even in the (very unlikely) case of an explosion, due to pressure surge resistance of PN16

Installation possible without additional flame arresters

Pumps are hermetically sealed (leakage rate < 10-6 Pa m3/s) – no zone entrainment (of explosive gases)

High reliability - no thermal overload thanks to integrated temperature sensor

Pumps can be operated without a bypass (ATEX protection even with passive rotation / windmilling)

No-hassle on-site service, also for the motor (can be replaced in the field thanks to ATEX IEC motors)

Flexible use due to variable differential pressure and rotational speed*

Ambient temperature range from -20°C to + 40°C

*when used with frequency inverter

Areas of application of the OktaLine ATEX Roots pumps

Chemical Industry

Pharmaceutical industry

Automotive

Heat treatment

Vacuum drying

Vacuum furnaces

Environmental Protection

OktaLine G

Gas circulation-cooled Roots pumps for high pressure differences and high pumping speeds

OktaLine G, which are also available, offer additional flexibility. These pumps are ideal for applications with high pressure differences and maximum gas throughput when compressing against atmosphere.

The OktaLine 8000 G is a special version of the conventional Roots pump. In various performance levels up to a nominal output of 200 kW, the OktaLine 8000 G achieves a suction speed of 4,000 - 12,000 m3/h against atmospheric pressure. This means that the gas circulation-cooled Roots pump can be operated without other roughing pumps, but also flexibly as an intermediate stage of a Roots pumping station. The optional frequency converter can significantly reduce power consumption. The suction speed can be adjusted precisely, and a gentle soft start is possible.

Continuous operation at high pressure differences is made possible by the fact that the gas heated by compression is cooled on the pressure side and partially returned to the suction chamber. In combination with the gas coolers required for optimal process adaptation, applications up to atmospheric pressure are possible. As individual pumps, they can be used in the pressure range from 130 to 1,013 hPa. By connecting two pumps in series, the final pressure can be reduced to 20 to 30 hPa. In combination with other Roots pumps, the final pressure achieved can be reduced to the fine vacuum range. The motors and gas coolers required for operation are adapted to the specific process. Other specific components such as couplings, temperature sensors and base frames to accommodate the solution are available as options.

:grayscale(false):format(webp))

The gas circulation-cooled Roots pumps OktaLine G are characterized by maximum reproducibility in process engineering processes and significantly lower operating costs compared to other vacuum process pumps, such as steam jet pumps or liquid ring pumps.

Customer benefits of the OktaLine G Roots pumps

Large pumping speed range from 4,000 to 12,000 m3/h

Very high continuous pressure differences

Flexibility and process adaptation through design of the motor power and the frequency converter

Thermal process gas control with OktaLine 8000 G and gas coolers

Maintenance-free, maximum reliability and highest uptime thanks to magnetic coupling (optional)

Areas of application of the OktaLine G Roots pumps

Steel degassing

Chemical and process engineering

Helium recovery

Fusion reactors

CombiLine

Combination of Roots pumps with suitable roughing pumps as a pumping station

Roughing pumps such as the DuoLine or R5 rotary vane pumps, the COBRA screw pumps and the ACP multi-stage Roots pumps can be combined very well with the Roots pumps. If necessary, additional stages of Roots pumps can also be added. Our pumping station portfolio CombiLine offers some proven standard configurations here. If you don't find the right combination, we are happy to offer you a customized solution. This means our vacuum pumps can be optimally adapted to the respective application. As a leading provider of vacuum solutions, Pfeiffer has more than 50 years of experience in designing customer-specific systems. Our specialists will be happy to advise you on the optimal design of your vacuum system.

:grayscale(false):format(webp))

:grayscale(false):format(webp))

:grayscale(false):format(webp))

:grayscale(false):format(webp))

:grayscale(false):format(webp))

:grayscale(false):format(webp))